Fiber Laser Cutting Machine -Open Type

General Características

Focus on carbon steel within 20mm, high-efficiency cutting of stainless steel, galvanized sheet, electrolytic board, silicon steel and other metal materials within 10mm.

- It is widely used in kitchen appliances, lighting hardware, cabinet, advertising signs, display equipment and sheet metal processing industries etc.

- Adopting floorstanding gantry dual-drives structure, which is compact and covers small area. It is easy for operation, maintenance and metal sheet handling

- Machine body is processed through plug welding and annealing, with aluminum beams to meet long-term high acceleration requirement.

- Equipping with imported servo unit from Japan and Germany reducer to ensure the accuracy of lasting stability

- Adopt high-performance fiber laser generator and features high photoelectric conversion efficiency, fast cutting speed, maintenance-free, low cost, and high stability

Why Choose BS3015D

BS3015D is a perfect standard plane fiber laser cutting machine, which is popular in the industry. It has the highest speedamong those with the same level and may cut 400 small circles per minute. With the maximum speed of 140m and maximumacceleration of 1.2G, it has the highest accuracy among those with the same leve and may cut the bicycle with the size of 1/5 of coin.

¿Desea recibir el folleto?

Fuente láser

JPT single mode fiber laser(500W-2000W) is the optimal combination of optical, mechanical, electrical and software components. Through the controlling ports and the controlling software, the operating status of the laser can be monitored in real time, alarm messages can be received in time, and data can be collected. The laser uses water-cooling and shelf case design, with competitive advantage like high energy conversion (electric to light), low power consumption, maintenance free, fiber delivery, and easy to assemble, it is the most suitable laser source for industrial laser welding, cutting and other applications.

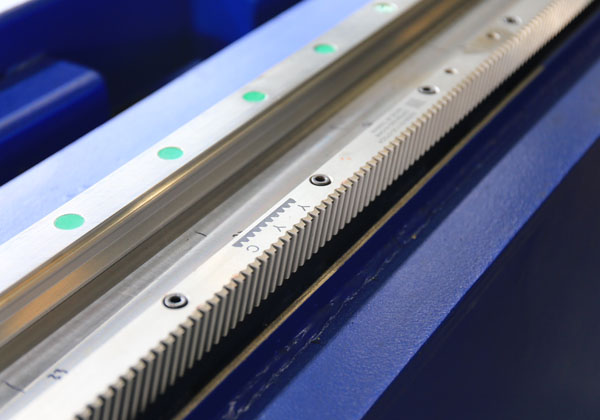

Estación de esquila

Estación de perforación

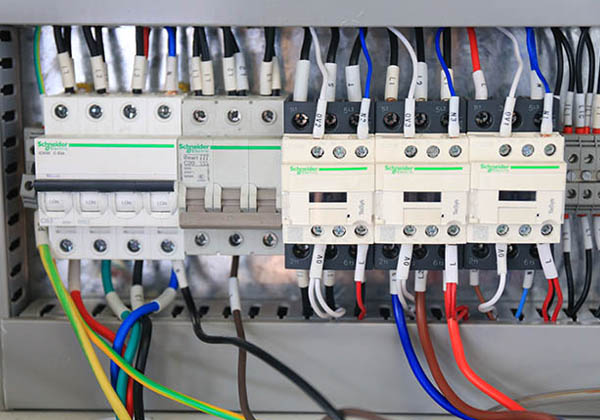

OTROS COMPONENTES

DATOS TÉCNICOS

| No. | Tipo | BS3015D | BS4020D | BS6020D | BS6025D | |||

|---|---|---|---|---|---|---|---|---|

| 1 | Área de mecanizado (Longitud *anchura) | 3000*1500mm | 4000*2000mm | 6000*2000mm | 6000*2500mm | |||

| 2 | Recorrido del eje X | 1525 mm | 4020mm | 2020mm | 6020mm | |||

| 3 | Recorrido del eje Y | 3005 mm | 2020mm | 250mm | 2520mm | |||

| 4 | Recorrido del eje Z | 150 mm | 150 mm | 150 mm | 150 mm | |||

| 5 | Precisión de posicionamiento del eje X/Y | ±0,02 mm/m | ±0,03 mm/m | ±0,03 mm/m | ±0,03 mm/m | |||

| 6 | Precisión de posicionamiento repetitivo del eje X/Y | ±0,02 mm | ±0,02 mm | ±0,02 mm | ±0,02 mm | |||

| 7 | Velocidad máxima | 140 m/min | 100 m/min | 120 m/min | 100 m/min | |||

| 8 | Velocidad máxima de aceleración | 1.5G | 1.5G | 1.5G | 1.5G | |||

| 9 | Peso de la herramienta | 5500KGS | 6500KGS | 7500KGS | 7900KGS | |||

| 10 | Carga máxima del banco de trabajo | 1000KGS | 1500KGS | 1800KGS | 2000KGS | |||

| 11 | Potencia láser | 1000W/1500W/2000W | ||||||

| 12 | Dimensión ( Longitud * Anchura * Altura) | 4500*2350*2000mm | 6100*3500*1600mm | 8200*3200*2000mm | 6100*4200*1600mm | |||

| 13 | Número de fases | 3 | 3 | 3 | 3 | |||

| 14 | Tensión nominal de la fuente de alimentación | 380V | 380V | 380V | 380V | |||

| 15 | Frecuencia | 50 HZ | 50 HZ | 50 HZ | 50 HZ | |||

| 16 | Grado de protección de la alimentación principal | IP54 | IP54 | IP54 | IP54 | |||