DP-ES SERIES

CNC servo Press Brake

The DP-ES Series Press Brake 3~4+1 Axis provides reliable precision and versatility for most bending applications. Increase your productivity with this durable and efficient solution.

The DP-ES Series Press Brake 3~4+1 Axis provides reliable precision and versatility for most bending applications. Increase your productivity with this durable and efficient solution.

Utillaje para prensas plegadoras

Portaherramientas

Sistema de control CNC

Luz

Interruptor de pedal

Hoja Frente Partidario

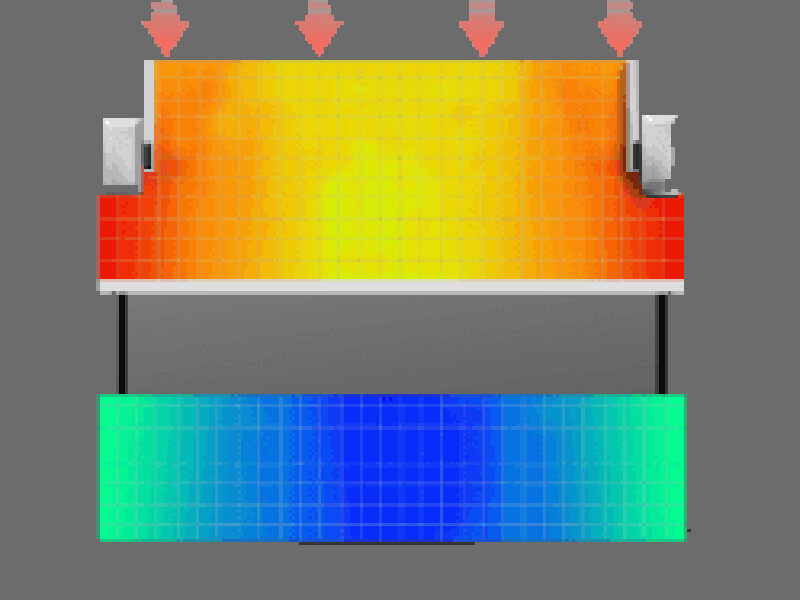

Coronación

La serie DA-50Touch ofrece soluciones modernas, compactas y versátiles para una amplia gama de aplicaciones de plegado sin comprometer la funcionalidad de la máquina.

Customize The Controller For Your DP-ES Series

El más potente de su clase Pantalla táctil de 10' con potente gráfico Todas las prestaciones de un cnc de alto nivel en un controlador económico y fácil de usar.

CybTouch 8 PS está pensado específicamente para prensas plegadoras sincronizadas. Como parte de la gama CybTouch, cuenta con una pantalla táctil en color intuitiva y viva y una gran integración de funciones.

Cada pieza puede garantizar una larga vida útil y reducir los costes de producción.

Las plegadoras Durmapress incorporan un robusto bastidor monobloque fabricado en acero de alto rendimiento, que garantiza una precisión y fiabilidad duraderas. Cada bastidor está templado y respaldado por una garantía de 15 años.

The standard DELEM DA53T CNC control system is convenient for operators and is most suitable for our DP-ES Servo series press brakes.

We use Taiwan PMI ball screw and linear guide for X-axis precision, ensuring higher accuracy than rod-based systems. The back gauge, controlled by a servo motor with a timing belt & wheel mechanism, offers precise positioning.

Aprovechando la fiabilidad de los componentes originales Schneider procedentes directamente de Francia, famosos por su estabilidad inquebrantable, su impresionante durabilidad y su prolongada vida útil.

Durmapress's self-developed Side Fast Clamp can be used with various series to complete bending work including heavy machines. The tooling replacement is smooth and durable.

We use the Siemens energy-efficient motor from Germany, designed to meet the daily production demands of our clientele seamlessly. This motor operates substantially more efficiently than standard motors.

It ensures consistent processing position and size by precisely controlling the workpiece stop. The adjustable Stopper Finger position and height accommodate various workpiece sizes and shapes.

