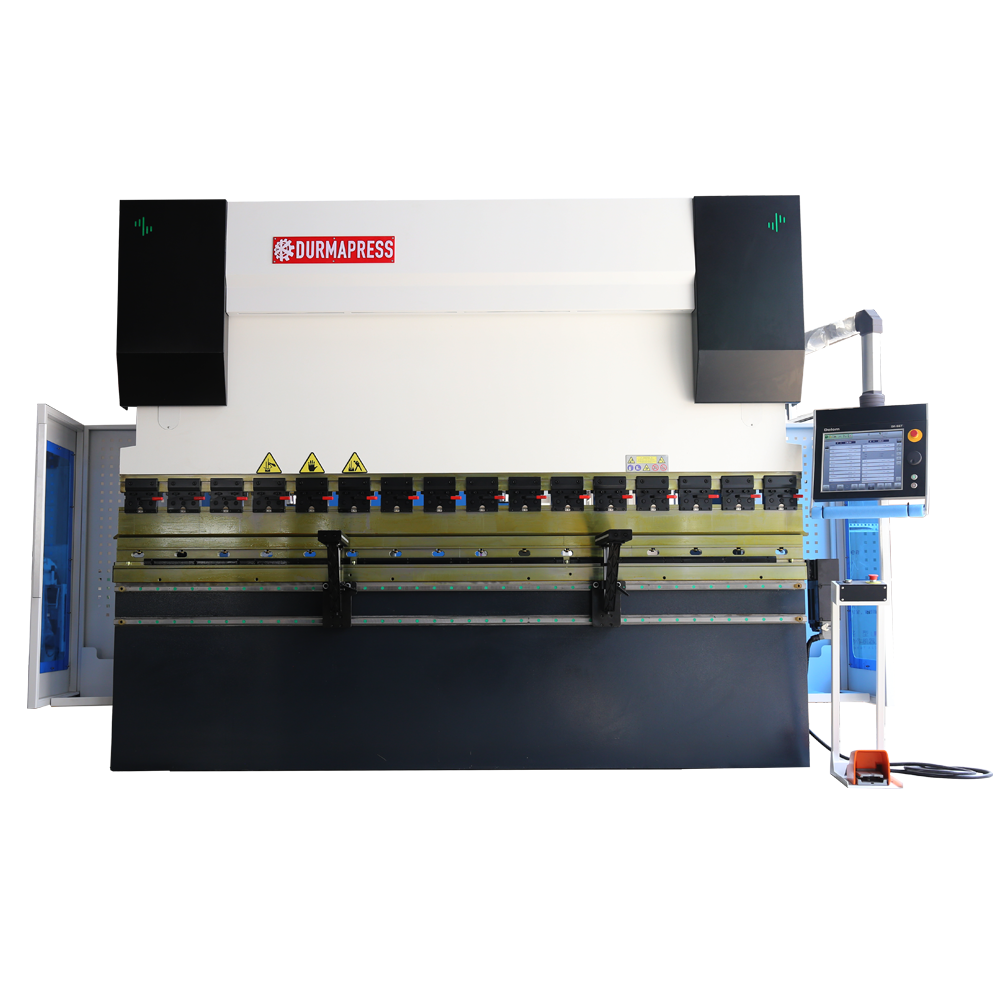

CNC Press Brake DA66T

General Características

DA66T electro-hydraulic CNC Press Brake Machine

- Sturdy steel plate welded structure, vibration relieve stress

- Stable and reliable upper transmission

- Outstanding eccentric load function, the sheet is allowed to bend at any point of the lower die, not necessarily in the middle

- Electro-hydraulic proportional servo synchronization to ensure the accuracy of repeated operations

- It can be controlled at any point within the stroke, with repeatability up to +/-0.01 and parallelism up to 0.02

- Lower worktable adopts deflection compensation or upper die is equipped with deflection compensation mechanism

- Equipped with Dutch Delem DA66T CNC system, grating ruler, Rexroth hydraulic system valve group, servo motor, and other well-known brand accessories, with good performance

Controlador CNC DA66T From Delem

Datos del controlador

- Modo de programación con pantalla táctil gráfica 2D

- Visualización 3D en simulación y producción

- 17″ high resolution colour TFT

- Paquete completo de aplicaciones Windows

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, interfaz de periféricos

- User specific application support within the controllers multitasking environment

- Interfaz de flexión y corrección del sensor

- Profile-TL offline software

Inquiry Now For Agent Price

Bastidor de la máquina

The DA66T electro-hydraulic CNC Press Brake machine model is MB8 Series CNC Press Brake with a solid steel plate welded structure, vibration-relief stress; outstanding eccentric load function, sheet metal is allowed to bend at any point of the lower die, It does not have to be in the middle; the electronic hydraulic proportional servo is synchronized to ensure the accuracy of repeated operations; it can be controlled at any point within the stroke, with a repeatability of +/-0.01 and a parallelism of 0.02.

Utillaje para prensas plegadoras

The standard top punch and dual-V bottom die are specially designed for bending sheet metals. More press brake toolings can be selected as per your practical use. Material and HRC47 degree values are marked on it

Back Guage

Utilizamos el husillo de bolas PMI de Taiwán y la guía lineal para asegurar el movimiento del eje X con mayor precisión que el uso de la varilla. Y el tope trasero adopta un mecanismo de correa dentada y rueda controlado por un servomotor en lugar de un motor paso a paso. La altura del dedo del tope trasero se puede ajustar manualmente. En total hay TRES piezas de dedos para posicionamiento.

