características

- Capaz de cortar, perforar y troquelar diversas formas de acero.

- Equipada con un dispositivo de parada de cizalla para mayor seguridad y precisión.

- Utiliza transmisión hidráulica para un funcionamiento eficaz.

- Combina múltiples funciones, como el cizallado de metales, el punzonado, el cizallado de chapas y el plegado.

- Fácil de manejar, requiere una formación mínima.

- Uso eficiente de la energía, lo que reduce los costes de explotación.

- Requiere un mantenimiento mínimo, lo que reduce los gastos generales de mantenimiento.

País exportador

0

+

Tasa de satisfacción de los clientes

0

/5

Miembros del equipo profesional

0

durmapress

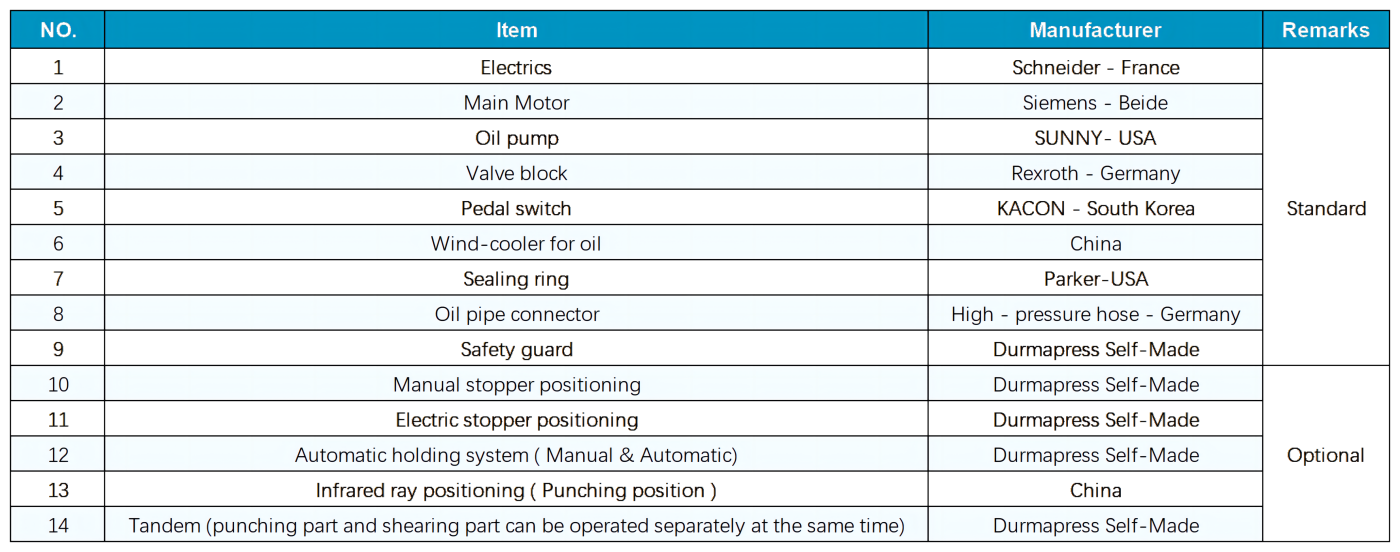

Componente estándar y opcional

Personalice su configuración según sus necesidades

Características estándar

- Un juego de punzón y matriz (agujero redondo)

- Un juego de cuchillas angulares de acero

- Un juego de cuchilla de barra cuadrada y redonda

- Un juego de cuchillas de cizalla

- Un juego de cuchillas de entallar

- 2 vástagos de pistón hidráulico y pedal independientes permiten que dos personas operen al mismo tiempo

- Funciones de control de carrera del vástago más eficaces

- Sistema de lubricación central

- Dispositivos de iluminación para el trabajo

- Tope trasero motorizado

- 5 puestos de trabajo independientes

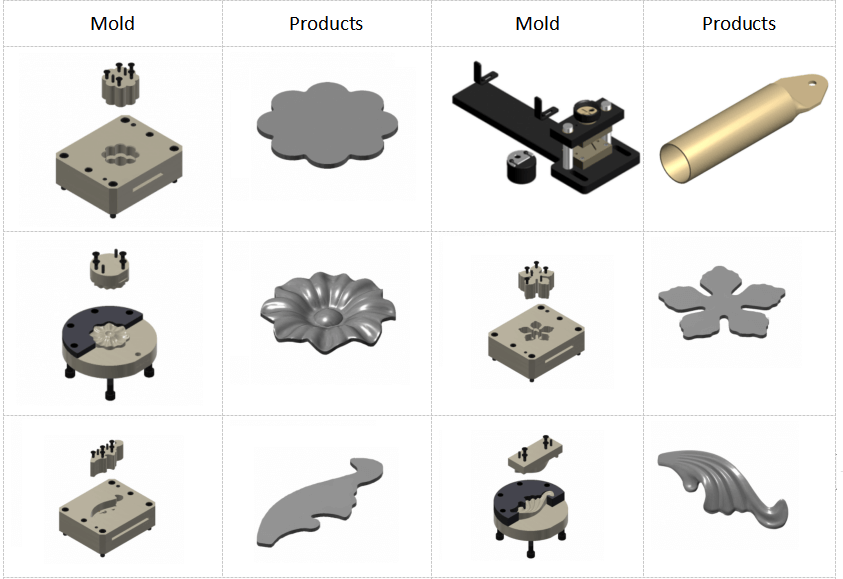

Características opcionales

- Varias herramientas para distintos fines

- Punzones y matrices cuadrados, ovalados y de rejilla

- Cizallamiento de canal y cizallamiento de viga en I

- Mesa transportadora

- Mesa de trabajo más larga

- Mesa de trabajo con guía lineal

- Φ20, 32, 60mm círculo tipo U

Componente estándar

Componente principal

resumen del marco

El bastidor de una siderúrgica hidráulica ofrece estabilidad, durabilidad y soporte para sus diversos componentes. Su diseño permite versatilidad, permitiendo a la máquina realizar múltiples funciones. El bastidor mejora la seguridad al proporcionar una plataforma estable para los operadores y está optimizado para la eficiencia, facilitando un flujo de trabajo más rápido.

