This article will introduce you to the basic knowledge of CNC bending, including the introduction of press brake molds, the forming method of the press brake, the arrangement of the bending process, the selection of positioning benchmarks, the principles of selecting on-site operation machines, and the control method of bending size. I believe you will definitely gain something!

Folding machine mold

1.Folding bed mold

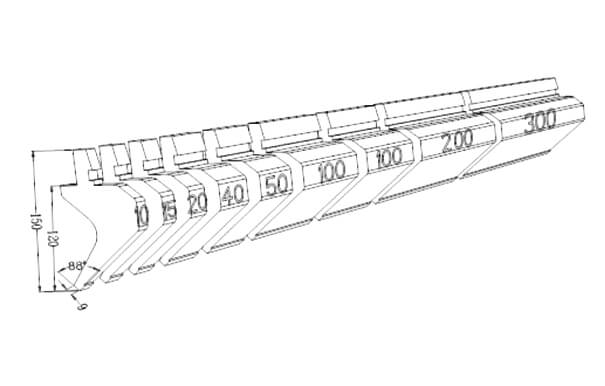

The upper die is also called a folding knife. It is divided into two types: integral and split. The length of the integral upper die is 415mm and 835mm.

Split length: 10, 15, 20, 40, 50, 100 (left ear), 100 (right ear), 200, 300 (mm); the split die can be combined into different bending lengths.

The upper die is divided into four types: straight knife, curved knife, arc knife and special knife.

Types and processing characteristics of straight knives

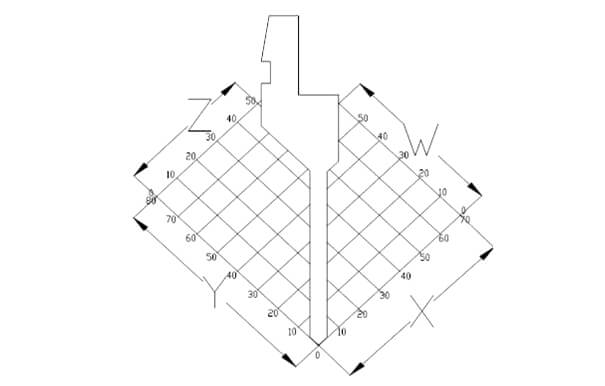

Suitable for bending symmetrical products, can avoid position in both front and back directions, tool thickness is 6MM, so the bending opening can be as small as 6mm.

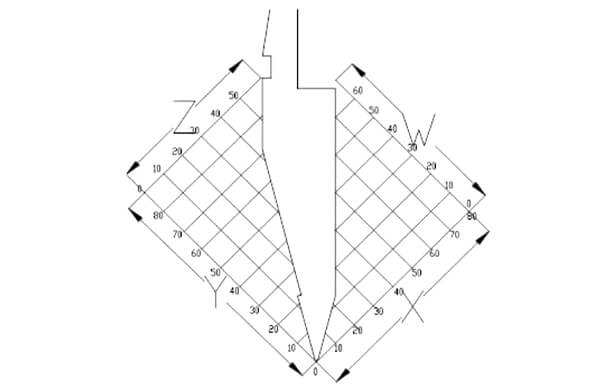

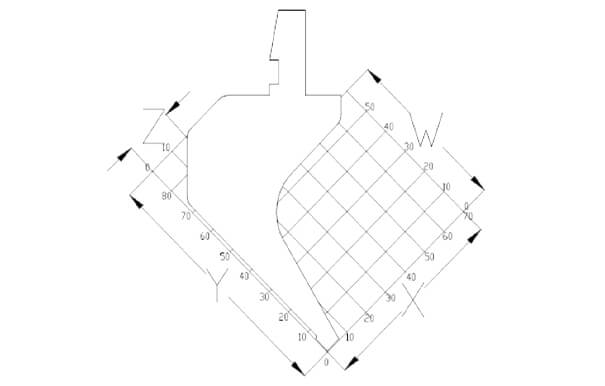

Tool analysis: From the tool bending simulation diagram, we can see that the front and back of the tool can be avoided, but the length of Z and W is smaller than the length of X and Y. The tool tip angle of this tool is 88 degrees, and the tool tip R angle is 0.2. In addition, tools with tool tip angles of 30 degrees and 45 degrees are commonly used.

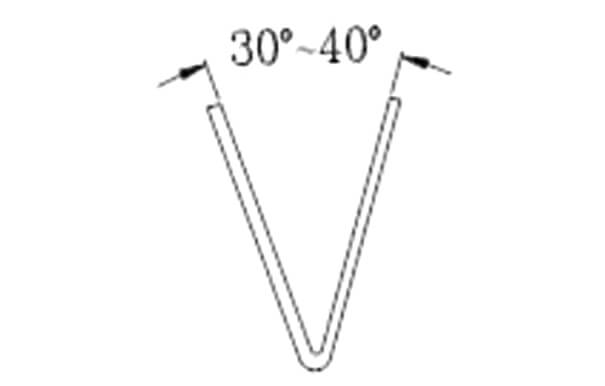

Tool analysis: The tool tip angle is 30 degrees, and the tool tip R angle is 0.67, so the bending angle can be 30 degrees to 180 degrees. The small angle of the tool tip can be used to avoid the bud hole or nut, etc. In addition, it can also be used as a deep insertion mold, and the tool can avoid the front and back.

