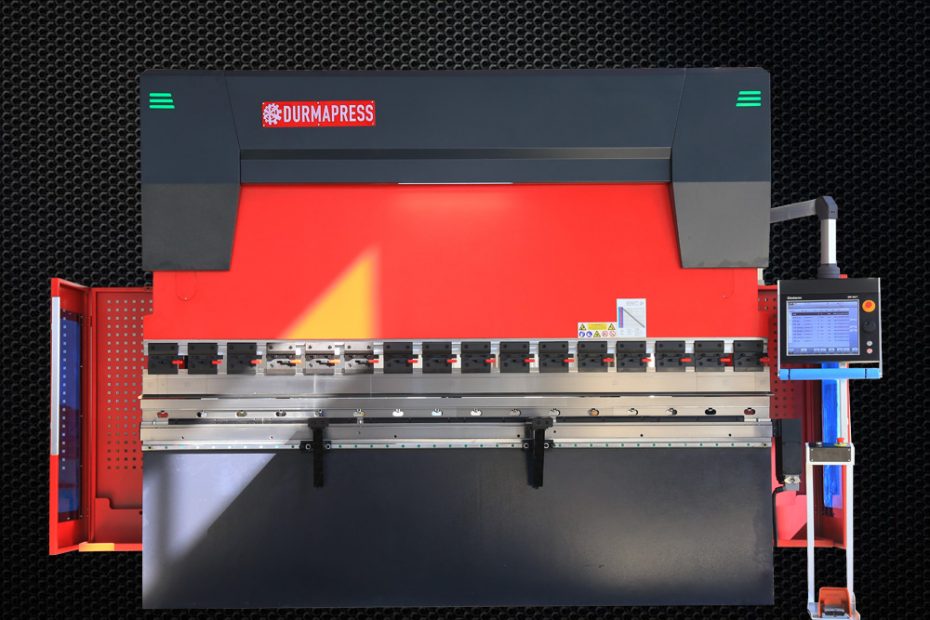

S 600 Series

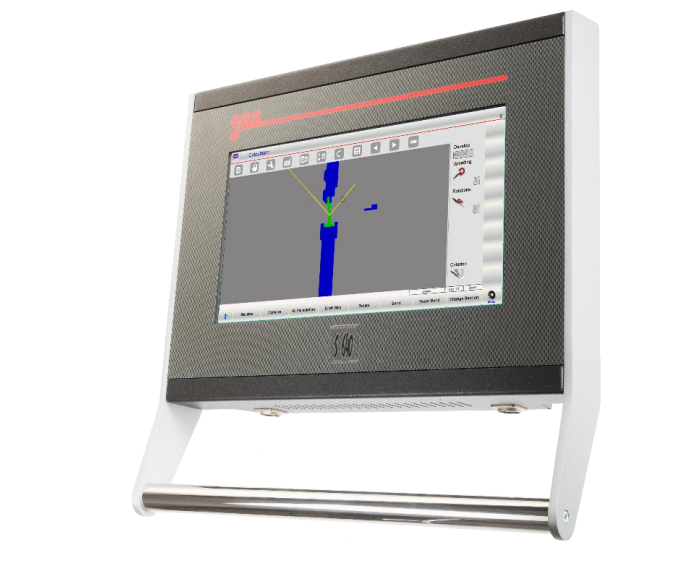

The most powerful CNC controller in its class. Graphical programming at the highest level with a large 15 '' touch screen for maximum ease of use to get the most out of your machine. General software functions Numerical and graphical 2D programming with automatic calculation of the Y-axis based on tool, material and programmed angle as well as automatic calculation of the position of the X, R or Z axis Graphical 2D tool programming Automatic calculation of the bending force… Leer Más "S 600 Series