CNC Press Brake

General Características

- The main structure and characteristics of CNC Press Brake:

1. The frame adopts all-steel structure. The left and right vertical plates, working table and pressure plate are welded into a whole structure. After welding, the internal stress is eliminated by tempering. The whole machine has good rigidity, no deformation and high stability.

2. Important parts such as the fuselage and slider are all analyzed by ANSYS finite element analysis software Guarantee machine The reliability of the bed.

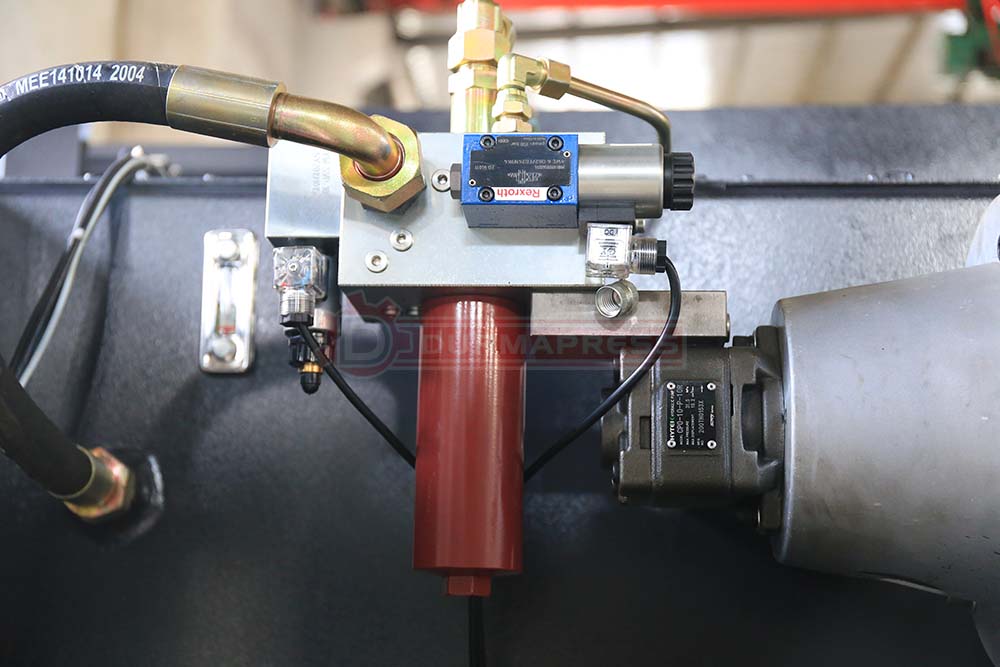

3. Hydraulic transmission, stable and reliable.

4. The mechanical block and torsion shaft are synchronized with high precision.

5. Backgauge distance and slider stroke are divided into manual control and numerical control system control, which is convenient and quick.

6. The oil cylinder is forged, quenched and tempered, finely ground, hard chrome plated and other processes, and are equipped with imported sealing rings to prevent oil leakage.

7. The hydraulic unit adopts the oil circuit integrated hydraulic system, which reduces pipeline installation and has a beautiful and simple appearance. 8. The hydraulic components are selected from famous brand products to ensure the reliability and safety of the machine tool operation.

9. The machine tool is powered by a three-phase system power supply (380V), and the control circuit voltage (220V)

Controlled by

The transformer is provided, and the DC power supply (+24V) required to execute the circuit solenoid valve is provided by the transformer and the silicon rectifier.

DA53T CNC Controller From Delem

Datos del controlador

- "Navegación táctil con teclas de acceso rápido

- TFT en color de alta resolución de 10,1

- Hasta 4 ejes (Y1,Y2 + 2 ejes aux.)

- Control de la coronación

- Biblioteca de herramientas, materiales y productos

- Servocontrol y control de convertidores de frecuencia

- Advanced Y-axis control algorithms for closed-loopas well as open-loop valves.

- TandemLink (opción)

- Interfaz de memoria USB

- Programa informático Profile-T offline

DA53T CNC Press Brake Main Components

Bastidor de la máquina

The foundation of every Durmapress press brake is a solid, mono-block frame which made from high yield steel. Which means our press brakes will perform accurately and reliably year after year. Every press brake frame is tempered. We' re so confident in our frames so that we offer a 15-year warranty with our standard machines.