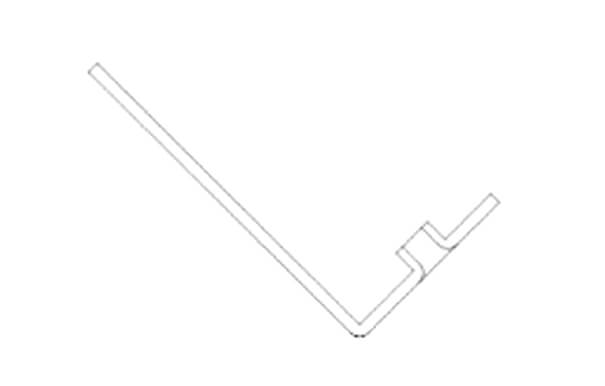

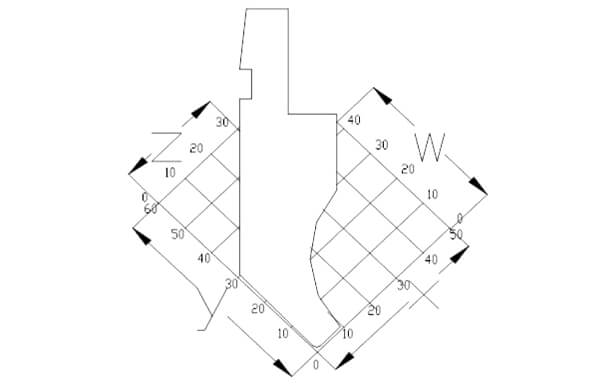

Types and processing characteristics of machetes

Tool analysis: The tool mainly uses the avoidance in the W direction during the bending process. When X>15MM, the avoidance effect becomes worse and worse. When Y>30, the bending conditions are met, otherwise it will hit the back of the tool. This kind of tool is commonly known as a small curved knife.

Tool analysis: The tool mainly uses the avoidance in the W direction during the bending process. When X>25MM, the avoidance effect becomes worse and worse. When Y>75, the bending conditions are met, otherwise it will hit the back of the tool. This kind of tool is commonly known as a large machete.

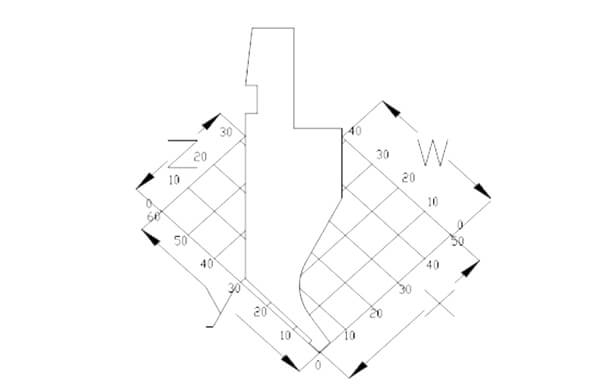

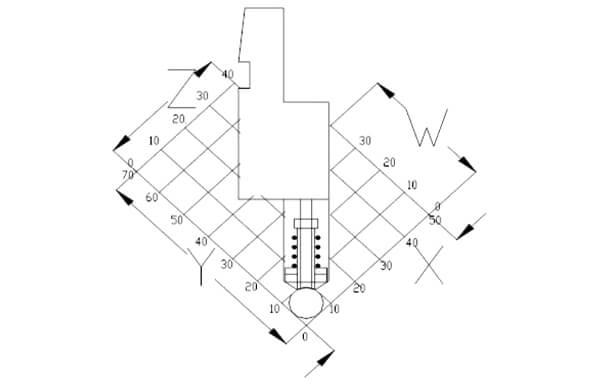

Types and processing characteristics of arc cutters

Tool analysis: Arc tools are divided into fixed and movable types. Arc tools meet different arc bending processing conditions by replacing round bars. When the X dimension of the fixed arc tool is >10MM, its avoidance effect is the same as that of the small curved tool. The popular selection standard of the lower die V groove is the diameter of the arc plus two plate thicknesses.

Types and processing characteristics of special tools

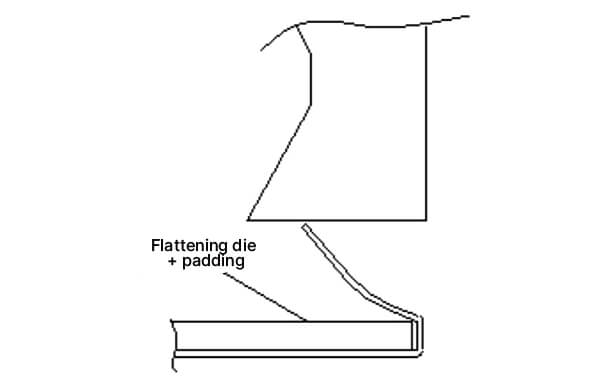

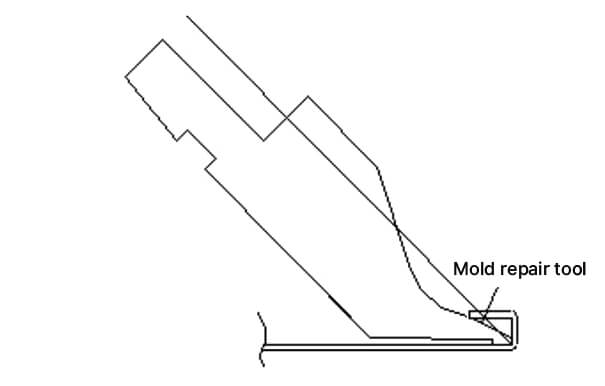

Special tools for folding machines include step-down dies, flattening dies and some special-shaped bending upper dies.

