características

- Adecuada para curvar placas ultralargas.

- Combinando tres máquinas, consigue un proceso de producción altamente automatizado gracias a una avanzada tecnología de automatización.

- Equipada con avanzados sistemas CNC, que pueden lograr un control preciso de cada estación de plegado.

- Mayor profundidad de garganta, recorrido y luz diurna para mejorar el rendimiento.

- Cambio de herramientas y alineación eficaces para agilizar las operaciones.

- Simplifique los procesos de mantenimiento y reparación para mayor comodidad del usuario.

- Menores costes de producción para mejorar la rentabilidad.

- Utilice componentes de marcas fiables y reconocidas en todo el mundo.

País exportador

0

+

Tasa de satisfacción de los clientes

0

/5

Miembros del equipo profesional

0

Componente ESTÁNDAR

Otros componentes

Cada pieza puede garantizar una larga vida útil y reducir los costes de producción.

Bastidor de la máquina

Las plegadoras Durmapress incorporan un robusto bastidor monobloque fabricado en acero de alto rendimiento, que garantiza una precisión y fiabilidad duraderas. Cada bastidor está templado y respaldado por una garantía de 15 años.

Sistema hidráulico

Nuestra empresa suministra controladores de primera calidad procedentes de marcas prestigiosas como Delem, ESAy Cybelec. Estos controladores se importan directamente de reputados centros de fabricación situados en los Países Bajos, Italia y Suiza, respectivamente.

Calibre trasero

Utilizamos husillos de bolas y guías lineales PMI de Taiwán para la precisión del eje X, lo que garantiza una mayor precisión que los sistemas basados en varillas. El tope trasero, controlado por un servomotor con un mecanismo de correa dentada y rueda, ofrece un posicionamiento preciso.

Motor

Los servomotores son el estándar de la industria por su eficiencia energética, rendimiento dinámico y mayor productividad de la máquina. En comparación con los motores convencionales, pueden ahorrar hasta 35% de energía, lo que garantiza una mayor eficiencia y menores costes operativos.

Abrazadera rápida lateral

Revolucione la eficiencia de su producción con la posibilidad de intercambiar sin problemas los punzones superiores. Al agilizar el flujo de trabajo, esta función garantiza un proceso rápido y eficiente a la hora de adaptarse a los distintos requisitos de plegado.

soporte delantero

El soporte de material delantero de la plegadora es un dispositivo que se utiliza para apoyar y posicionar las piezas de trabajo metálicas durante las operaciones de plegado. El material de soporte frontal ayuda a evitar que la pieza de trabajo se pandee o se doble, garantizando la precisión y la calidad del plegado.

Servomotor del eje R

El servomotor del eje R es un componente crucial en el funcionamiento de una plegadora. Específicamente dedicado a controlar el eje de plegado, el servomotor del eje R desempeña un papel fundamental en la consecución de precisión y exactitud durante el proceso de plegado.

armario eléctrico

Aprovechando la fiabilidad de los componentes originales Schneider procedentes directamente de Francia, famosos por su estabilidad inquebrantable, su impresionante durabilidad y su prolongada vida útil.

Sistema hidráulico

Característica de alta calidad Rexroth válvulas hidráulicas para una mayor durabilidad y un mantenimiento mínimo. Nuestras máquinas realizan diversas acciones, como descenso rápido, descenso lento, plegado a velocidad de trabajo, retorno rápido y parada de emergencia.

Ball Screw & Guide

La máquina está equipada con husillos de bolas de precisión y raíles de guía lineal, que proporcionan un funcionamiento suave y fiable que mejora el rendimiento general. Este avanzado sistema garantiza movimientos precisos, reduce la fricción y contribuye a la longevidad de la máquina, lo que la convierte en la opción ideal para aplicaciones exigentes.

Componente OPCIONAL

Otros componentes

Accesorios de primera calidad de las principales marcas internacionales

Coronación

Para garantizar ángulos de plegado precisos y uniformes en toda la longitud de la pieza, independientemente del grosor del material, reduciendo los desechos y mejorando la eficiencia. Mejora la versatilidad de la prensa plegadora compensando la desviación de la matriz, garantizando que el producto final cumpla las especificaciones deseadas con ángulos de plegado precisos. Este ajuste de la forma de la bancada contrarresta la desviación de la matriz, garantizando unos doblados precisos según las especificaciones.

