CNC press brake for plate bending in a variety of ways, this article will be bending processing from the relative position of the upper and lower molds and folded into the shape of the different aspects of the details of the bending of several common bending methods, and a detailed description of the bending process and precautions.

Classification of bending methods

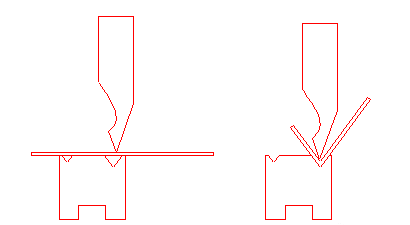

Gap bending concept and definition

Gap bending, is a specific way in the CNC press brake bending operation process. In this process, the upper mold and the lower mold does not need to be tightly pressed together, but by adjusting the depth of the upper mold into the lower mold opening, in order to obtain the desired bending angle. This method offers greater flexibility and precision than the traditional press fit bending method.

Characteristics and applications of gap bending

The characteristics of gap bending is that the deeper the upper mold into the lower mold, the smaller the bending angle; on the contrary, if the upper mold into the lower mold depth of the shallower, the larger the bending angle. Since the material has elasticity during the bending process, it is necessary to pre-bend an excessive amount of bending during the bending operation to control the amount of rebound after bending and ensure the accuracy of the bending angle.

Advantages of gap bending

The advantages of gap bending are mainly reflected in two aspects. First, because this bending method has a high degree of flexibility, making it possible to use a smaller number of molds to achieve a variety of angles of forming process. Secondly, since the upper and lower molds do not need to be tightly pressed together, the processing pressure required is relatively low, which reduces energy consumption and wear during processing to a certain extent.

Material to mold ratio in gap bending

In gap bending, the ratio of material to mold is also an important consideration. Specifically, when the material thickness is below 12.7mm, the ratio of B:V is 1:8; when the material thickness is between 12.7~22.2mm, the ratio of B:V is 1:10; when the material thickness is above 22.2mm, the ratio of B:V is 1:12. This ratio can be adjusted according to the specific bending requirements and material properties to achieve the best bending results.

Pressure bottom bending

Pressure bottom bending is a type of plate processing carried out on CNC press brakes. In this process, the plate is tightly pressed between the upper and lower molds, so that the plate under pressure plastic deformation, so as to achieve the preset bending angle and elbow radius. This type of bending is mainly used in the processing of sheet metal, and can realize the precise bending and forming of the sheet.

Characteristics of press bottom bending

Press-bottom bending is particularly suitable for mass production and high volume production, especially for processing sheet metal with a thickness of less than 2mm. Due to its unique processing method, the bending radius is relatively small, and at the same time, it can also ensure high bending accuracy, which can meet the needs of various complex shapes of sheet metal processing.

Precautions for press bottom bending

In the use of pressure bottom bending method of processing, need to pay attention to the working pressure should be greater than the gap bending pressure, usually requires the working pressure is more than three times the gap bending pressure. In addition, the angle of the press-bottom bending mold needs to be adapted to the angle of the plate and the material properties to ensure the accuracy of the bending and the forming quality of the plate. In addition, the ratio design of the mold is also very important, the general recommended ratio of the mold is B: V = 1:6, which can ensure the stability and accuracy of bending.

In general, press-bottom bending is an efficient and accurate way of sheet metal processing, suitable for a variety of high-volume production occasions. However, in the actual operation process, you need to pay attention to the setting and adjustment of various parameters to ensure the quality and precision of bending.

Working tonnage

Working tonnage, a term often mentioned in engineering and manufacturing, is an important indicator used to measure the force required during the bending operation. Specifically, working tonnage refers to the amount of pressure required to perform a bending operation. This pressure is applied to the material by a press brake or press in order to plastically deform it to form the desired bent shape.

Explanation of Factors Affecting Working Tonnage

Various factors affect the working tonnage, including the following:

- bending radius: the smaller the bending radius, the greater the working tonnage, as more pressure is required to bend the material to a smaller radius.

- bending method: different bending methods, such as U-bending, V-bending, etc., the working tonnage requirements will be different.

