features

- Using Abel's CNC system, our products are mature and reliable.

- Original electrical components from French Schneider ensure circuit longevity and stability.

- Taiwan Yuken’s hydraulic control system automates pressing and releasing with stable and reliable pressure.

- Servo motor feeds with high precision and reliability, up to 0.01mm.

- Servo motor controls both the tool post and feeding device for accurate planing and positioning.

- Touch screen enables quick and clear command input.

- Upgraded to imported alloy steel rack and pinion transmission for lower noise, easier maintenance, fewer failures, and more stable operation.

- Automatic spray cooling extends cutter life.

durmapress

Standard and optional accessories

Customize your configuration according to your needs

Standard Features

- CNC system

- Hydraulic system

- Frequency converter

- Servo motor

- Seal ring

- Motor

- Air switch

- Contactor

- Breaker and button

- Relay

- Blades

- Linear guide

- Wire

optional Features

- Blade with different material for cutting mild steel, brass, aluminum etc.

durmapress

Description of Main Components

Standard accessories for V Groover Machine

Servo Motor

Drive systems can be combined with motion control solutions provided by automation control software. Drive system is more suitable for highly dynamic multi-axis motion drive.

Machine Body

The fuselage is clamped once in steel after welding and processed by the CNC pentahedron machining center as a whole. The internal stress is eliminated by heat treatment and annealing to ensure extremely high rigidity and machining accuracy.

Blade

The tool holder uses a servo motor, which has a large moving torque, fast acceleration and deceleration, accurate positioning and high efficiency.

Schneider Electrical

Using Schneider electrical components in CNC V Grooving Machines guarantees a high level of performance, safety, and reliability, making it a preferred choice for manufacturers seeking superior quality and efficiency.

Pida presupuesto ahora

Contact us to learn more about Hydraulic Rolling Machine

Why choose us

from start to finish

Durmapress always adheres to the concept of putting customers first in the whole purchase experience, and continuously optimizes and innovates the production process to cater to the needs of all large, medium and small manufacturing companies.

- Más de 20 años de experiencia

- Personalized customized machines

- Perfect after-sales system

- 24/7 Availability

Get more details

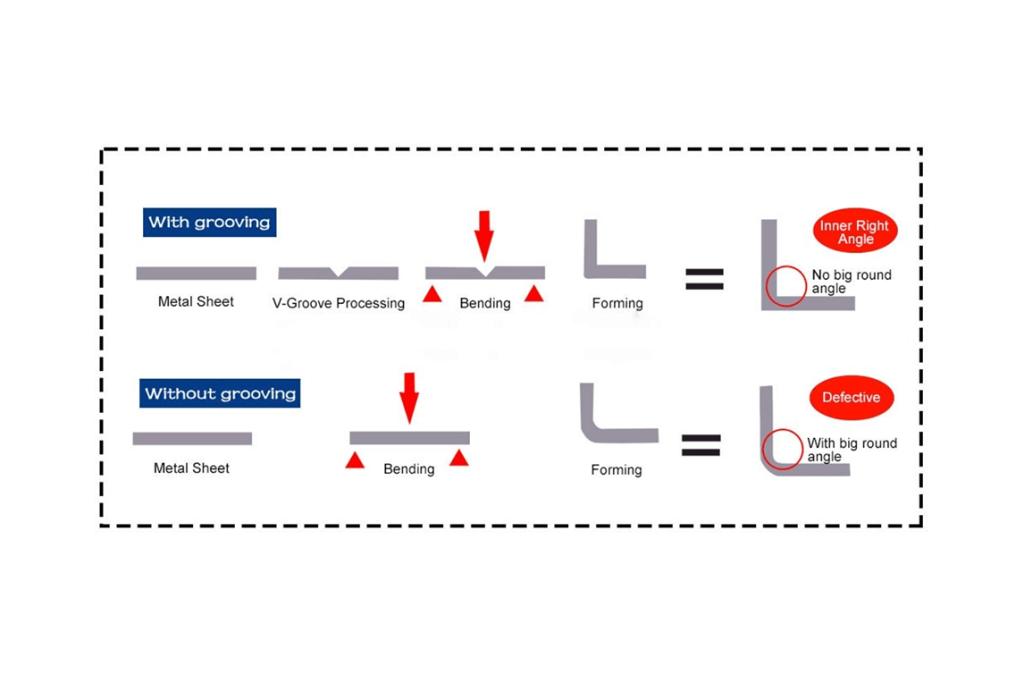

Why To Choose CNC V Grooving Machine?

