introduction

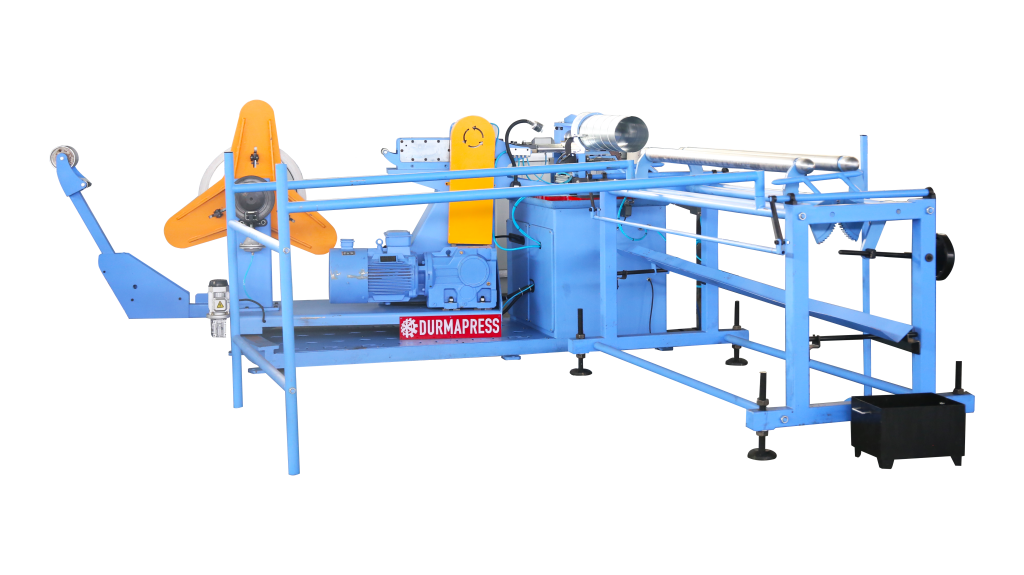

In today's industrialization process, Spiral Duct Forming Machine , as an important production equipment, plays a vital role in ventilation, refrigeration, fire engineering and other fields. It not only improves the production efficiency, but also greatly promotes the improvement of product quality, and injects new vitality into the prosperous development of engineering construction and manufacturing industry.

Overview and application background of Spiral Duct Forming Machine

Definition and function of Spiral Duct Forming Machine

Spiral Duct Forming Machine , as the name suggests, is a kind of mechanical equipment specialized in processing common plate flange. Through advanced processing technology and precise control system, it can efficiently produce common plate flange products that meet the standard requirements. As an important part connecting pipelines, equipment and other components, the quality and precision of the common plate flange directly affects the stability and safety of the whole system. Therefore, the function of Spiral Duct Forming Machine is particularly important. It can not only realize automatic production and improve production efficiency, but also ensure the precision and quality of the products to meet the needs of use under various complex working conditions.

In the fields of ventilation, refrigeration and fire-fighting engineering, Spiral Duct Forming Machine plays a vital role. It not only improves the sealing and stability of piping system, but also reduces the occurrence of leakage and safety hazards. In addition, with the continuous development and progress of the construction industry, the requirements for piping systems are getting higher and higher. As an efficient and precise production equipment, Spiral Duct Forming Machine has become an indispensable and important part in these fields.

Market application of Spiral Duct Forming Machine

With the continuous maturity of Spiral Duct Forming Machine technology and the continuous expansion of application fields, its market demand is also growing yearly. In the engineering construction and manufacturing industry, the Spiral Duct Forming Machine has become one of the important production equipment of many enterprises. Enterprises in different fields actively introduce and use Spiral Duct Forming Machines to improve production efficiency and product quality.

Secondly, the formulation of safety regulations can improve the stability and reliability of the equipment. Through strict control and supervision of the equipment operation process, the faults and hidden dangers of the equipment can be found and eliminated promptly to ensure the normal operation and long-term stability of the equipment. This is important for improving production efficiency and product quality.

Finally, the formulation of safety operation procedures can also enhance the safety management ability of the enterprise. Through the establishment of a sound safety management system and system, it can realize the comprehensive supervision and control of the production process, and improve the safety management of the enterprise.

Pre-operational Preparation

Training Requirements for Operators

Operators are the first line of defense for the safe operation ofSpiral Duct Forming Machines. Therefore, they must receive strict professional training to ensure an in-depth understanding of the working principle and use of the equipment. The training should cover various aspects such as the construction of the equipment, working principle, common troubleshooting and emergency handling techniques. For example, through simulation drills, let the operators familiarize themselves with the emergency response of the equipment in different failure situations and improve their ability to deal with emergencies.