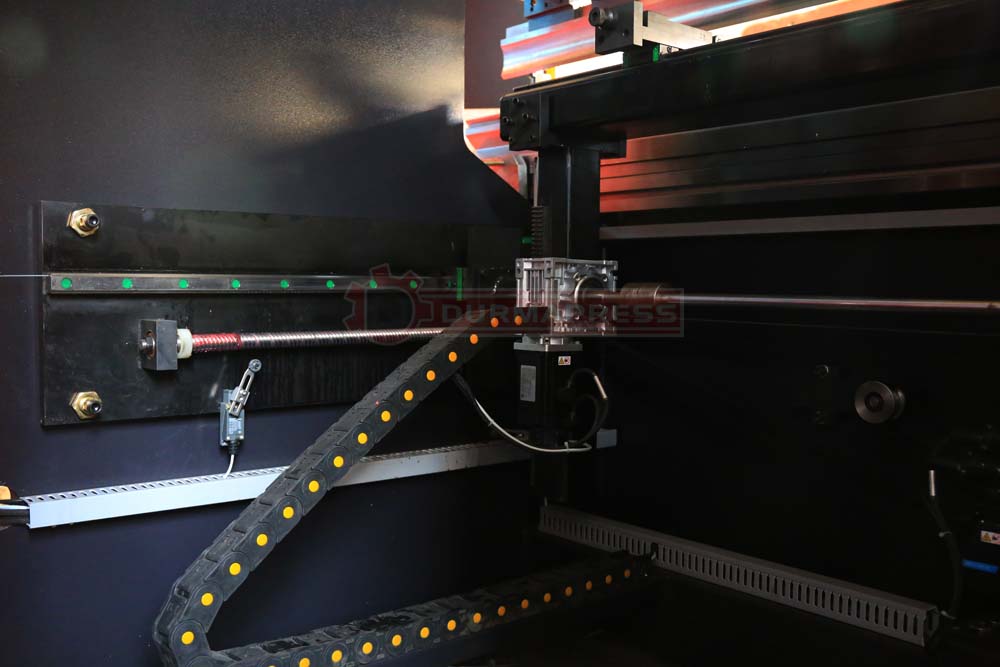

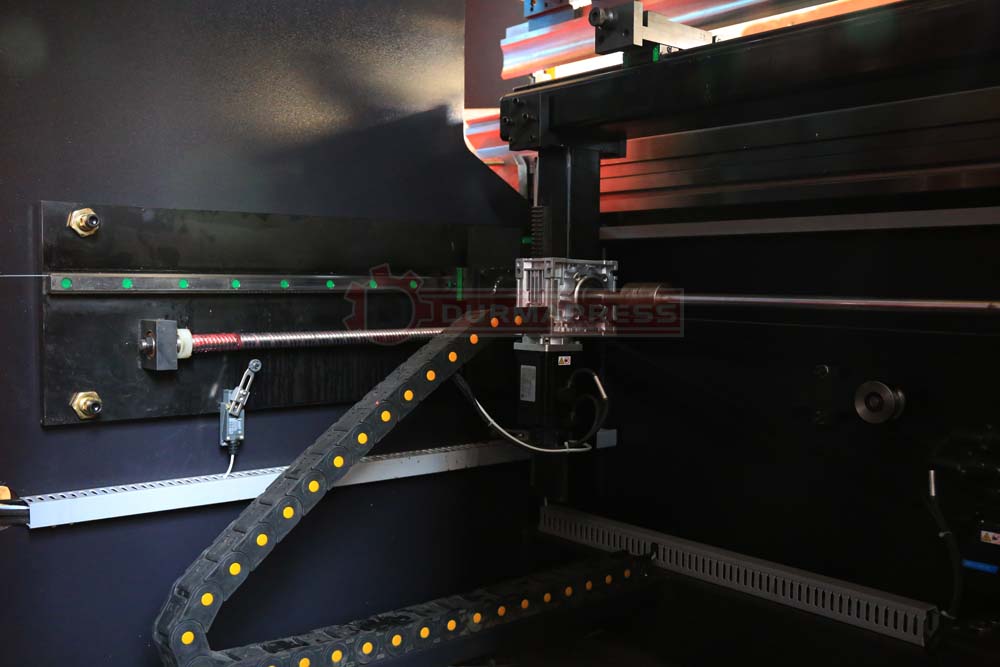

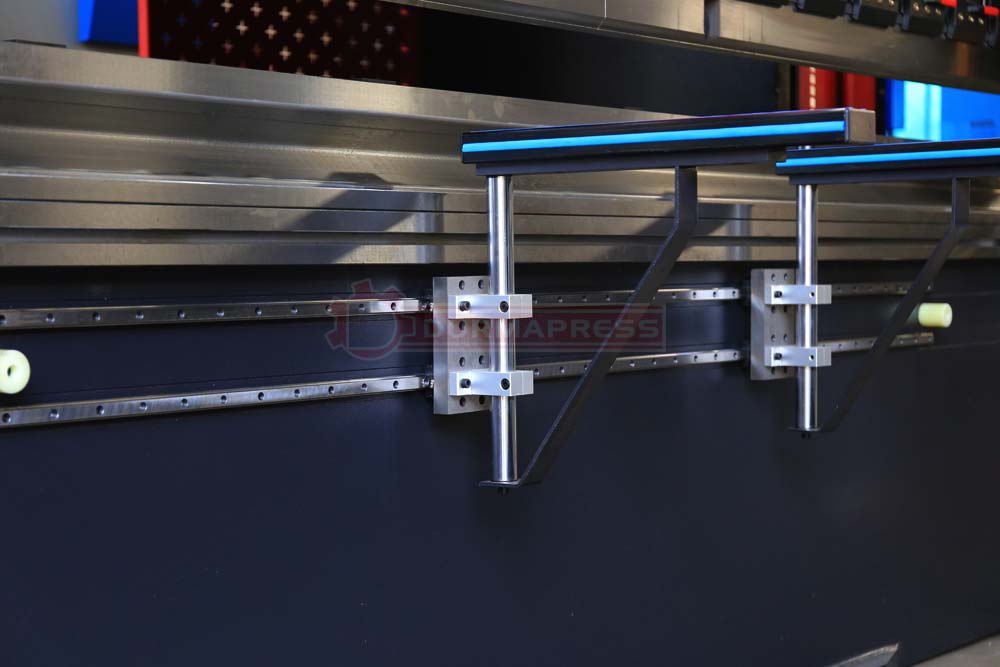

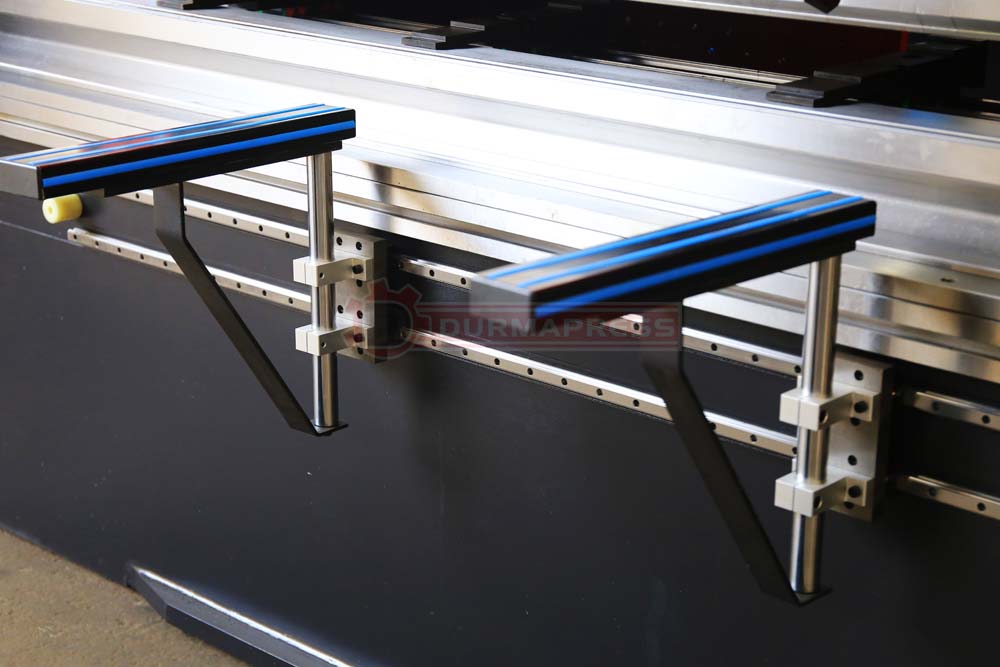

BackGauge

Utilizamos el husillo de bolas PMI de Taiwán y la guía lineal para asegurar el movimiento del eje X con mayor precisión que el uso de la varilla. Y el tope trasero adopta un mecanismo de correa dentada y rueda controlado por un servomotor en lugar de un motor paso a paso. La altura del dedo del tope trasero se puede ajustar manualmente. En total hay TRES piezas de dedos para posicionamiento.