1

High Precision and Accuracy

CNC V Grooving Machines are known for their exceptional precision, ensuring accurate grooves and cuts. The computer-controlled system allows for exact measurements and consistent results, minimizing errors and material waste.

2

Versatility

These machines can handle a wide range of materials, including stainless steel, aluminum, copper, and other metals. They are versatile enough to be used in various industries such as aerospace, automotive, architecture, and electronics.

3

Increased Efficiency

CNC technology automates the grooving process, significantly reducing manual labor and increasing productivity. The machines can operate continuously with minimal supervision, leading to faster turnaround times and higher output.

4

Reduced Material Waste

The precision of CNC V Grooving Machines means that material waste is minimized. The exact cutting and grooving reduce the likelihood of errors that could lead to costly rework or material loss.

5

Improved Safety

CNC machines are designed with safety features that protect operators from potential hazards. Automated processes reduce the need for manual handling of materials, lowering the risk of accidents and injuries.

6

Complex and Intricate Designs

With CNC V Grooving Machines, creating complex and intricate designs becomes much easier. The advanced software allows for detailed programming, enabling the production of sophisticated patterns and shapes that would be difficult to achieve manually.

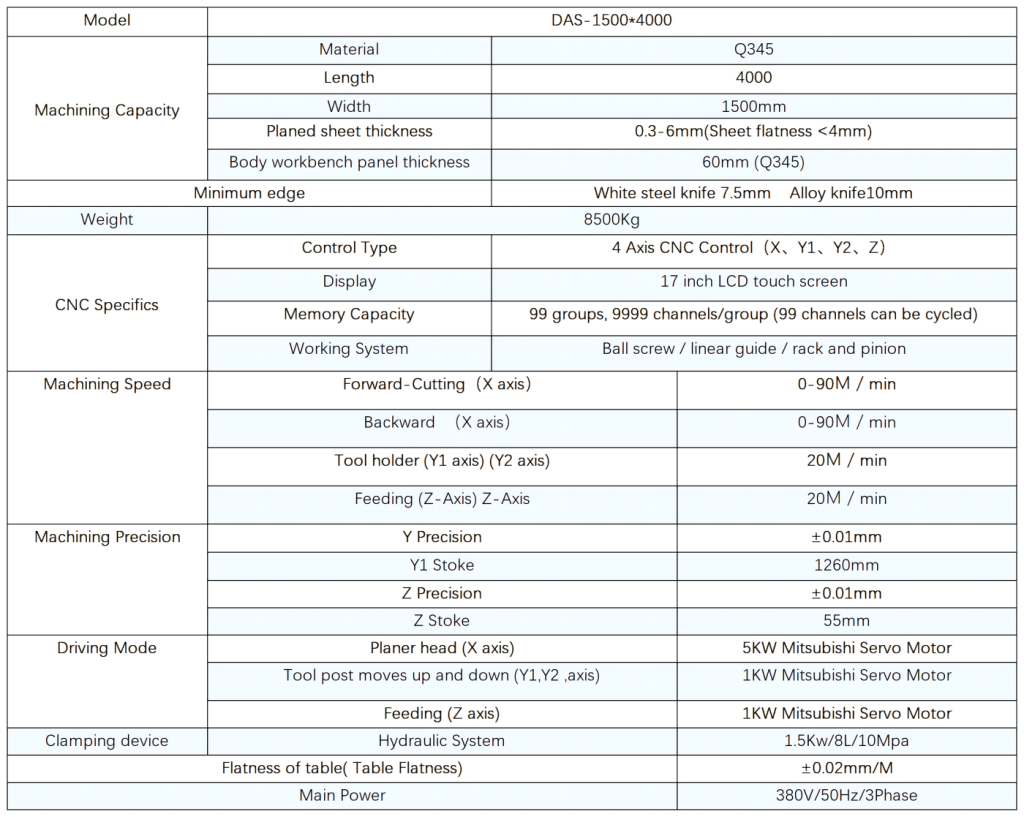

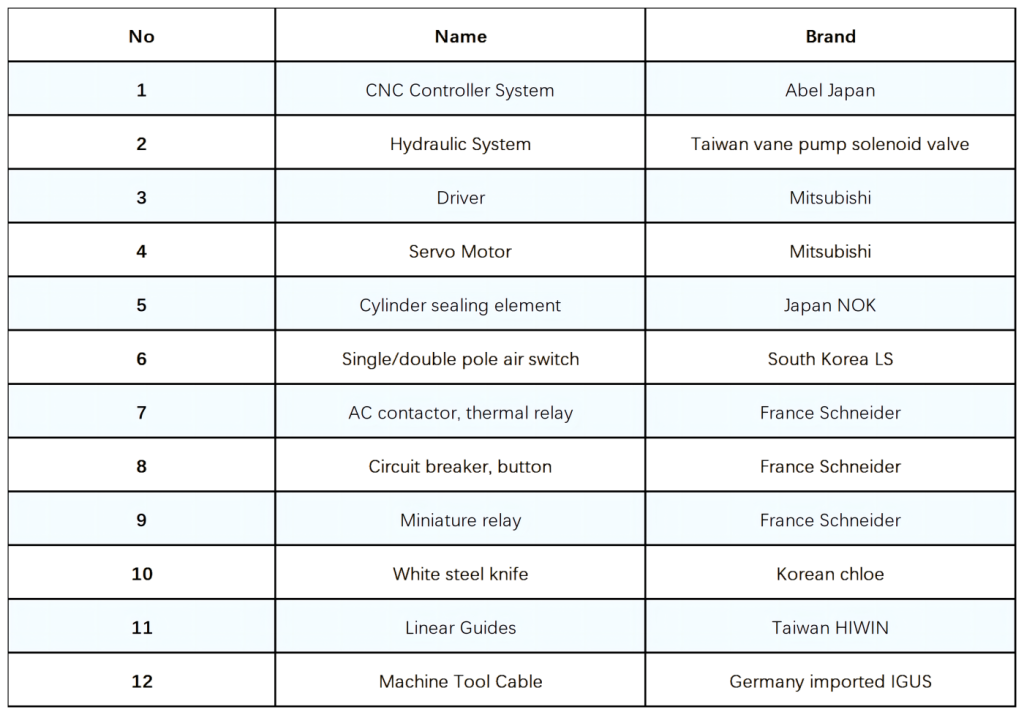

Technical Data

Main Components

Technical Data

Main Components

fábrica de durmapress

Watch the Video

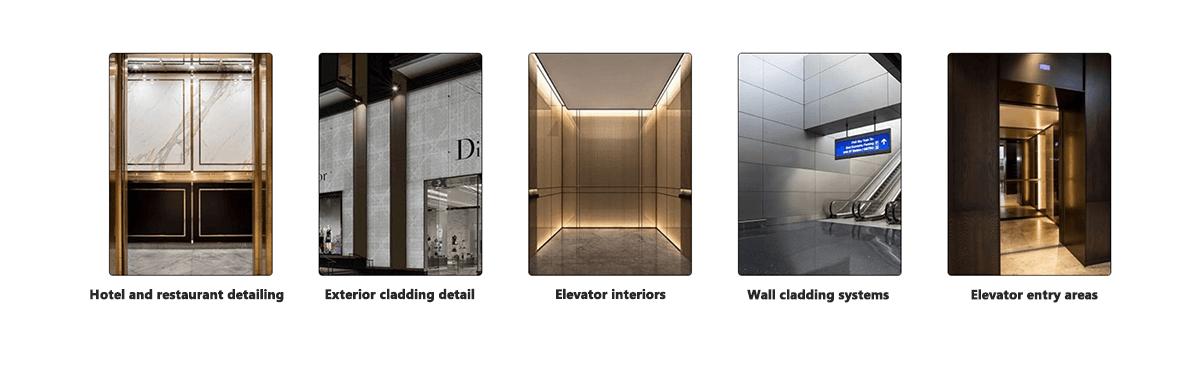

applications

Póngase en contacto con nosotros

Ubicación

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Póngase en contacto con nosotros

Teléfono : + 86 183 2557 2889

Correo electrónico : [email protected]

Nuestro horario

7/24

Síguenos