Safety inspection of equipment

Before operation, it is vital to conduct a comprehensive and detailed safety inspection of the coplanar flange machine. This not only ensures that the equipment is in good working condition, but also effectively prevents safety accidents caused by equipment failure. Inspection points include, but are not limited to, whether the wire connections are firm, whether the fasteners are in good condition, and whether the lubrication system is normal. At the same time, should emphasize the importance of checking the work, requiring operators to carry out the necessary checks before each operation to ensure that the equipment is safe and secure.

Safety Operation Procedures

Correct starting and stopping procedure

The startup, operation and shutdown process of the coplanar flange machine should follow strict standard operating procedures. Before starting the equipment, the machine must be checked for jamming or looseness to ensure that it is in normal condition. During the operation of the equipment, the running status of the equipment should be closely monitored, and abnormalities should be found and dealt with in time. When stopping the machine, the equipment should be shut down gradually according to the specified procedures to ensure the safe shutdown of the equipment.

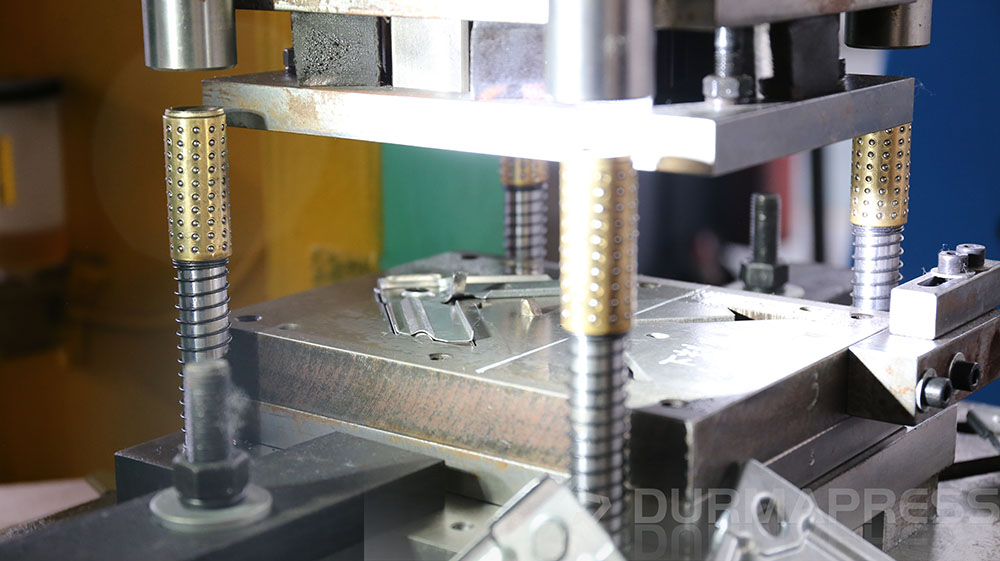

Selection of plates and precautions for use

The selection of compliant plates is vital to the normal operation of theSpiral Duct Forming Machine. Operators should be familiar with and master the selection criteria of compliant plates, such as material, size, thickness, etc.. At the same time, operators should be clearly informed of the potential risks of using non-compliant plates, such as equipment damage, decreased productivity or even causing safety accidents. The importance of compliant plate selection is further emphasized through examples and data analysis.

Routine maintenance and servicing of equipment

Routine maintenance and upkeep is the key link to extend the service life ofSpiral Duct Forming Machine and reduce the failure rate. Operators should master the specific steps and methods of daily maintenance of the equipment, such as regular lubrication, cleaning and replacement of wearing parts. Through vivid cases and practical operation demonstration, the operators will deeply realize the importance of daily maintenance and develop good maintenance habits.

Safety Precautions in Operation

Requirements for the operating environment

The safety requirements of the operation site are directly related to the safe operation of the coplanar flange machine. The operation site should maintain good ventilation and lighting conditions, and the layout of equipment should be reasonable and orderly. At the same time, sundries should be prevented from interfering with the normal operation of the equipment, and the operation area should be kept neat and orderly. Further emphasize the importance of the operating environment to equipment safety through field visits and case studies.

Precautions to avoid hazardous operations

During operation, the operator should strictly observe the safety regulations and avoid dangerous operations. For example, overloading operation and wrong use of plates are strictly prohibited. By listing some common cases of wrong operation and analyzing the consequences, the operators will deeply realize the seriousness and harm of dangerous operation. At the same time, provide suggestions and methods to avoid dangerous operation to ensure that operators can operate the equipment correctly and safely.

Emergency Incident Handling Program

Handling methods for common emergency situations

Detailed handling programs should be formulated for emergencies that may occur in theSpiral Duct Forming Machine, such as sudden stopping of the equipment, electrical failure, and so on. Through simulation drills and actual operation training, the operators should master the handling methods and techniques in various emergency situations. At the same time, the importance of remaining calm and responding quickly in emergency situations should be emphasized.

