Sheet and Tube Laser Cutter -Full Covered

General Características

BS3015E series Sheet and tube laser cutter is designed for customers who need both sheet cutting and tube cutting. The tube-sheet integrated fiber laser cutting equipment (tube-sheet dual-purpose laser cutting machine | tube-sheet dual-purpose metal fiber laser cutting machine | tube laser Cutting Machine). It has the advantages of stable performance, high efficiency and energy saving, and high cost performance. YC-GQ3015-G specializes in cutting square pipes, round pipes, rectangular pipes, D-shaped pipes and hexagonal pipes and other types of pipes, square pipe □20*20-□100*100mm, round pipe Φ20-Φ150mm, pipe wall thickness 0.5-5mm carbon steel pipe, 0.5-3mm stainless steel pipe; cutting 0.5~12mm carbon steel plate, 0.5~5mm stainless steel plate, 0.5~3mm brass, 0.5~2mm copper and galvanized sheet, electrolytic plate, silicon steel and other metal materials ( The thickness and material are related to the laser)

Why Choose BS3015E

1. Sheet and tube laser cutter can cut multiple cylindrical intersecting holes of different directions and different diameters on the main pipe to meet the conditions of eccentric and non-eccentric perpendicular intersection between the branch pipe axis and the main pipe axis.

2. It can cut the end of the cylindrical intersecting line at the end of the branch pipe to meet the conditions of eccentric and non-eccentric perpendicular intersection and oblique intersection between the branch pipe axis and the main pipe axis.

3. Ability to cut the oblique end face at the end of the round pipe.

4. It can cut and weld the elbow on the round pipe, and the two ends of the "shrimp joint" can be obliquely cut off.

5. It can cut the end of the branch pipe intersecting line that intersects with the ring main pipe.

6. It can cut variable angle bevel surface.

7. It can cut square holes and waist-shaped holes on round pipes.

8. It can cut steel pipes.

9. Various graphics on the surface of the square tube.

Application field

★It can cut metal, various non-metallic sheets and pipes. It is especially suitable for cutting stainless steel, iron, aluminum, copper, titanium steel, ceramic wafers, silicon wafers, diamonds and other materials.

★Widely used in sheet metal, hardware, steel structure, precision machinery, auto parts, glasses, jewelry, nameplates, advertising, handicrafts, electronics, toys, packaging and other industries.

Cortador de luz 2.0

Ya sea para corte plano o en ángulo:

The LightCutter cutting head is the ideal solution for efficient and economical Sheet and tube laser cutter in the medium power range up to 6 kW. The cutting optics are characterized by a high cut quality for all metals up to 16 mm thick – in particular structural steel, stainless steel and aluminum.

Fuente láser IPG

| 1000W – 4 kW average power range |

| Eficacia récord del enchufe de pared |

| Excelente fiabilidad |

| Excelente calidad del haz monomodo |

| Apuntamiento insignificante del haz |

| Calidad estable del haz en toda la gama de potencia |

| Modulación directa en la gama de kHz |

| Muy bajo coste |

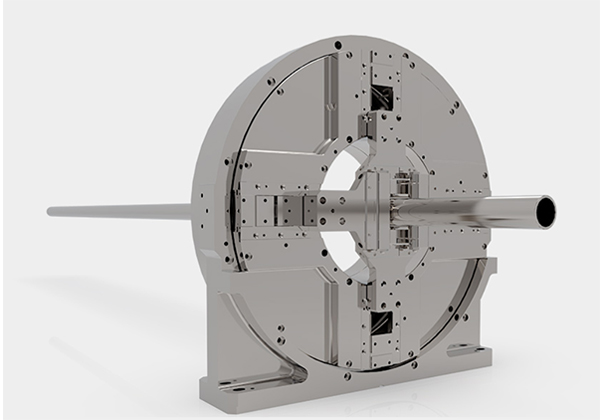

Mandril automático

1. The characteristics of the electric chuck are: fast speed, high precision and long life.

2. Through the switch on the electric control box, the clamping and unclamping of the power chuck driven by the motor can be realized, and the forward and reverse rotation of the motor can be controlled. Adjust the voltage adjustment knob on the electric control box to adjust the drive voltage. Changing the output torque of the motor and adjusting the clamping force of the chuck make it more convenient to use.

Yaskawa Reducer

Tiene las características de economía y practicidad, alto rendimiento de costes, alta precisión, buena rigidez, gran capacidad de carga, alta eficiencia, larga vida útil, ligero y de pequeño tamaño, aspecto hermoso, instalación conveniente, posicionamiento preciso y así sucesivamente. Adecuado para servomotores de CA, servomotores de CC, motores paso a paso, motores hidráulicos para aumentar y disminuir la velocidad de transmisión. Adecuado para la conexión de productos de accionamiento fabricados por cualquier fabricante del mundo.