Utillaje para prensas plegadoras

The standard top punch and dual-V bottom die are specially designed for bending sheet metals. More press brake toolings can be selected as per your practical use. Material and HRC47 degree values are marked on it

OTROS COMPONENTES

| Seri-al NO. | Nombre | Numerical Value | Unidad | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40T/2500 | 63T/2500 | 63T/3200 | 63T/4000 | 80T/2500 | 80T/3200 | 80T/4000 | 100T/2500 | 100T/3200 | 100T/4000 | 125T/3200 | 125T/4000 | 160T/3200 | 160T/4000 | 200T/3200 | 200T/4000 | 250T/3200 | 250T/4000 | 300T/3200 | 300T/4000 | 300T/6000 | 400T/3200 | 400T/4000 | 400T/6000 | 500T/6000 | 600T/6000 | |||||||||||||||||||||||||||||||

| 1 | CNC Control Axis | 3+1 axis ( Y1, Y2, X + V Crowning ) Optional R axis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | Nominal force | 4000 | 630 | 630 | 630 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1250 | 1250 | 1600 | 1600 | 2000 | 2000 | 2500 | 2500 | 3000 | 3000 | 3000 | 4000 | 4000 | 4000 | 5000 | 6000 | KN | ||||||||||||||||||||||||||||

| 3 | Bending length | 2500 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 6000 | 3200 | 4000 | 6000 | 6000 | 6000 | mm | ||||||||||||||||||||||||||||

| 4 | Slider Stroke | 150 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 250 | 250 | 200 | 200 | 250 | 320 | 320 | 320 | 320 | 320 | mm | ||||||||||||||||||||||||||||

| 5 | Daylight | 430 | 470 | 470 | 470 | 470 | 470 | 470 | 470 | 470 | 460 | 470 | 470 | 470 | 460 | 470 | 470 | 470 | 470 | 500 | 500 | 540 | 560 | 560 | 560 | 560 | 560 | |||||||||||||||||||||||||||||

| 6 | Profundidad de garganta | 250 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 520 | 520 | 280 | 280 | 400 | 400 | 400 | 400 | 470 | 500 | |||||||||||||||||||||||||||||

| 7 | Table width | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 160 | 160 | |||||||||||||||||||||||||||||

| 8 | Working table height | 900 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 3150 | 1000 | 1000 | 1000 | mm | ||||||||||||||||||||||||||||

| 9 | Working Speed | Full Load-speed | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 120 | 130 | 120 | 110 | 110 | 150 | 150 | 90 | 85 | 85 | 85 | 85 | 85 | Mm/sec | |||||||||||||||||||||||||||

| Work-speed | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 9 | 9 | 9 | 9 | 9 | 0-9.5 | 0-9.5 | 9 | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 | ||||||||||||||||||||||||||||||

| High-return speed | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 95 | 95 | 95 | 95 | 95 | 110 | 110 | 100 | 85 | 85 | 85 | 75 | 85 | ||||||||||||||||||||||||||||||

| 10 | CNC Backguage | Max Travel X- Axis | 400 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 500 | 500 | 800 | 550 | 550 | 550 | 550 | 550 | MM | |||||||||||||||||||||||||||

| Max Travel R- Axis | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 150 | 150 | 200 | 150 | 150 | 150 | 150 | 150 | MM | |||||||||||||||||||||||||||||

| Finger Block | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 6 | 6 | 6 | PC | |||||||||||||||||||||||||||||

| 11 | Capacity | Hydraulic pressure | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | Bar | |||||||||||||||||||||||||||

| Motor Power | 5.5 | 5.5 | 7.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 15 | 15 | 18.5 | 18.5 | 22 | 22 | 22 | 30 | 30 | 30 | 37 | 45 | Kw | |||||||||||||||||||||||||||||

| Oil Tank Capacity | 200 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Lts | |||||||||||||||||||||||||||||

| 12 | Machine weight | 2300 | 4800 | 5400 | 6200 | 5800 | 6300 | 7800 | 8500 | 8500 | 9600 | 8800 | 9800 | 10200 | 10500 | 14000 | 15000 | 15500 | 16500 | 16800 | 17800 | 24500 | 23000 | 26500 | 32500 | 40000 | 6550 | Kgs | ||||||||||||||||||||||||||||

| 13 | Overall dimension | Longitud | 2850 | 4550 | 4550 | 4550 | 2850 | 3550 | 4550 | 2850 | 3650 | 4550 | 3850 | 4550 | 3550 | 4550 | 3550 | 4360 | 4350 | 4350 | 3550 | 4550 | 6350 | 3850 | 4550 | 6550 | 6550 | 2350 | mm | |||||||||||||||||||||||||||

| Anchura | 1860 | 1950 | 1950 | 1950 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 3580 | ||||||||||||||||||||||||||||||

| Altura | 1900 | 2150 | 2150 | 2150 | 2250 | 2250 | 2250 | 2450 | 2450 | 2450 | 2480 | 2480 | 2680 | 2680 | 2880 | 2880 | 2980 | 2980 | 3180 | 3180 | 3200 | 3180 | 3180 | 3180 | 3380 | |||||||||||||||||||||||||||||||

| 14 | Requisitos de potencia | AC 220V~480V,3ph,50/60HZ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||