Operator Emergency Response Training

In order to improve the ability of operators to respond in an emergency, the enterprise should regularly organize emergency response training. The content of the training should include the identification of emergency situations, handling methods and response measures. Through a combination of regular training and emergency drills, operators should be proficient in emergency handling skills and be able to respond quickly in an emergency.

Conclusion

The safe operation of theSpiral Duct Forming Machine plays a vital role in ensuring production efficiency and personnel safety. By strengthening the training of operators, formulating perfect safety operation regulations, strengthening the inspection and maintenance of equipment, and establishing a perfect emergency treatment program, we can effectively reduce the risk of safety accidents and improve production efficiency. At the same time, we also call on operators and companies to share the responsibility of safe operation to create a safe and efficient production environment.

Quiénes somos

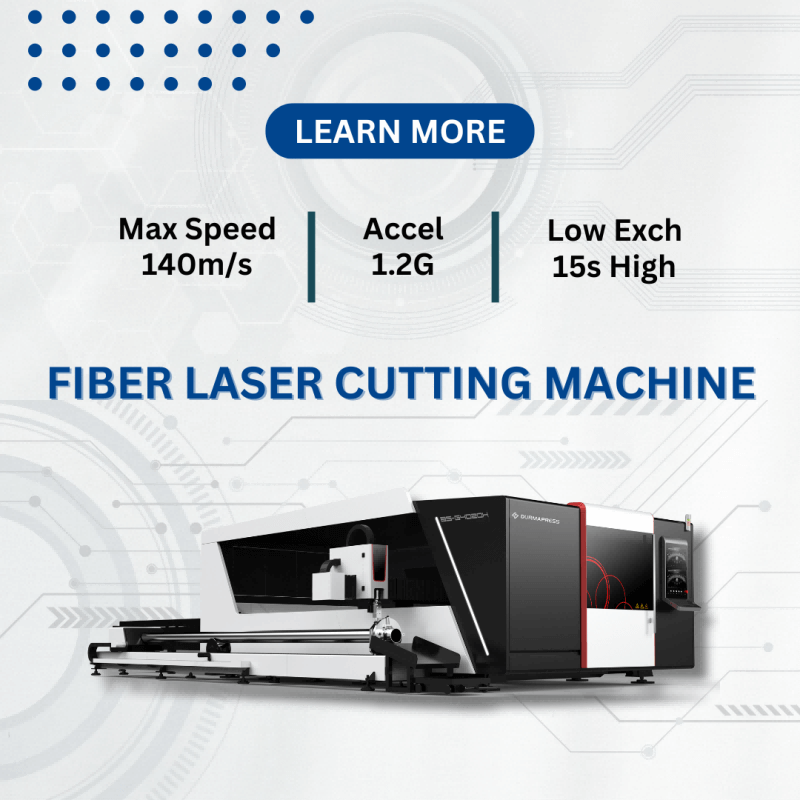

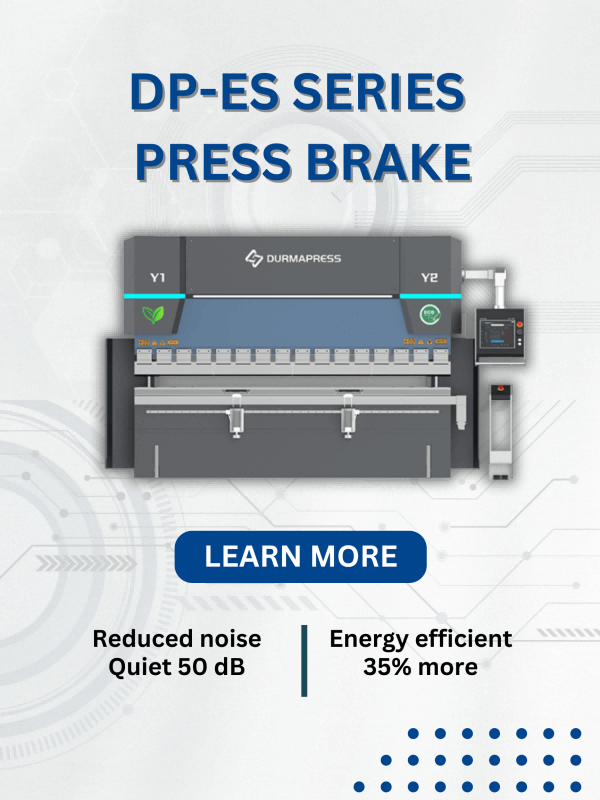

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Póngase en contacto con nosotros

Recent Posts

Categories

Síguenos

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.