Punches & Dies

La selección de punzones y matrices para prensas plegadoras es un tema crucial que debe discutirse antes de realizar un pedido. Cualquier forma de plegado deseada se consigue mediante el uso de un conjunto adecuado de punzones y matrices. Ofrecemos una gama de opciones de utillaje adecuadas para satisfacer los diversos requisitos de plegado de nuestros clientes.

LaserCheck Medición del ángulo de curvatura

Experimente una precisión sin igual con el sistema de medición de ángulos iMeasure Laser en colaboración con Data-M Engineering, que garantiza ángulos de curvatura exactos con una sola operación.

Protección láser DSP

El sistema de protección láser DSP supervisa la intensidad y la ubicación de la radiación láser en tiempo real para garantizar que cualquier posible riesgo para la seguridad láser pueda detectarse a tiempo cuando la plegadora esté en funcionamiento.

Seguidores de chapa controlados por CNC

Los últimos seguidores para el plegado de chapa pretenden optimizar las prestaciones de nuestras plegadoras reduciendo el tiempo de puesta a punto de la plegadora y simplificando el trabajo de los operarios. Estas ayudas al plegado proporcionan a los operarios una valiosa asistencia práctica.

portaherramientas wila

Utilizamos las tecnologías innovadoras de WILA, incluyendo Safety-Click®, Smart Tool Locator® y el sistema de reemplazo E2M® para herramientas (de trabajo pesado), para mejorar la seguridad y conveniencia del reemplazo. La precisión y la ergonomía se adaptan cuidadosamente para obtener la máxima productividad de todas las herramientas.

Pida presupuesto ahora

Obtenga más detalles sobre la Plegadora CNC Servo Tridem de DURMAPRESS

Características estructurales de los cilindros hidráulicos

Nuestros cilindros hidráulicos están fabricados con acero aleado de alta calidad para ofrecer durabilidad y fiabilidad.

- Válvula de cartucho de dos vías: Diámetro Dg16-Dg160, rango de caudal 63 L/min-15000L/min.

- Válvula de llenado de líquidos: Diámetro Dg40-Dg400, rango de caudal 300L/min-35000L/min.

- Válvulas de corredera de placa tradicionales: Incluyen válvula de alivio, válvula de secuencia, válvula unidireccional, válvula direccional solenoide, válvula unidireccional de control hidráulico, válvula de mariposa, válvula de control de flujo.

- Barril del cilindro: Fabricado en acero de aleación de alta calidad para mayor solidez y resistencia al desgaste.

- Pistón: Forma una cavidad estanca con el cilindro, transmitiendo la fuerza mediante presión hidráulica.

- Juntas: Importantes para sellar y evitar fugas y contaminación.

- Puerto de aceite: Entrada y salida para la entrada, salida y ajuste de la presión del aceite hidráulico.

¿Por qué elegirnos?

1

tecnologías innovadoras

Utiliza tecnologías innovadoras en sus máquinas, incorporando características que mejoran el rendimiento, la precisión y la eficacia.

2

Sistema opcional

Las máquinas DurmaPress vienen equipadas con características innovadoras, como sistemas de control avanzados, procesos automatizados y dispositivos de seguridad.

3

Control multieje

DurmaPress ofrece una amplia gama de maquinaria para la fabricación de metal, que satisface las distintas necesidades de la industria.

fábrica de durmapree

Ver el vídeo

Fabricante de equipos punteros de tratamiento de metales

fábrica de durmapree

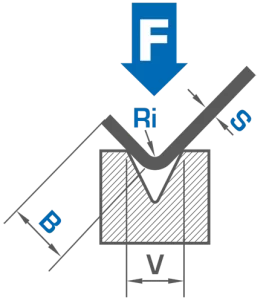

calculadora de parámetros de flexión

¿Cuánta fuerza necesita para doblar su pieza

Cálculo de la fuerza de flexión

¿Cuánta fuerza necesitas para doblar la pieza?

fábrica de durmapree

Equipos de procesamiento

Fabricante de equipos punteros de tratamiento de metales

Póngase en contacto con nosotros

Ubicación

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Póngase en contacto con nosotros

Teléfono : + 86 183 2557 2889

Correo electrónico : [email protected]

Nuestro horario

7/24

Síguenos