A: The existing step-down dies are divided into two types: 415mm and 835mm. The size specifications of the segmented shapes are consistent with the specifications of the tool segmentation. The bending shapes shown in the figure are formed. However, when the plate thickness is thicker, such as T=2.0, it will be difficult to form considering the severe indentation and the limitations of the die itself.

B: The upper die of the flattening die is a flat die, and the lower die can be replaced by a common bending lower die, but avoid the V groove. It is mainly used for processing methods such as dead edge flattening and riveting nuts.

2.Bending die

The lower die of the folding machine includes bending lower die, inserting lower die, flattening lower die, etc.

Bending die

The selection of the bending lower die of the folding machine is mainly based on the plate thickness of the processed product. At present, the lower die selection standard of Yixin Company is 6T, which is used as the standard for on-site operations unless there are special circumstances. When large V or small V groove processing is required due to processing restrictions, the bending coefficient needs to be adjusted accordingly.

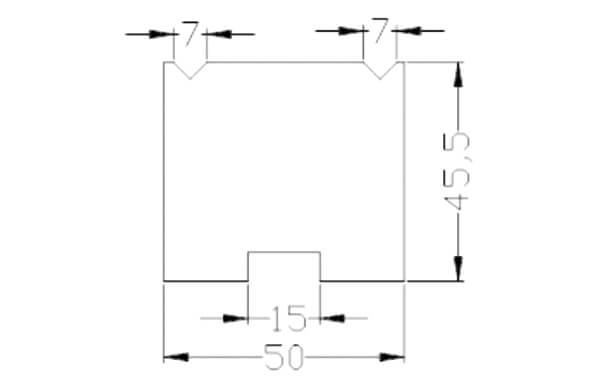

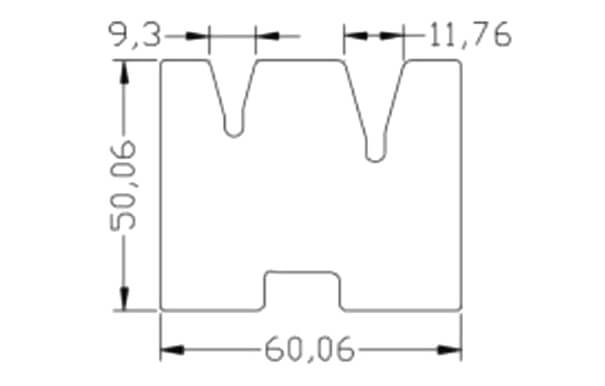

Mold analysis: The figure shows one of the types of lower molds. The types of V grooves mainly include 4V, 6V, 7V, 8V, 10V, 12, 16V, 25V and some special large V groove bending tools. This type of bending lower mold is mainly divided into 46 high and 26 high according to the height. Corrosion, moisture, mildew.

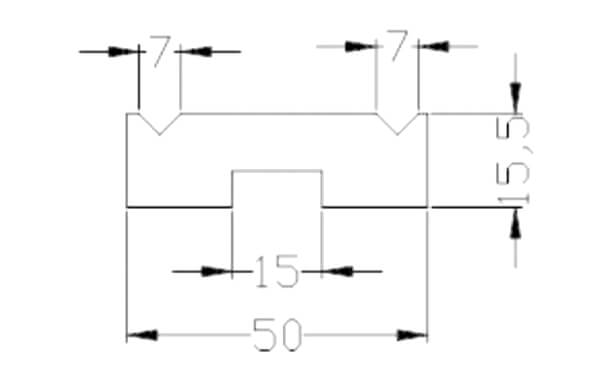

Insertion depth

Mold Analysis: The figure shows one of the deep insertion dies. The types of V grooves mainly include 4V, 6V, 8V, 12 and some special deep insertion dies, which are suitable for bending and deep insertion at any angle between 30-180 degrees.

Flatten the lower die

At present, the company does not have a dedicated flattening die, and generally uses a bending die instead.