The durable front supporter ensures long-lasting stability and precise positioning, reducing workpiece deformation and enhancing processing accuracy.

Accesorios de primera calidad de las principales marcas internacionales

Ensures precise, consistent bend angles across the workpiece, compensating for die deflection to reduce scrap and boost efficiency.

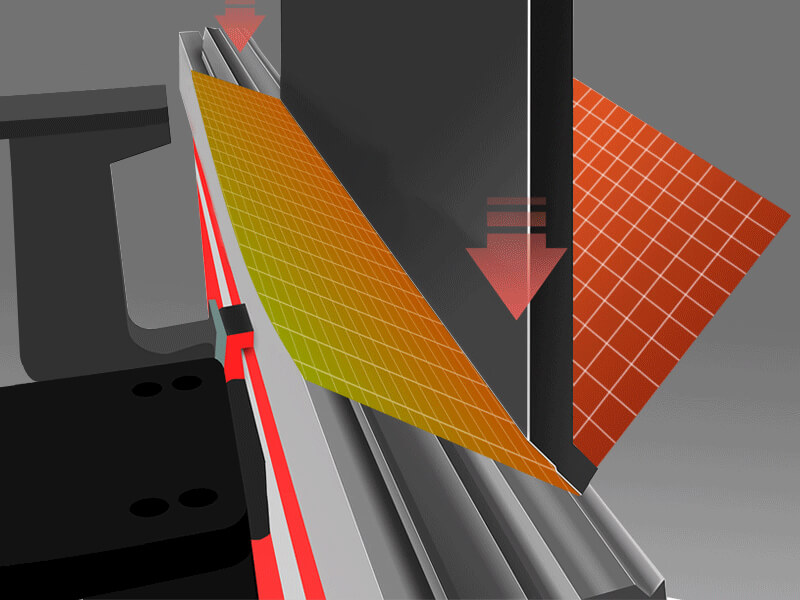

The European Type Sectioned 4V Die & Punch offers versatile bending, quick setup, and high precision for enhanced press brake performance.

Experimente una precisión sin igual con el sistema de medición de ángulos iMeasure Laser en colaboración con Data-M Engineering, que garantiza ángulos de curvatura exactos con una sola operación.

El sistema de protección láser DSP supervisa la intensidad y la ubicación de la radiación láser en tiempo real para garantizar que cualquier posible riesgo para la seguridad láser pueda detectarse a tiempo cuando la plegadora esté en funcionamiento.

Los últimos seguidores para el plegado de chapa pretenden optimizar las prestaciones de nuestras plegadoras reduciendo el tiempo de puesta a punto de la plegadora y simplificando el trabajo de los operarios. Estas ayudas al plegado proporcionan a los operarios una valiosa asistencia práctica.

Utilizamos las tecnologías innovadoras de WILA, incluyendo Safety-Click®, Smart Tool Locator® y el sistema de reemplazo E2M® para herramientas (de trabajo pesado), para mejorar la seguridad y conveniencia del reemplazo. La precisión y la ergonomía se adaptan cuidadosamente para obtener la máxima productividad de todas las herramientas.

Get more details about DURMAPRESS®’s DP-ES SERIES CNC Servo Press Brake

Durable alloy steel hydraulic cylinders with:

Diseñe una estructura de cuerpo estable para mejorar la estabilidad mecánica, reducir las vibraciones y garantizar la precisión y fiabilidad durante el funcionamiento a alta velocidad. La tecnología Durmapress no solo mejora la eficiencia, sino que también reduce el desperdicio de material en comparación con las plegadoras tradicionales.

Nuestras prensas plegadoras utilizan tecnología avanzada para garantizar que cada punto de tensión se distribuya uniformemente, logrando precisión y estabilidad durante el proceso de plegado del material. No importa lo compleja que sea la forma, nuestros equipos garantizan que cada punto reciba la fuerza adecuada, proporcionando una calidad y fiabilidad superiores para su producción.

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Teléfono : + 86 183 2557 2889

Correo electrónico : [email protected]

7/24

Fill in the information below to receive a free quote and product brochure. We will respond within 24 hours!