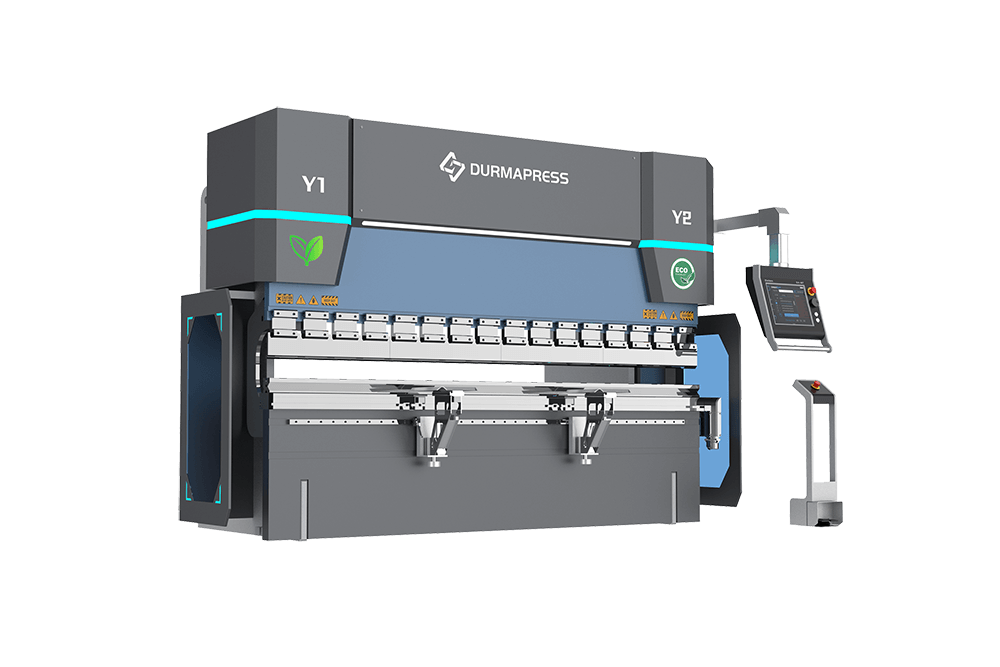

DP-Hybrid Euro series

CNC Press Brake

The DP-Hybrid Servo CNC press brake combines innovative technology with DURMAPRESS’s proven expertise. Its dynamic hybrid-servo drive and user-friendly control make it a versatile and powerful solution.

The DP-Hybrid Servo CNC press brake combines innovative technology with DURMAPRESS’s proven expertise. Its dynamic hybrid-servo drive and user-friendly control make it a versatile and powerful solution.

Utillaje para prensas plegadoras

Portaherramientas

Sistema de control CNC

Luz

Interruptor de pedal

Hoja Frente Partidario

Coronación

La serie DA-50Touch ofrece soluciones modernas, compactas y versátiles para una amplia gama de aplicaciones de plegado sin comprometer la funcionalidad de la máquina.

Customize The Controller For Your DP-Hybird Series

The DA-58TX is a modern 2D CNC control for synchronized press brakes, offering easy programming and automatic bend sequence calculation via a Delem touch screen.

The DA-66S features 2D programming with automatic bend sequence calculation, collision detection, and full 3D setup with multiple tool stations for accurate feasibility feedback.

The DA-69S is a top-of-the-line 3D CNC control, offering advanced programming, automatic bend calculation, collision detection, and full 3D setup for unmatched productivity.

Cada pieza puede garantizar una larga vida útil y reducir los costes de producción.

Las plegadoras Durmapress incorporan un robusto bastidor monobloque fabricado en acero de alto rendimiento, que garantiza una precisión y fiabilidad duraderas. Cada bastidor está templado y respaldado por una garantía de 15 años.

Ciertamente, el controlador funciona como la inteligencia central de toda la maquinaria. Nuestra empresa suministra controladores de primera calidad procedentes de marcas de prestigio como Delem, ESAy Cybelec.

