Shearing machine is a machine that uses one blade to cut the plate in a reciprocating straight motion relative to another blade. By using the moving upper blade and fixed lower blade, the reasonable blade clearance is used to impose shear force on the metal sheet of various thickness, so that the plate can be broken and separated according to the required size. Shearing machine belongs to one of the forging machinery, the main role is the metal processing industry. The products are widely used in aviation, light industry, metallurgy, chemical industry, construction, shipbuilding, automobile, electric power, electrical appliances, decoration and other industries to provide special machinery and complete sets of equipment needed.

Use of Q11-2x1000 electric plate shears

Shearing machine is a kind of shearing equipment widely used in machining, it can shear various thickness of steel plate materials. The commonly used shearing machine is divided into three types: flat shear, rolling shear and vibration shear. Flat shears are used a lot. Shearing thickness less than 10mm for mechanical transmission, more than 10mm for hydraulic transmission. Single or continuous shearing of metal is usually done by foot or button operation. Attention should be paid to the operation of plate shears:

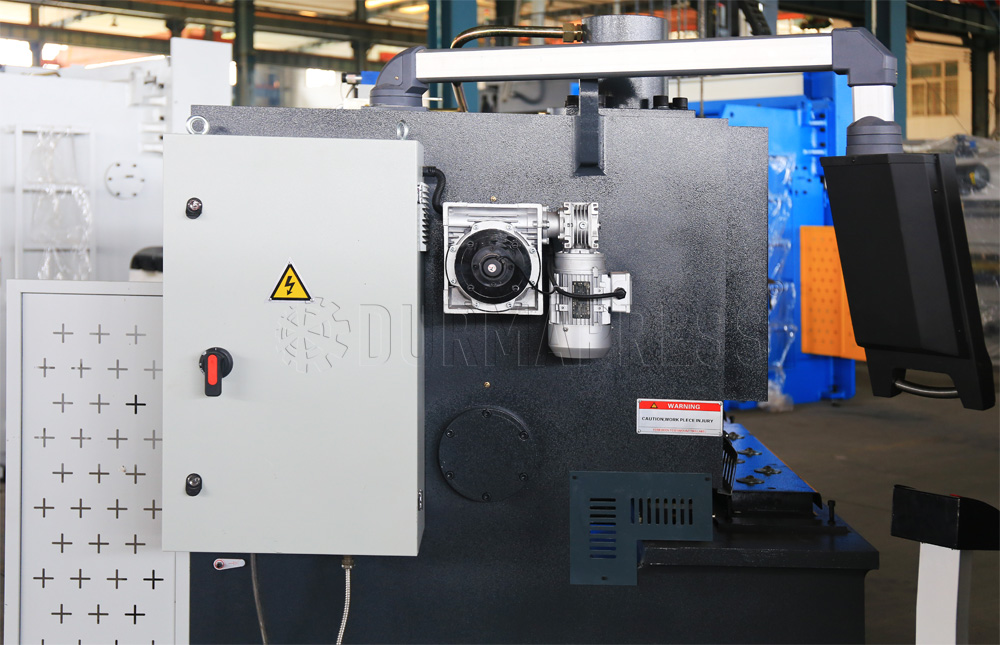

1. Before work, carefully check whether the shearing machine is normal, whether the electrical equipment is in good condition, and whether the lubrication system is smooth; Remove tools, measuring tools and other debris and corner waste placed on and around the table.

2. Do not operate the shearing machine alone, should be coordinated by 2-3 people for feeding, control dimensional accuracy and material, and determine the unified command by 1 person.

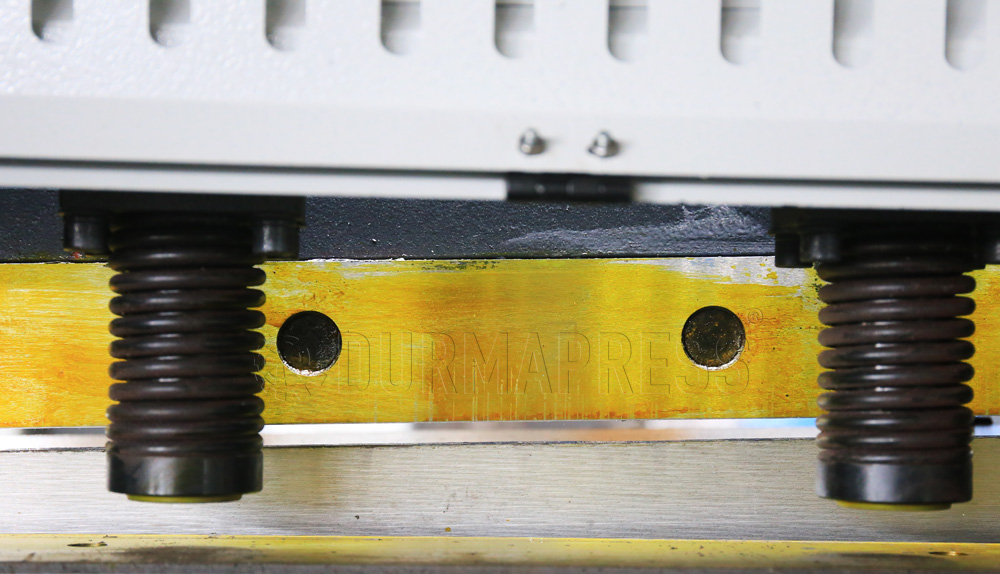

3.According to the specified thickness of the cutting plate, adjust the scissors clearance of the shearing machine. Do not cut two different specifications, different materials of the board at the same time; Do not stack and cut. The shearing sheet requires a flat surface and is not allowed to shear the narrow sheet which cannot be compressed.

4. The belt, flywheel, gear and shaft of plate shearing machine must be installed with protective cover.

5. The feeding finger of the shearing machine operator should be kept at least 200mm away from the mouth of the scissors, and leave the pressing device. The protective bars placed on the shearing trigger should not block the operator's eyes from seeing the cutting site. The waste generated after the operation has edges and corners, the operator should remove in time to prevent being stabbed and cut.

6.Plate shearing machine flywheel, gear, shaft, tape and other moving parts should be set up protective cover.

7. Place a fence to prevent the operator's hands from entering the scissor drop area. When working, it is strictly prohibited to pick up waste materials on the ground, so as not to be hurt by falling workpieces.

8. Do not cut the quenched material, and never allow cutting to exceed the working capacity of the cutting machine.