Electric CNC steel tube bending machine hydraulic square tube bending machine performance characteristics:

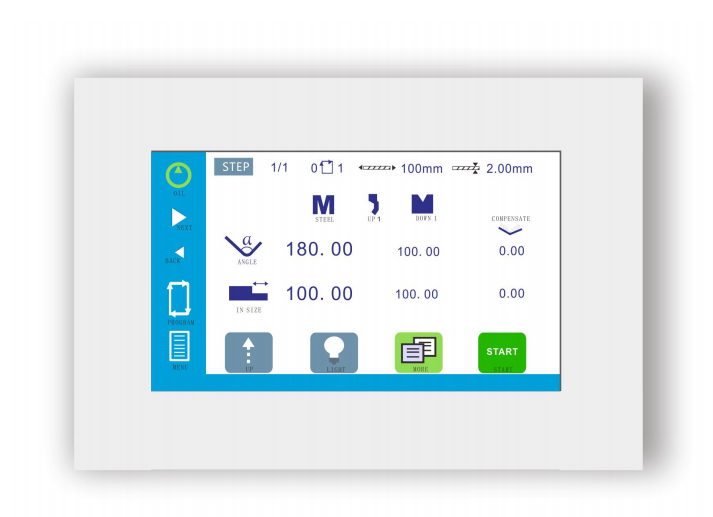

Electric CNC steel tube bending machine hydraulic square tube bending machine performance characteristics: 1.This machine adopts PLC control, dialogue operation, simple and easy program setting. 2, can freely choose, manual, semi-automatic half-cycle, full automatic cycle function. 3, mobile foot switch, with automatic start, emergency stop, stop to continue three functions, high safety. 4, large capacity cooling circulation system, make the machine run more stable. 5. The head and elbow are exquisitely designed to provide maximum elbow space. 6, touch simple… Leer Más "Electric CNC steel tube bending machine hydraulic square tube bending machine performance characteristics: