características

- Funcionamiento inteligente totalmente automatizado.

- La máquina dobla, alimenta y gira los tubos eléctricamente, mientras que el sistema hidráulico gestiona la sujeción y el desplazamiento del mandril.

- Los usuarios pueden elegir entre los métodos de refrigeración por ventilador, agua o aceite según sus preferencias.

- Equipada con una pantalla táctil compatible con varios idiomas, un controlador PLC (PC industrial Windows XP opcional), que proporciona un control eficaz y fácil de usar.

- Incluye una función de autolubricación para facilitar el mantenimiento.

- Las piezas eléctricas e hidráulicas proceden de reputados fabricantes de Japón, Francia y Alemania.

- Basada en la tecnología básica de Taiwán, establecida desde 1989, garantiza la fiabilidad y la innovación.

durmapress

Descripción de los componentes principales

Accesorios estándar para la máquina curvadora de tubos CNC

Cuerpo de la máquina

El fuselaje se sujeta una vez en acero tras la soldadura y se procesa en el centro de mecanizado CNC pentaedro como un todo. La tensión interna se elimina mediante tratamiento térmico y recocido para garantizar una rigidez y una precisión de mecanizado extremadamente altas.

Molde de plegado

Utiliza moldes de curvado especializados para dar forma a los tubos con precisión y uniformidad. Moldes personalizables para adaptarse a distintas dimensiones de tubos y requisitos de curvado.

sistema de refrigeración de aceite

Equipado con un sistema de refrigeración por aceite para gestionar y regular la temperatura durante el funcionamiento. Mejora el rendimiento general y la eficiencia de la máquina al evitar el sobrecalentamiento.

servomotor

Proporciona un control de posición de alta precisión, lo que permite un plegado y posicionamiento precisos. Con alta velocidad y aceleración, puede lograr un movimiento rápido.

Pantalla táctil

Interfaz de pantalla táctil fácil de usar para un control y funcionamiento sin problemas de la curvadora de tubos. Controles intuitivos y pantalla visual para una programación y supervisión eficaces.

Herramienta aleatoria

Incluye un juego de herramientas aleatorio que proporciona versatilidad para diferentes tareas de plegado. Permite una amplia gama de opciones y configuraciones de plegado para satisfacer diversas necesidades de producción.

Pida presupuesto ahora

Póngase en contacto con nosotros para obtener más información sobre la laminadora hidráulica

Por qué elegirnos

de principio a fin

Durmapress siempre se adhiere al concepto de poner a los clientes en primer lugar en toda la experiencia de compra, y optimiza e innova continuamente el proceso de producción para satisfacer las necesidades de todas las empresas de fabricación grandes, medianas y pequeñas.

- Más de 20 años de experiencia

- Máquinas personalizadas

- Perfecto sistema posventa

- Disponibilidad 24/7

Más información

Por qué elegir la máquina curvadora de tubos CNC?

1

Controladores de renombre

Utiliza controladores de renombre (Mitsubishi, Yaskawa, Delta) para un rendimiento estable.

2

Gran almacenamiento de CPU

Dispone de una gran CPU que almacena 400 archivos, con almacenamiento ampliable mediante software y disco duro adicionales.

3

WINDOWS Ordenador industrial

Equipado con un ordenador industrial WINDOWS para la gestión de servomotores y archivos, que permite la edición ilimitada en discos duros/soft.

4

Entrada de pantalla táctil personalizable

Entrada en pantalla táctil para personalizar el valor de compensación, la velocidad y la holgura de desmoldeo en función del material.

5

Entrega flexible de material

Permite la entrega directa/envolvente de material y la conversión automática de coordenadas XYZ a YBC.