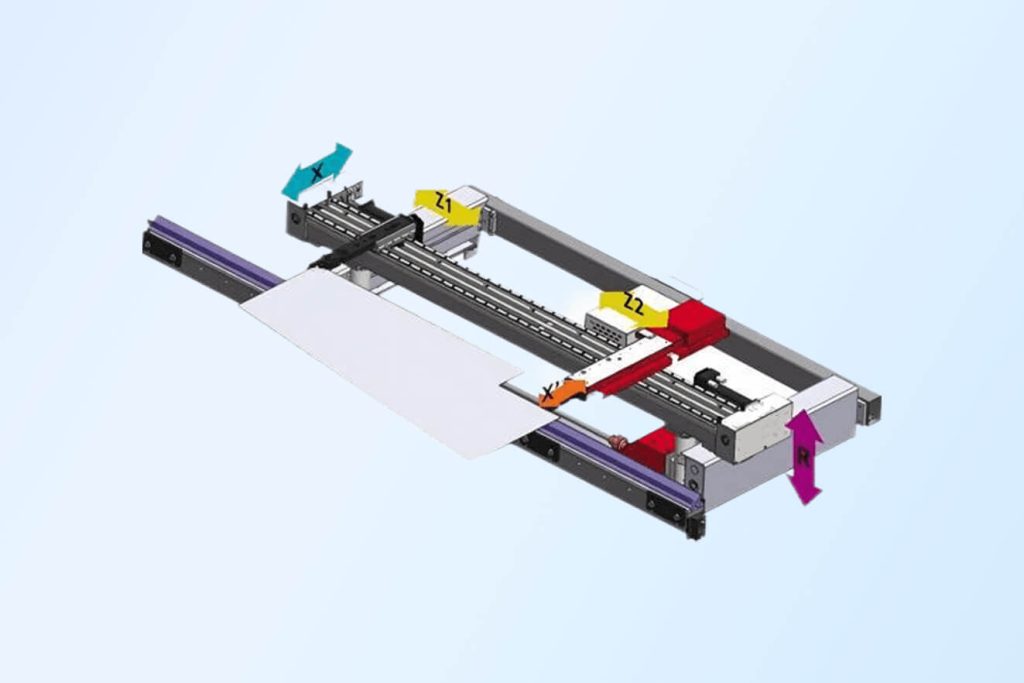

We use Taiwan PMI ball screw and linear guide for X-axis precision, ensuring higher accuracy than rod-based systems. The back gauge, controlled by a servo motor with a timing belt & wheel mechanism, offers precise positioning.

Aprovechando la fiabilidad de los componentes originales Schneider procedentes directamente de Francia, famosos por su estabilidad inquebrantable, su impresionante durabilidad y su prolongada vida útil.

It ensures consistent processing position and size by precisely controlling the workpiece stop. The adjustable Stopper Finger position and height accommodate various workpiece sizes and shapes.

The durable front supporter ensures long-lasting stability and precise positioning, reducing workpiece deformation and enhancing processing accuracy.

Accesorios de primera calidad de las principales marcas internacionales

Ensures precise, consistent bend angles across the workpiece, compensating for die deflection to reduce scrap and boost efficiency.

The European Type Sectioned 4V Die & Punch offers versatile bending, quick setup, and high precision for enhanced press brake performance.

Experimente una precisión sin igual con el sistema de medición de ángulos iMeasure Laser en colaboración con Data-M Engineering, que garantiza ángulos de curvatura exactos con una sola operación.

El sistema de protección láser DSP supervisa la intensidad y la ubicación de la radiación láser en tiempo real para garantizar que cualquier posible riesgo para la seguridad láser pueda detectarse a tiempo cuando la plegadora esté en funcionamiento.

Los últimos seguidores para el plegado de chapa pretenden optimizar las prestaciones de nuestras plegadoras reduciendo el tiempo de puesta a punto de la plegadora y simplificando el trabajo de los operarios. Estas ayudas al plegado proporcionan a los operarios una valiosa asistencia práctica.

Utilizamos las tecnologías innovadoras de WILA, incluyendo Safety-Click®, Smart Tool Locator® y el sistema de reemplazo E2M® para herramientas (de trabajo pesado), para mejorar la seguridad y conveniencia del reemplazo. La precisión y la ergonomía se adaptan cuidadosamente para obtener la máxima productividad de todas las herramientas.

Get more details about DURMAPRESS®’s DP-ES PRO SERIES CNC Servo Press Brake

The DP-Hybrid Servo offers three high-precision back-gauge options (2, 4, and 6 axes) for accurate and efficient bending of complex parts.

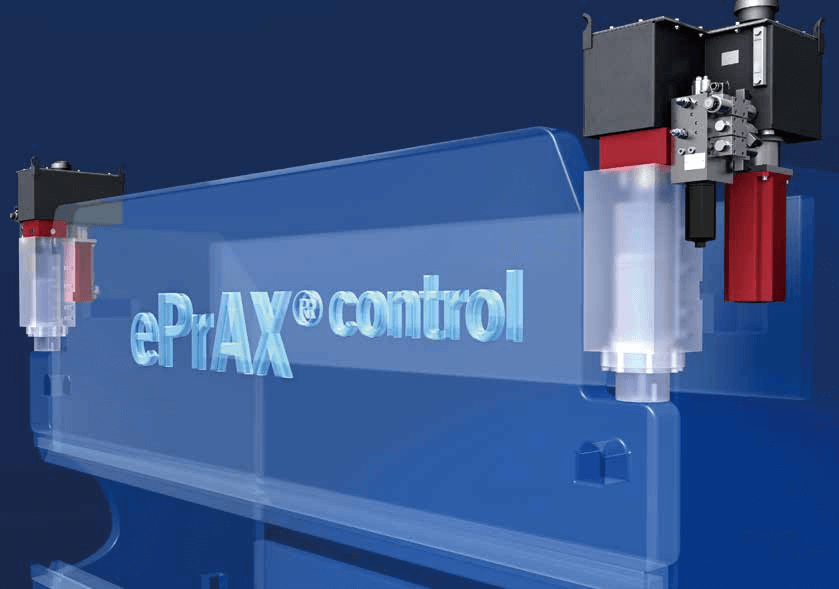

El sistema de control ePrAx® es un innovador servoaccionamiento para frenos de prensa, que presenta una interfaz de cilindro extremadamente sencilla, sin tubos externos. La sencilla interfaz entre el accionamiento y el cilindro facilita la instalación del cilindro del cliente. Como resultado, ePrAx@control ofrece a los clientes las siguientes ventajas:

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Teléfono : + 86 183 2557 2889

Correo electrónico : [email protected]

7/24

Fill in the information below to receive a free quote and product brochure. We will respond within 24 hours!