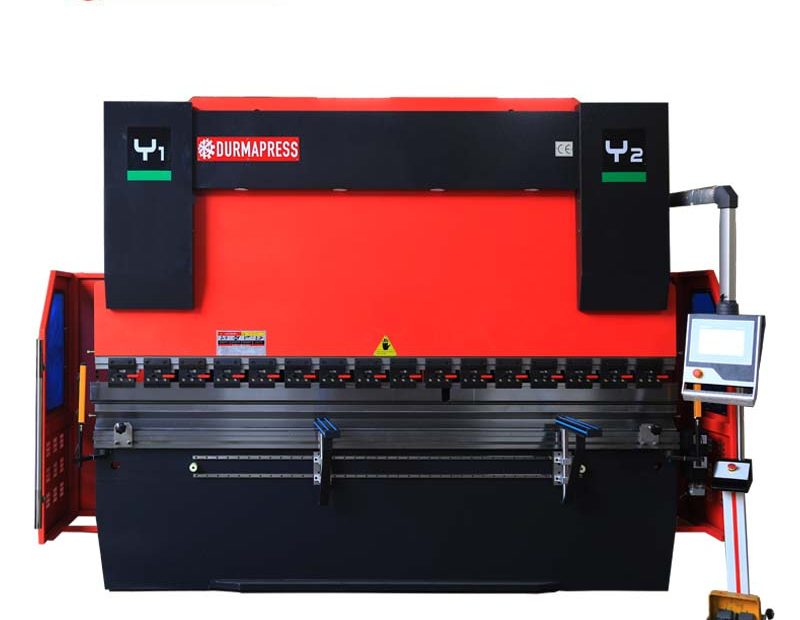

WC67Y series bending machine CNC system functions

WC67Y series bending machine CNC system functions: 1, With one-way and two-way positioning function, can effectively eliminate the lead screw 2. It has the function of conceding and selecting material, avoiding the interference between the material retaining device and the workpiece, reducing wear and improving positioning accuracy. 3, Hydraulic plate bending machine has automatic or manual search reference point function.With the function of power off location memory, parameters, location and program for on-site protection. 4, With the function of multi-step… Leer Más "WC67Y series bending machine CNC system functions