6

Curvado eficiente de tubos

Cada codo tubular puede tener 5 secuencias de acción y 10 secciones de velocidad, lo que mejora la eficacia y reduce los puntos de interferencia.

fábrica de durmapress

Ver el vídeo

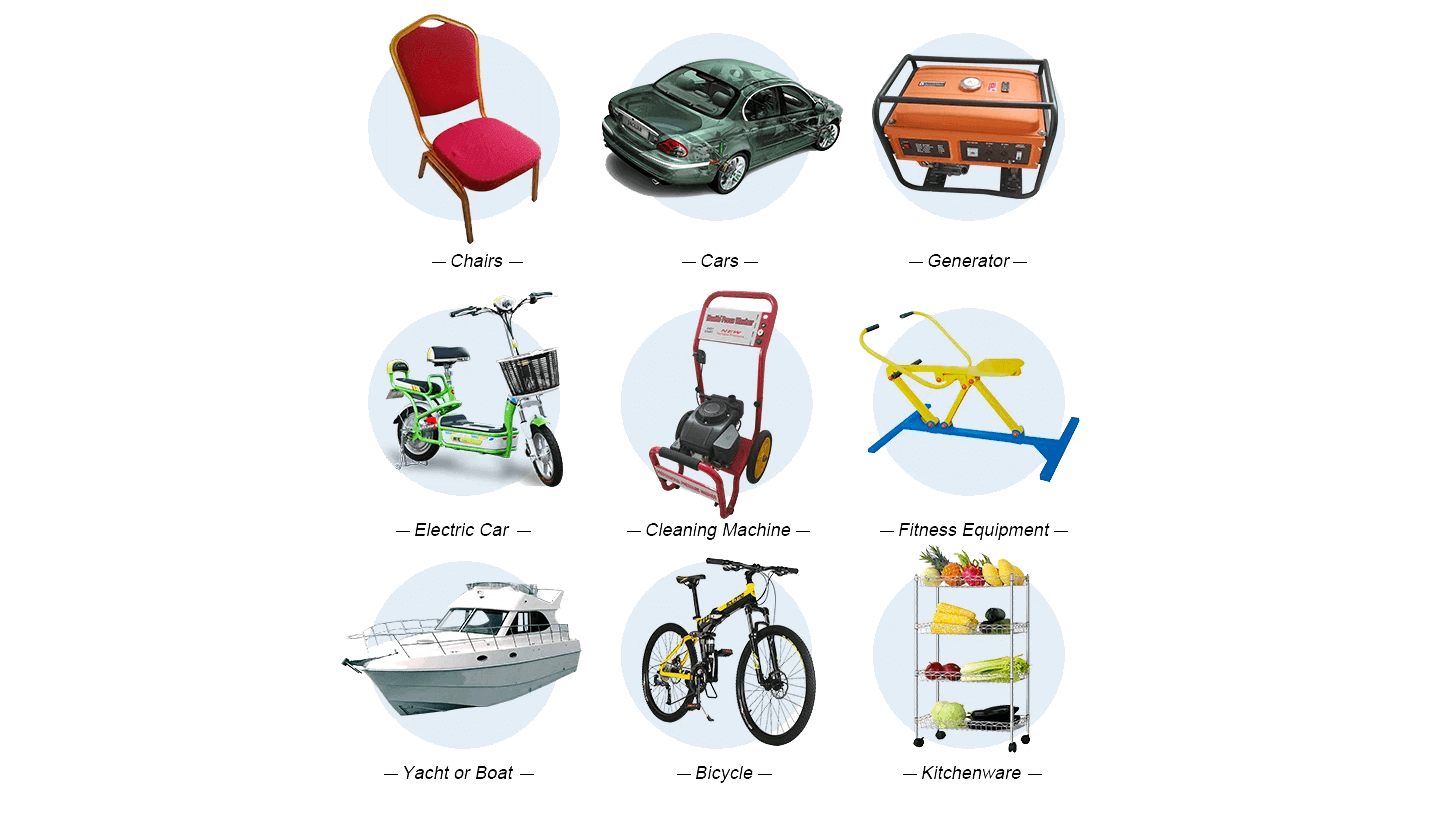

aplicaciones

Póngase en contacto con nosotros

Ubicación

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Póngase en contacto con nosotros

Teléfono : + 86 183 2557 2889

Correo electrónico : [email protected]

Nuestro horario

7/24

Síguenos