Forming method of folding machine

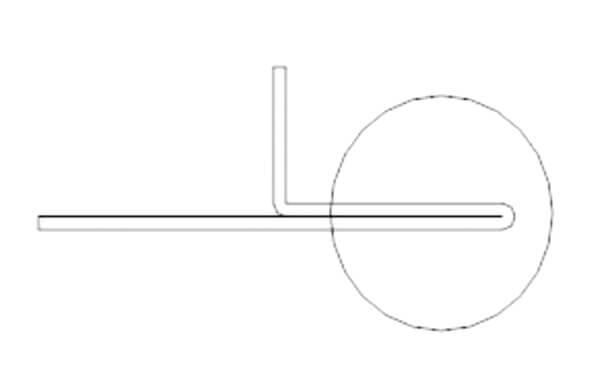

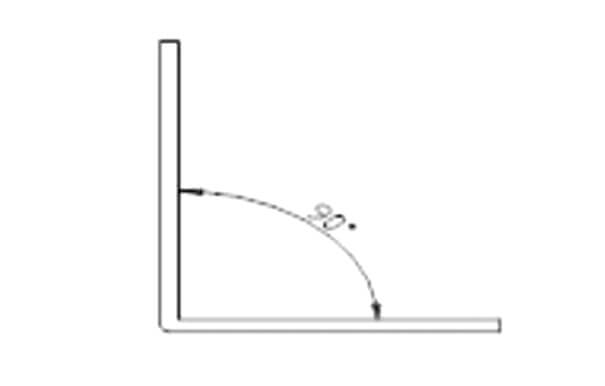

1.L-fold processing

The basic shape of the bend, the bending angle is between 30 degrees and 180 degrees.

When bending sharp angles, you need to select a deep lower die and a sharp upper die. You can choose any die to bend 90 degrees or obtuse angles.

Positioning principle of L-bending processing

A: The principle is to use two rear gauges for positioning (two points) and position according to the shape of the workpiece.

B: When positioning a rear gauge, pay attention to the deflection and require it to be on the same center line as the bending size of the workpiece.

C: When bending small bends, reverse positioning is the best.

D: It is better to position it slightly below the middle of the rear gauge (the rear gauge is not easy to tilt when positioning).

E: The positioning edge is better if it is close to the rear gauge.

F: It is better to position it with the long side.

G: Use a jig as an auxiliary positioning (bevel and irregular edge positioning and bending).

L Internal Bending Processing Precautions

A: When bending with the mold in place, the rear gauge needs to be pulled back to prevent the workpiece from deforming during the bending process;

B: When bending inside a large workpiece, the workpiece has a large shape and a small bending area, making it difficult for the tool and the bending area to overlap, resulting in difficulty in positioning the bent workpiece or damage to the bent workpiece.

L-Shape Bending Processing Precautions

A: When bending small size, whether the upper die and the rear gauge interfere.

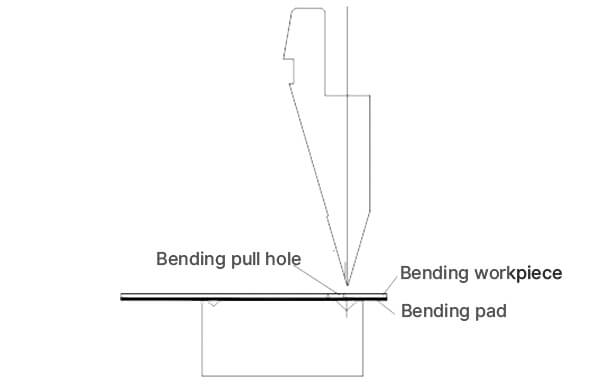

B: When the hole position is close to the bending line or the bending edge size is less than half of the V groove, pay attention to the bending pull.

Special bending method for L-bending

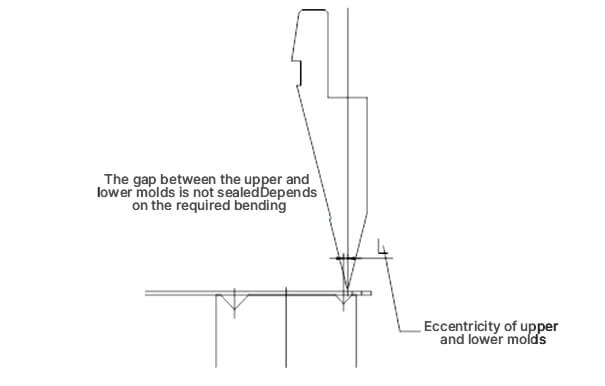

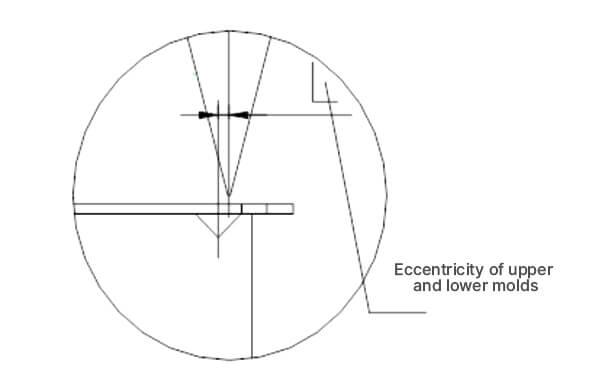

A Eccentric bending method

Process analysis:

Eccentric bending has the difference between positive and negative installation of the lower die. During processing, the difference is made depending on whether the material is on the inside or outside of the bending line. In addition, eccentric bending is a special processing method with certain risks, and it is not used unless under special circumstances.