En la aplicación de servo control, ejerce un buen efecto de rigidez servo, control de posicionamiento preciso, y tiene las características de juego bajo y medio, alta eficiencia, alta velocidad de entrada, alto par de entrada, operación suave y bajo ruido en la plataforma de operación. Pequeña apariencia y diseño de la estructura

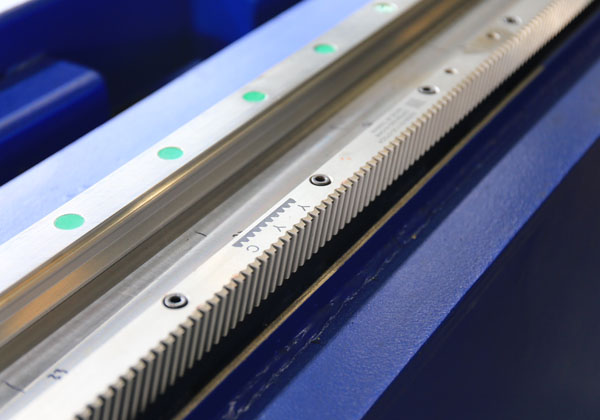

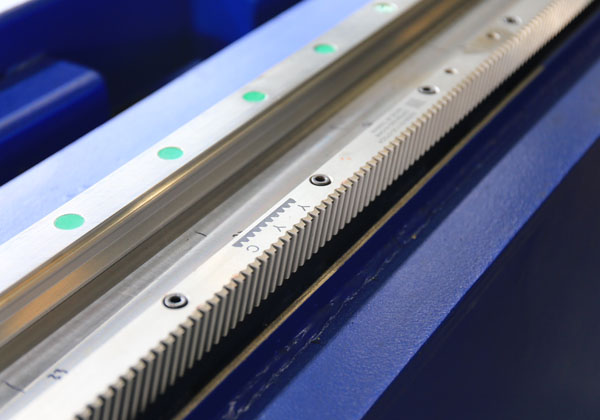

Equipo YYC de Taiwán

Para satisfacer las necesidades de los equipos mecánicos, YYC proporciona cremalleras y piñones con diferentes módulos, que pueden sustituir completamente a productos de transmisión lineal como husillos de bolas, cilindros y motores lineales, y tienen un excelente rendimiento de costes.

Sheet and tube laser cutter tube Axis

1. High cutting precision, smooth and clean cutting, no burrs, and low material loss;

2. The heat-affected zone of laser cutting is very small, and there is almost no thermal deformation.

3. Mass production, high efficiency cutting. The standard pipe length is 6 meters. Traditional processing methods require very large fixtures. Laser processing can easily complete the positioning of several meters of pipe clamps, which makes batch processing possible.

The Sheet and tube laser cutter is controlled by a digital system, which is one of the advantages of the laser cutting machine for cutting pipes. Laser cutting tube technology can handle any programmed shape and cut in any direction. It can realize a variety of cutting processes for complex tube structures, such as cutting, chamfering, grooving or perforating, scoring, etc.

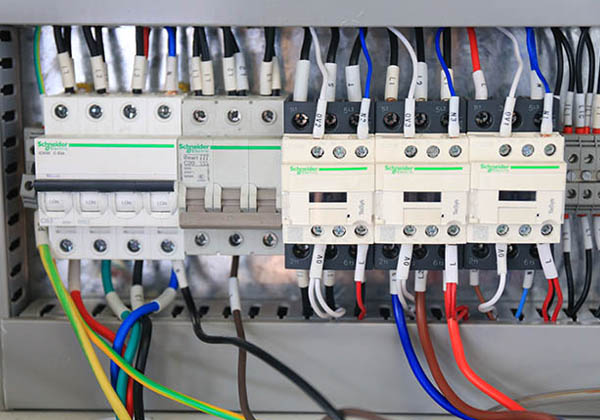

OTROS COMPONENTES

DATOS TÉCNICOS

| No. | Tipo | BS3015E | BS4020E | BS6025E | ||

|---|---|---|---|---|---|---|

| 1 | Área de mecanizado (Longitud *anchura) | 3000*1500mm | 4000*2000mm | 6000*2500mm | ||

| 2 | Recorrido del eje X | 1525 mm | 4020mm | 6050mm | ||

| 3 | Recorrido del eje Y | 3005 mm | 2020mm | 2550 mm | ||

| 4 | Recorrido del eje Z | 150 mm | 120 mm | 250mm | ||

| 5 | Precisión de posicionamiento del eje X/Y | ±0,02 mm/m | ±0,03 mm/m | ±0,03 mm/m | ||

| 6 | Precisión de posicionamiento repetitivo del eje X/Y | ±0,02 mm | ±0,02 mm | ±0,02 mm | ||

| 7 | Velocidad máxima | 140 m/min | 140 m/min | 120 m/min | ||

| 8 | Velocidad máxima de aceleración | 1.5G | 1.5G | 1.5G | ||

| 9 | Peso de la herramienta | 9800KGS | 7500KGS | 10000KGS | ||

| 10 | Carga máxima del banco de trabajo | 1000KGS | 2500KGS | 7000KGS | ||

| 11 | Potencia láser | 2000W/3000/4000W/6000W | ||||

| 12 | Dimensión ( Longitud * Anchura * Altura) | 9800*2350*2000 | 11500mm*3500mm*2500mm | 15900*3400*2100mm | ||

| 13 | Número de fases | 3 | 3 | 3 | ||

| 14 | Tensión nominal de la fuente de alimentación | 380V | 380V | 380V | ||

| 15 | Frecuencia | 50 HZ | 50 HZ | 50 HZ | ||

| 16 | Grado de protección de la alimentación principal | IP54 | IP54 | IP54 | ||

| 17 | Tube Diameter & Length | 220mm*6000mm length | 220mm*6000mm length | 220mm*6000mm length | ||