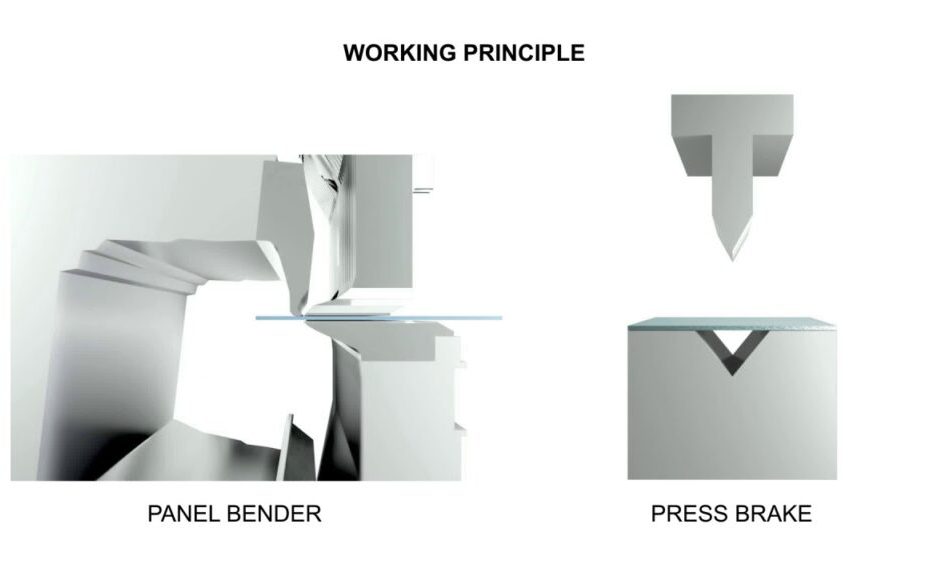

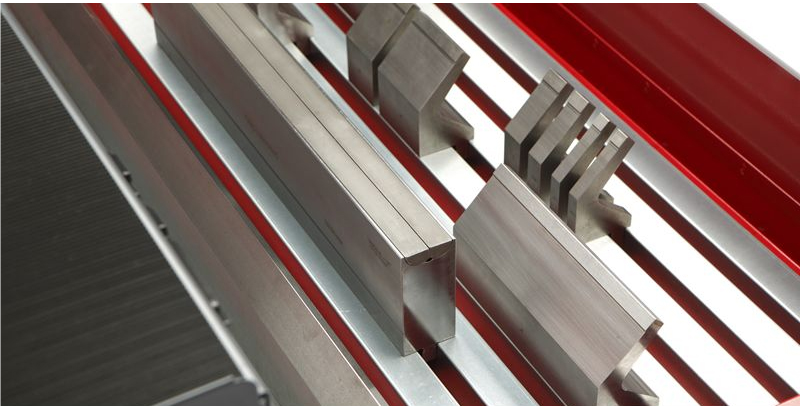

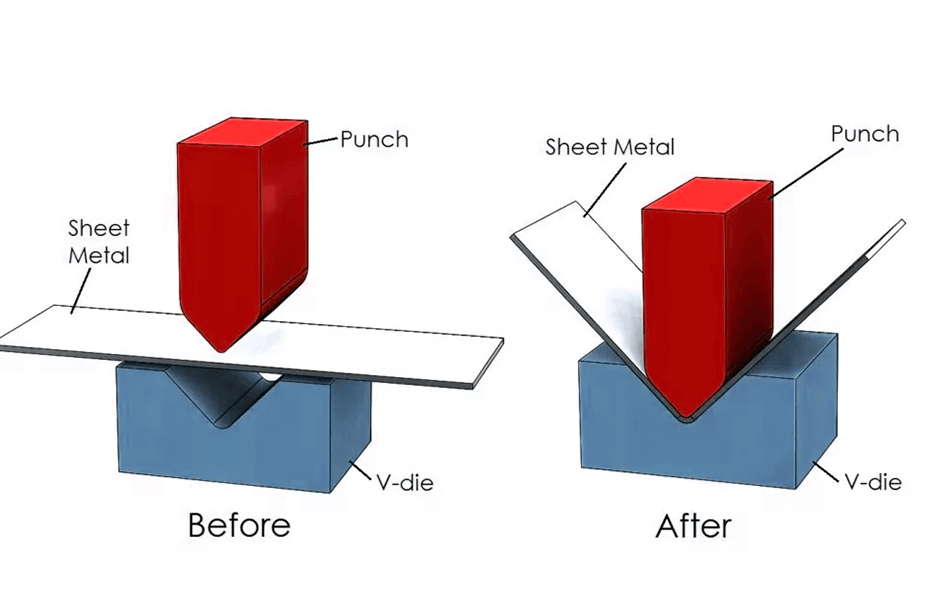

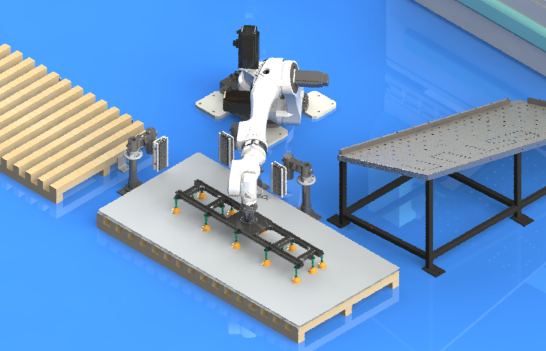

This article discusses two common metal fabrication machines, the Press Brake and the Panel Bender, comparing their pros and cons to help readers choose the machine that best suits their needs. Firstly, it introduces the Press Brake, which is suitable for processing metal sheets of various thicknesses and materials, capable of intricate bending work. Next, the article discusses the Panel Bender, which is efficient in handling large panels and can automatically adjust workflows to enhance production efficiency. Lastly, the article summarizes the differences between the two, including their applications, costs, and maintenance requirements, to enable readers to make informed decisions when choosing between the two machines.