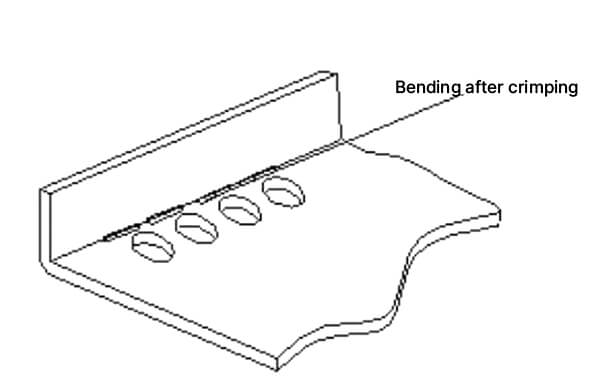

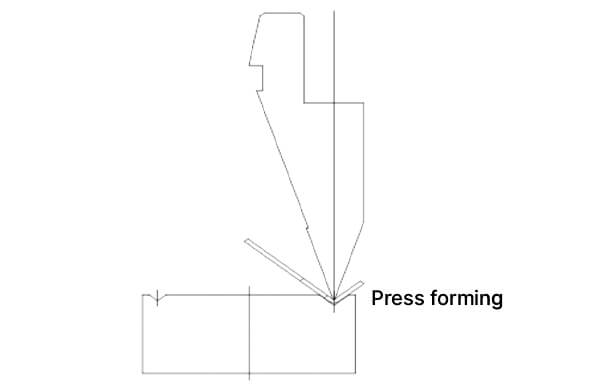

B bending method after pressing

Process analysis:

Since eccentric bending has a shearing effect, it is not suitable for some products with high surface requirements. The timing of line bending is the same as that of eccentric bending. Before bending, you can use an 88-degree tool or a special line-pressing die to press the line at the bending line, and then use a normal die to bend.

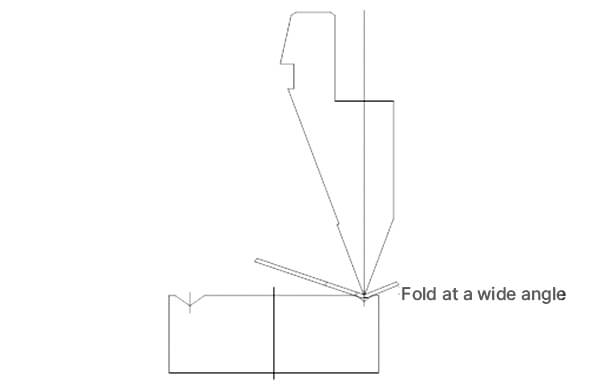

C small V fold large angle large V pressure

Process analysis: First use a small V groove to bend into a large angle, and then use a normal mold to bend. This processing method can avoid the small unfolded size caused by direct bending of the small V groove.

D Add gasket and bend the material

Process analysis: This processing method is mostly suitable for products with strict requirements on the appearance of the workpiece. In addition, due to cost considerations, it is mostly limited to sample processing.

The above four processing methods can also be used in combination, and the molding effect will be more ideal.