Estación angular

Esta estación ofrece una gran capacidad de corte en ángulo tanto a 90° como a 45°. Para ángulos entre 45° y 90°, el proceso implica primero cortar a 90° y luego recortar la brida al ángulo deseado en la estación de cizallado.

Estación de esquila

La unidad de cizallado cuenta con una robusta sujeción que puede ajustarse para acomodar materiales de diversos grosores dentro de la capacidad de corte de la máquina. Una mesa de alimentación de cizalla ajustable con guías garantiza una alimentación precisa del material. Las guías pueden ajustarse para permitir el corte a inglete de hasta 45° para barras planas o para recortar bridas angulares.

Estación de perforación

La zona de la bancada de punzonado es espaciosa y cuenta con un bloque frontal extraíble, ideal para una amplia gama de aplicaciones de punzonado. La máquina estándar incluye una mesa de punzonado con reglas y guías para trabajos repetitivos.

Corte de canales

El corte en canal ofrece opciones personalizables para crear orificios redondos o cuadrados de varios tamaños, cumpliendo los requisitos específicos del cliente. Comparte la misma posición de trabajo para las funciones de corte redondo y cuadrado, lo que proporciona versatilidad en diversas aplicaciones.

Estación de corte

El ángulo de acero, canal de acero, acero plano, barra redonda y barra cuadrada pueden ser cortados por esta máquina, los clientes deben elegir el modelo de máquina correspondiente para cortar sus productos varisized.

Panel de control de pie

Permite un manejo cómodo y manos libres, permitiendo al operario mantener ambas manos en la pieza de trabajo para un mejor control y seguridad. Además, el panel de control de pie mejora la eficiencia al permitir al operario activar la máquina de forma rápida y sencilla mientras coloca los materiales, lo que reduce el tiempo de inactividad entre operaciones.

Piezas eléctricas

Los componentes eléctricos contribuyen a la seguridad de la máquina incorporando funciones como botones de parada de emergencia y protección contra sobrecargas. Los componentes eléctricos también mejoran la eficiencia de la máquina, permitiéndole realizar tareas con rapidez y eficacia.

Pida presupuesto ahora

Obtenga más información sobre la servoprensa de nivel superior DP-Hybrid de DURMAPRESS®.

Principales ventajas

Sierra hidráulica

La siderúrgica hidráulica es una máquina versátil con transmisión hidráulica que ofrece múltiples funciones, como corte, punzonado y plegado de diversas formas de acero. Está diseñada para un funcionamiento sencillo, un bajo consumo de energía y un mantenimiento mínimo.

La estructura incluye

- Estación de perforación

- Estación de corte de secciones

- Estación de corte en ángulo

- Estación de esquila

- Estación de entallado

fábrica de durmapree

Ver el vídeo

Fabricante de equipos punteros de tratamiento de metales

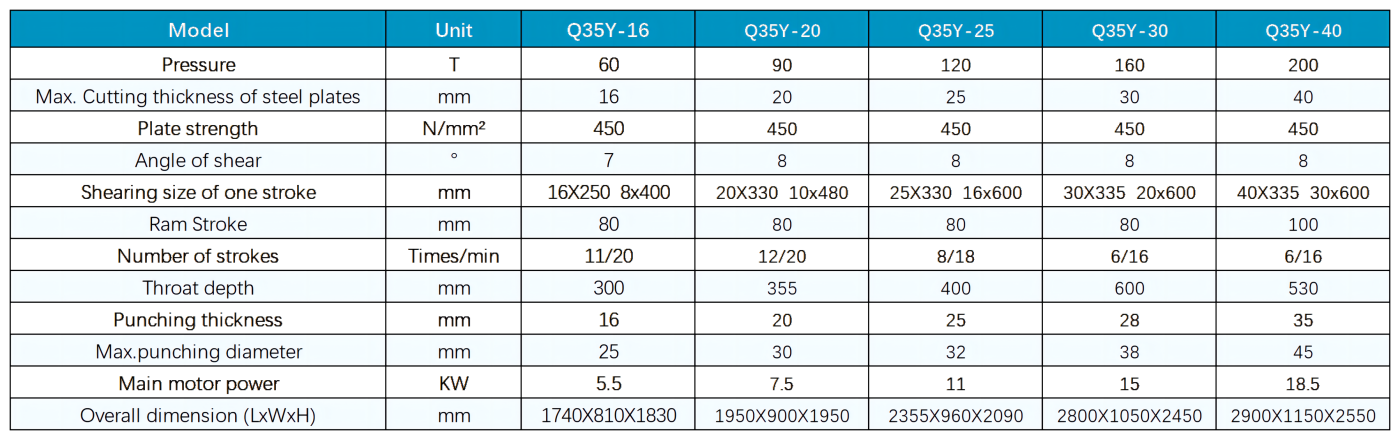

Datos técnicos

Componentes principales

Herramientas opcionales

Datos técnicos

Componentes principales

Herramientas opcionales

Póngase en contacto con nosotros

Ubicación

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Póngase en contacto con nosotros

Teléfono : + 86 183 2557 2889

Correo electrónico : [email protected]

Nuestro horario

7/24

Síguenos