- Die ratio: die ratio refers to the ratio of the cross-sectional area of the die to the cross-sectional area of the material, the larger the die ratio, the greater the working tonnage.

- elbow length: the longer the length of the elbow, the greater the working tonnage, because more pressure is needed to make the material in a longer length of plastic deformation.

- thickness and strength of the bending material: the greater the thickness and strength of the material, the greater the working tonnage, because more pressure is needed to overcome the bending strength of the material.

Calculation of working tonnage in detail

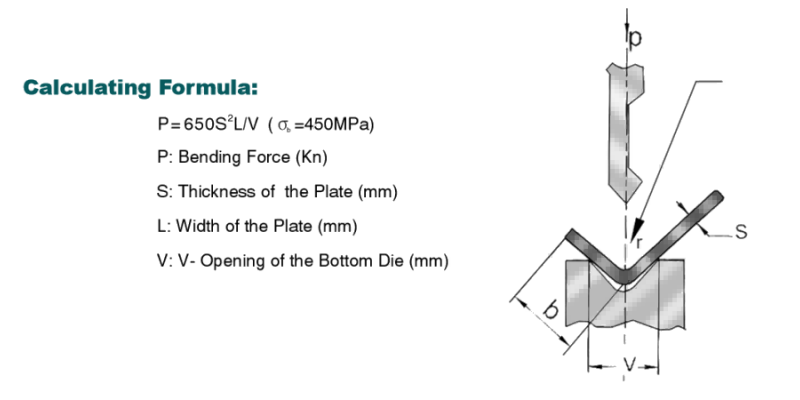

Calculation methods for working tonnage are usually based on certain assumptions and simplifications to facilitate engineering calculations. A common calculation method is to use the bending pressure approximation formula: P = 650s²L/1000v, where P represents the working tonnage, S represents the thickness of the material, L represents the width of the material, and V represents the bending speed. This formula provides an estimate of the working tonnage, but in practice, it may need to be adjusted according to the specific situation.

In practice, the calculation is usually based on the strength of the material σb = 450N/mm², this is because σb = 450N/mm² is a commonly used strength standard for engineering materials. Also, the values provided in the table are based on the bending pressure at a sheet length of one meter, which is a commonly used reference value.

Summarizing

Working tonnage is an important concept in engineering and manufacturing that reflects the amount of pressure required in a bending operation. A number of factors influence working tonnage, including bending radius, bending method, die ratio, elbow length, and the thickness and strength of the material being bent. Calculating working tonnage usually requires the use of certain formulas and assumptions for engineering applications.