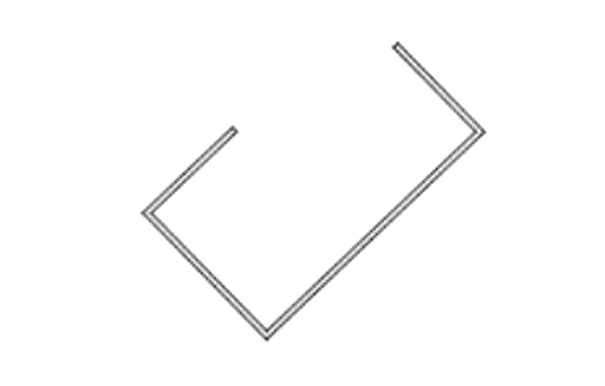

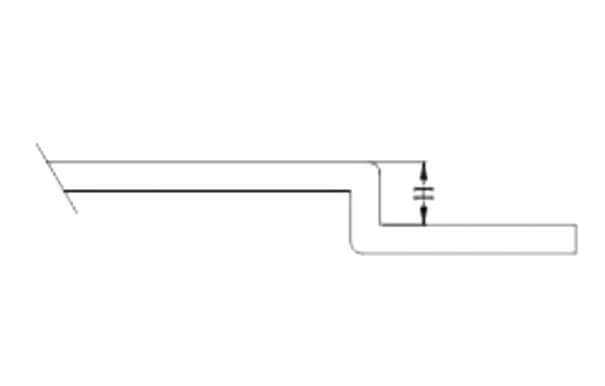

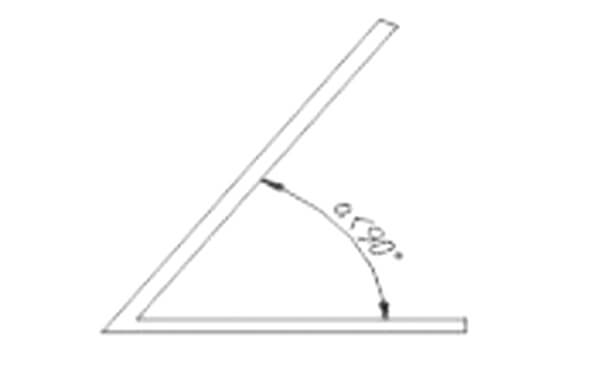

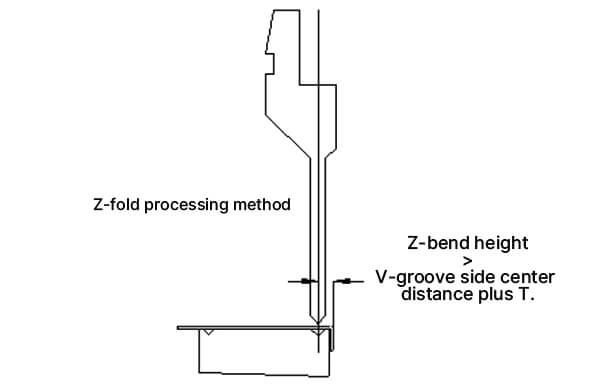

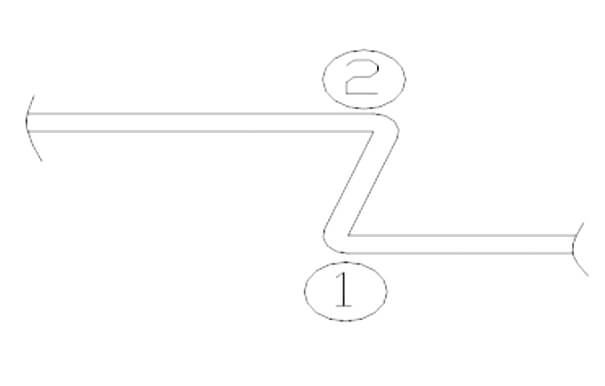

2.Z-fold processing

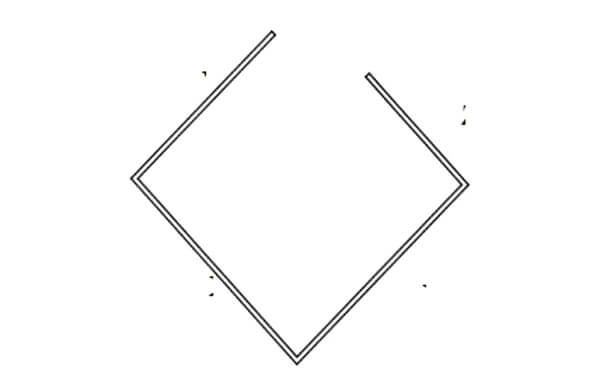

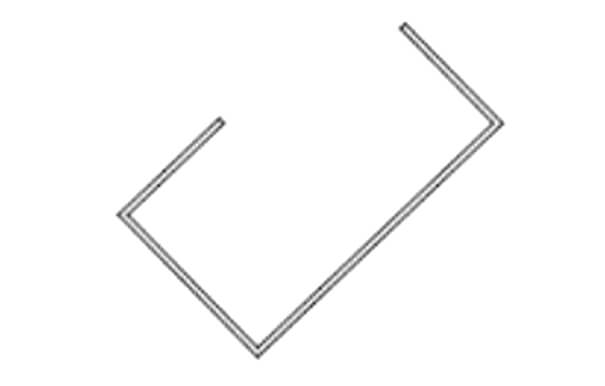

Definition: Any bend that is formed into one reverse and one positive is a Z-type bend.

Standard bend processing range: Z-bend height > V-groove side center distance plus T.

The minimum processing size is limited by the mold used in the processing, and the maximum processing size is determined by the shape of the processing machine.

Z processing Z steps

A: First process the L-fold according to the L-fold processing method;

B: Process the Z-fold with the L-fold in place;

(Or process the Z-fold with the other side of the L-fold.)

The principle of positioning for Z-bending in Z-machining

A: The positioning is convenient and has good stability;

B: The general positioning is the same as the L-bending;

C: The workpiece is required to be flush with the lower die during the secondary positioning process.

Z processing precautions

A: The processing angle of the L-bend must be in place, generally requiring about 89.5 degrees to 90 degrees;

B: The back gauge must be set to pull back to prevent the workpiece from deforming.

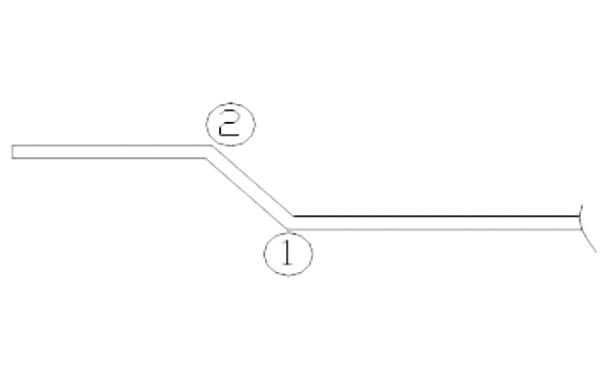

ZGeneral processing method

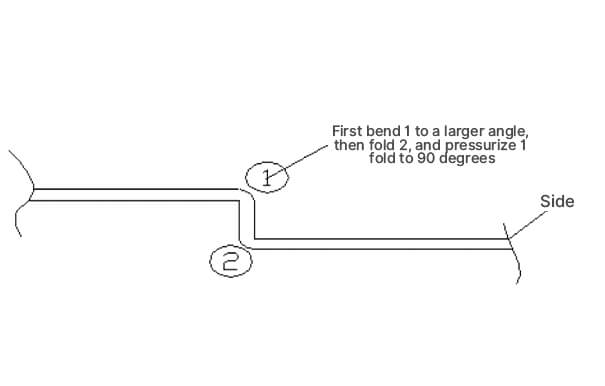

AIn the figure below, the processing order should be considered, first bend 1 and then bend 2.

