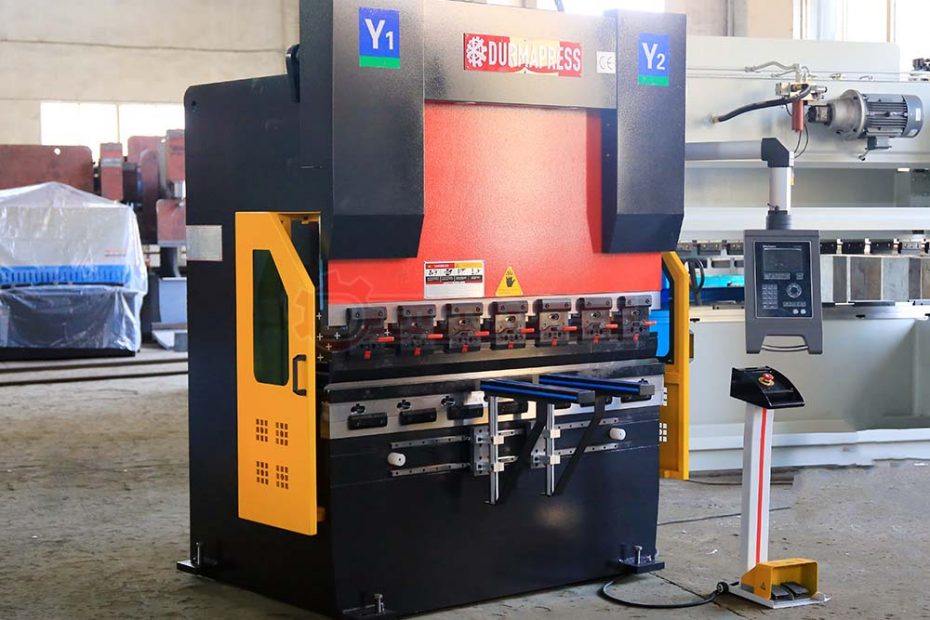

Safety management system of hydraulic press brake machine

Safety management system of hydraulic press brake machine First, before work (1) Fill lubricating oil according to the provisions of the lubrication chart, and check whether the oil quality and oil quantity meet the requirements. (2) Check whether the equipment and control parts, buttons are in the correct position. (3) Check the coincidence degree and fastening of the upper and lower die; Check whether the positioning devices meet the requirements of the workpiece being processed. (4) The equipment starts up… Leer Más "Safety management system of hydraulic press brake machine