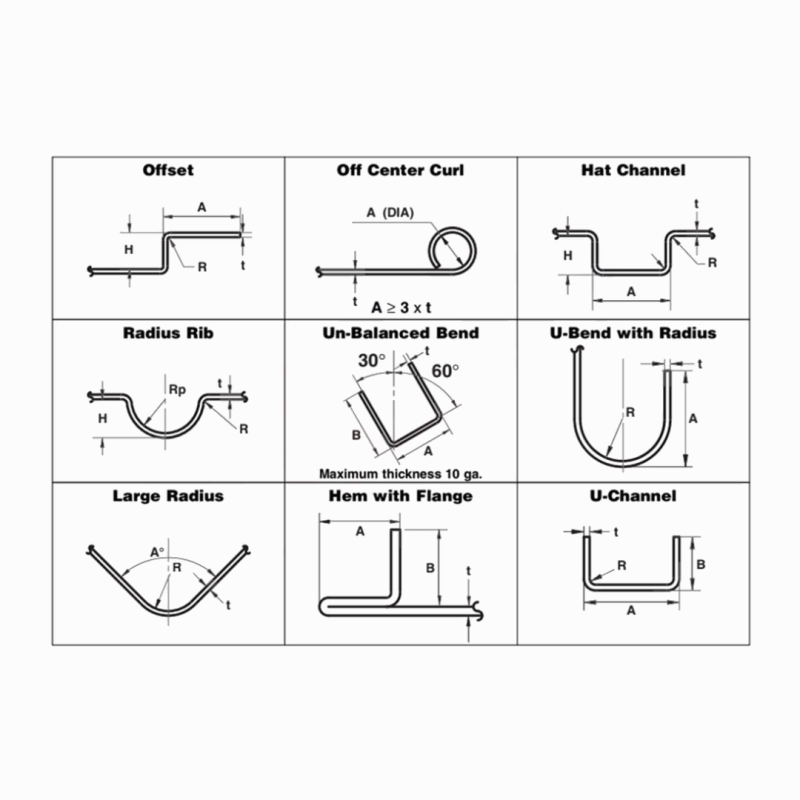

Bending shape classification details

L-bending classification analysis

In bending processing, L-bend is a common bending shape, which can be categorized into two types: 90˚ bend and non-90˚ bend. The 90˚ bend refers to the bending of two edges perpendicular to each other, forming a right angle; while the non-90˚ bend refers to the bending of two edges not at right angles, but at a certain angle. When L-bending is performed, it can be categorized into general processing (L>V/2) and special processing (L<V/2) based on the relationship between the length of the bend (L) and the width of the opening (V).

Reminder of Precautions

When performing L-bending processing, the following points need to be noted: first, select the appropriate mold, which depends on the material of the processed material, plate thickness, and the forming angle; second, pay attention to the way of leaning during processing and the movement of the rear set of gauges in the various ways of leaning processing.

Detailed description of N-fold

N-fold is a bending shape that adopts different processing methods depending on the shape. When bending, the inner dimension of the material should be larger than 4mm to ensure the stability and accuracy of bending.

Reminder of Precautions

During the N-folding process, care should be taken to ensure that the angle of the leaning position is slightly less than 90 degrees to facilitate subsequent processing operations. At the same time, after bending L-fold, the angle should be ensured at 90 degrees or slightly less than 90 degrees to facilitate the processing of leaning position.

Z-bending analysis

Z-bend, also known as section difference, refers to a positive and negative bending shape. It can be divided into two types: beveled edge segment difference and straight edge segment difference.

Reminder of Precautions

When processing Z-bend, it is necessary to ensure that the processing angle of L-bend must be in place, generally required to be 89.5 ~ 90 degrees. In addition, when pulling after the post-setting gauge, it is necessary to pay attention to the deformation of the workpiece in order to prevent the occurrence of defective products.

Explanation of Reverse Folding and Flattening

Reverse folding and flattening, also known as pressing the dead edge, is a processing step. It is processed by first bending the insertion depth to about 35 degrees, and then flatten it with the flattening mold until it is flat and tight.

Reminder of Precautions

When processing the dead edge, you need to pay attention to the parallelism of the two sides to ensure processing quality. For shorter dead edges, you can use the padding processing method to improve processing efficiency.

Analysis of Press Hardware

Pressing hardware is a kind of processing method of using folding bed to press and mortise hardware, which requires the use of concave molds, jigs and other auxiliary molds for processing.

Cautions and Reminders

In the process of pressing hardware, if the shape of the workpiece needs to be avoided, then it is necessary to take measures to avoid the position. After the processing is completed, it is necessary to test whether the torque and thrust are up to the standard, and whether the hardware and the workpiece are flat and tight to ensure the quality of the product.

Resuma

Through the above detailed introduction of CNC press brake several bending methods and precautions, I hope to help you better understand and apply these technologies to improve productivity and product quality. In the actual process, according to different bending shapes and processing requirements, the need to choose the appropriate mold and processing methods, while paying attention to a variety of precautions to ensure that the quality and accuracy of the bending process.

Quiénes somos

Durmapress se especializa en el diseño, la fabricación y la venta de diversos equipos de procesamiento de metales, como plegadoras, cizallas, punzonadoras, máquinas de corte por láser, etc. La empresa se fundó en 2000. Con años de experiencia y acumulación de tecnología. DurmaPress se ha convertido en una de las marcas más conocidas de la industria china de maquinaria para el procesamiento de metales.

Póngase en contacto con nosotros

Entradas recientes

Categorías

Síguenos

Nuevo vídeo semanal

Más información

Si tiene alguna información sobre nuestros productos, póngase en contacto con nosotros y le responderemos en 24 horas.

-300x169.jpg)

-300x169.jpg)