OTROS COMPONENTES

DATOS TÉCNICOS

| Seri-al NO. | Nombre | Numerical Value | Unidad | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40T/2500 | 63T/2500 | 63T/3200 | 63T/4000 | 80T/2500 | 80T/3200 | 80T/4000 | 100T/2500 | 100T/3200 | 100T/4000 | 125T/3200 | 125T/4000 | 160T/3200 | 160T/4000 | 200T/3200 | 200T/4000 | 250T/3200 | 250T/4000 | 300T/3200 | 300T/4000 | 300T/6000 | 400T/3200 | 400T/4000 | 400T/6000 | 500T/6000 | 600T/6000 | |||||||||||||||||||||||||||||||

| 1 | CNC Control Axis | 3+1 axis ( Y1, Y2, X + V Crowning ) Optional R axis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | Nominal force | 4000 | 630 | 630 | 630 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1250 | 1250 | 1600 | 1600 | 2000 | 2000 | 2500 | 2500 | 3000 | 3000 | 3000 | 4000 | 4000 | 4000 | 5000 | 6000 | KN | ||||||||||||||||||||||||||||

| 3 | Bending length | 2500 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 6000 | 3200 | 4000 | 6000 | 6000 | 6000 | mm | ||||||||||||||||||||||||||||

| 4 | Slider Stroke | 150 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 250 | 250 | 200 | 200 | 250 | 320 | 320 | 320 | 320 | 320 | mm | ||||||||||||||||||||||||||||

| 5 | Daylight | 430 | 470 | 470 | 470 | 470 | 470 | 470 | 470 | 470 | 460 | 470 | 470 | 470 | 460 | 470 | 470 | 470 | 470 | 500 | 500 | 540 | 560 | 560 | 560 | 560 | 560 | |||||||||||||||||||||||||||||

| 6 | Profundidad de garganta | 250 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 520 | 520 | 280 | 280 | 400 | 400 | 400 | 400 | 470 | 500 | |||||||||||||||||||||||||||||

| 7 | Table width | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 160 | 160 | |||||||||||||||||||||||||||||

| 8 | Working table height | 900 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 3150 | 1000 | 1000 | 1000 | mm | ||||||||||||||||||||||||||||

| 9 | Working Speed | Full Load-speed | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 120 | 130 | 120 | 110 | 110 | 150 | 150 | 90 | 85 | 85 | 85 | 85 | 85 | Mm/sec | |||||||||||||||||||||||||||

| Work-speed | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 9 | 9 | 9 | 9 | 9 | 0-9.5 | 0-9.5 | 9 | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 | ||||||||||||||||||||||||||||||

| High-return speed | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 95 | 95 | 95 | 95 | 95 | 110 | 110 | 100 | 85 | 85 | 85 | 75 | 85 | ||||||||||||||||||||||||||||||

| 10 | CNC Backguage | Max Travel X- Axis | 400 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 500 | 500 | 800 | 550 | 550 | 550 | 550 | 550 | MM | |||||||||||||||||||||||||||

| Max Travel R- Axis | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 150 | 150 | 200 | 150 | 150 | 150 | 150 | 150 | MM | |||||||||||||||||||||||||||||

| Finger Block | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 6 | 6 | 6 | PC | |||||||||||||||||||||||||||||

| 11 | Capacity | Hydraulic pressure | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | Bar | |||||||||||||||||||||||||||

| Potencia del motor | 5.5 | 5.5 | 7.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 15 | 15 | 18.5 | 18.5 | 22 | 22 | 22 | 30 | 30 | 30 | 37 | 45 | Kw | |||||||||||||||||||||||||||||

| Oil Tank Capacity | 200 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Lts | |||||||||||||||||||||||||||||

| 12 | Machine weight | 2300 | 4800 | 5400 | 6200 | 5800 | 6300 | 7800 | 8500 | 8500 | 9600 | 8800 | 9800 | 10200 | 10500 | 14000 | 15000 | 15500 | 16500 | 16800 | 17800 | 24500 | 23000 | 26500 | 32500 | 40000 | 6550 | Kgs | ||||||||||||||||||||||||||||

| 13 | Overall dimension | Longitud | 2850 | 4550 | 4550 | 4550 | 2850 | 3550 | 4550 | 2850 | 3650 | 4550 | 3850 | 4550 | 3550 | 4550 | 3550 | 4360 | 4350 | 4350 | 3550 | 4550 | 6350 | 3850 | 4550 | 6550 | 6550 | 2350 | mm | |||||||||||||||||||||||||||

| Anchura | 1860 | 1950 | 1950 | 1950 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 3580 | ||||||||||||||||||||||||||||||

| Altura | 1900 | 2150 | 2150 | 2150 | 2250 | 2250 | 2250 | 2450 | 2450 | 2450 | 2480 | 2480 | 2680 | 2680 | 2880 | 2880 | 2980 | 2980 | 3180 | 3180 | 3200 | 3180 | 3180 | 3180 | 3380 | |||||||||||||||||||||||||||||||

| 14 | Requisitos de potencia | AC 220V~480V,3ph,50/60HZ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||