B Another type is to first fold L and then Z, and confirm whether the Z folding process interferes with the machine.

a: If there is interference, first bend 1 to a large angle, then fold 2, and then press 1;

b: If there is no interference, follow the general Z folding method, first fold 1 and then fold 2.

C: Two sharp angle Z-folds, first bend to 90 degrees, then insert to a depth of 2 and then to a depth of 1.

Special processing method of Z-bending:

A: Eccentric processing of the lower die;

B: Processing with a small V-groove;

C: Bend at a large angle first and then pressurize;

D: Use grinding of the lower die.

Other Z-bending processing methods:

A: Processed with step-down mold;

B: Processed with easy mold.

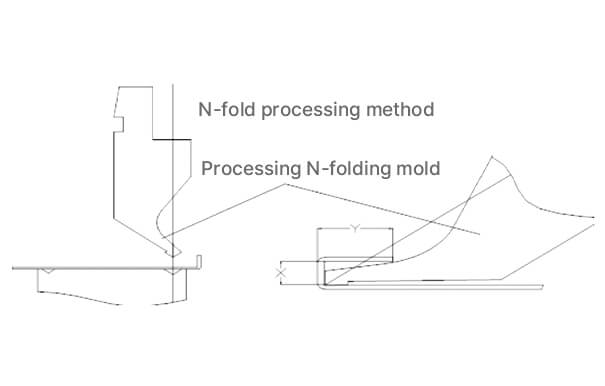

3.N-fold processing

Definition: Continuous processing twice on the same processing surface is called N-fold processing.

General processing precautions for N-fold:

A: The first folding angle should be less than or equal to 90 degrees;

B: When processing the second fold, the final gauge should be based on the processing surface as the reference surface.

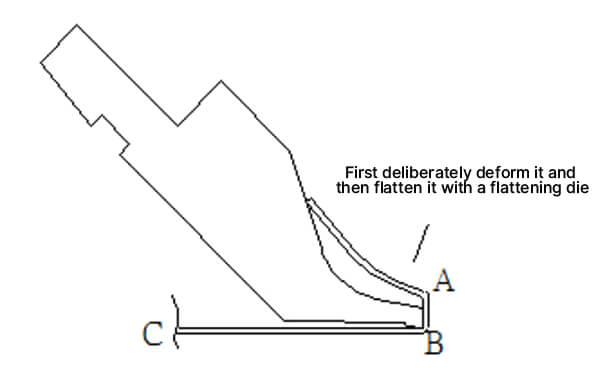

Special processing method of N-fold:

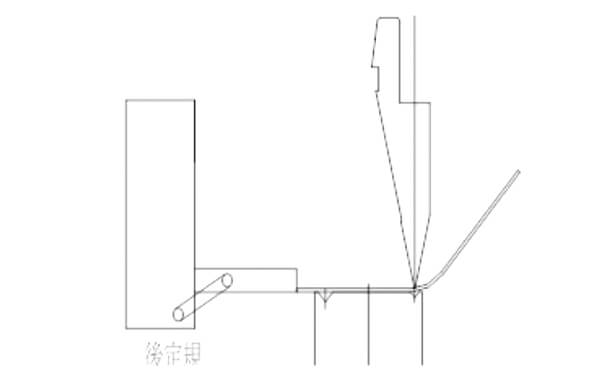

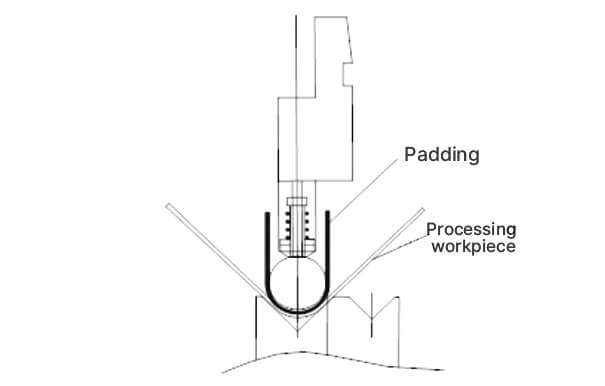

A. When the Y dimension of the N-fold slightly interferes with the upper die ==> Bend the N-fold and then use the flattening die to shape it

B. When the Y dimension of the N-fold greatly interferes with the upper die

==> Bend A to the interference point after the press line, bend B with C, and then use (flattening die + padding) to shape it

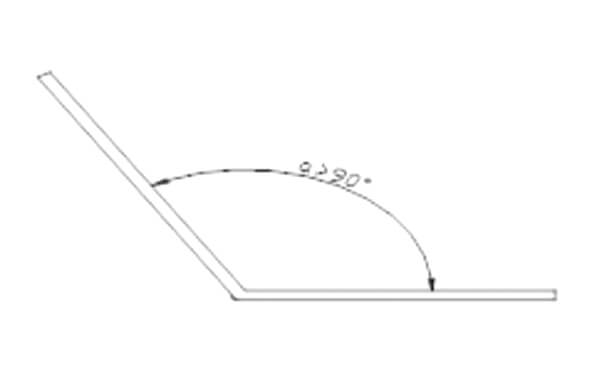

4.Arc processing

Arc processing is divided into two types: cutting with a bending die and processing with an arc knife. The arc knife is divided into two types: fixed type and round bar type.

Processing Notes:

A: When using a 90-degree lower die for processing, the workpiece may not be processed properly, so you need to push it by hand or choose an 88-degree lower die if conditions permit;

B: Use inspection jigs to ensure the appearance and size of the workpiece;

C: When processing a 90-degree arc, choose 2 (R+T) for the lower die.

Bending process arrangement

1.Basic principles of bending process arrangement

A. Bend from inside to outside

B. Bend from small to large

C. Bend the general shape first, then the complex shape

D. The principle is that the bending in the previous process does not affect the subsequent process

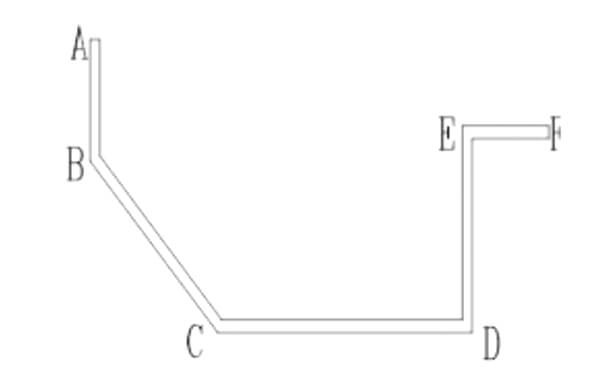

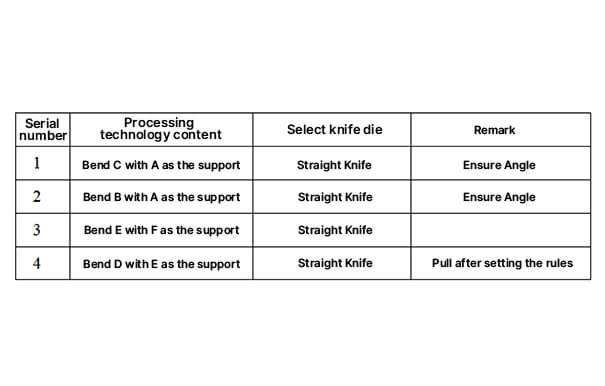

2.Process Scheduling Example

No matter how complex the workpiece is, it is composed of several processing methods. Therefore, it is necessary to master the operation method of each bending method and learn to integrate and apply it, so that the bending process can be reasonably arranged for different workpiece shapes in the operation.

Selection of positioning reference

A. Positioning by the nearest edge;

B. Positioning by the wide edge;

C. Positioning by the unfolded edge or the less-bent edge as much as possible to reduce the cumulative error;

D. Positioning by the edge without burrs and joints for punching workpieces;

E. Positioning by the edge with small deformation of the workpiece;

F. Try to choose two post-positioning positions;

G. Auxiliary positioning can be added at both ends of the mold, such as magnets;

H. For irregular workpieces, use LASER cutting positioning fixtures for positioning;

I. Do not choose positioning for large angles or U-shaped bends.

Principles for selecting on-site operation machines

A. Select the machine according to the bending width;

B. Select the machine according to the bending length;

C. Select the machine according to the pressure required for bending;

D. Select the machine according to the number of processing stations;

E. Select the machine according to the different types and quantities of machines on site;

F. Select the machine according to the special requirements of the mold;

G. Select the machine according to the avoidance requirements;

H. Select the machine according to the moving range of the post-regulation;

I. Select the machine according to the shape of the post-regulation.

Bending size control method

A. Avoid cumulative errors, and measure the unfolded dimensions after each fold;

B. Avoid positioning with the already bent edge, and avoid positioning at a large angle;

C. For products that must be positioned with the already bent edge, the angle of the previous fold should be slightly less than 90 degrees;

D. Determine the accuracy of the measuring tool before processing;

E. Perform the first inspection before formal processing, and perform inspections during processing;

F. Select the appropriate machine according to the accuracy requirements of the processed product;

G. Avoid selecting tools with different centers, and confirm that the upper die tip is in the same straight line before processing;

H. Select a good processing method and a good process arrangement method to simplify the processing difficulty;

I. Accurate positioning, and immediate detection is required for positioning abnormalities.

Quiénes somos

Durmapress se especializa en el diseño, la fabricación y la venta de diversos equipos de procesamiento de metales, como plegadoras, cizallas, punzonadoras, máquinas de corte por láser, etc. La empresa se fundó en 2000. Con años de experiencia y acumulación de tecnología. DurmaPress se ha convertido en una de las marcas más conocidas de la industria china de maquinaria para el procesamiento de metales.

Póngase en contacto con nosotros

Entradas recientes

Categorías

Síguenos

Nuevo vídeo semanal

Más información

Si tiene alguna información sobre nuestros productos, póngase en contacto con nosotros y le responderemos en 24 horas.

-300x169.jpg)