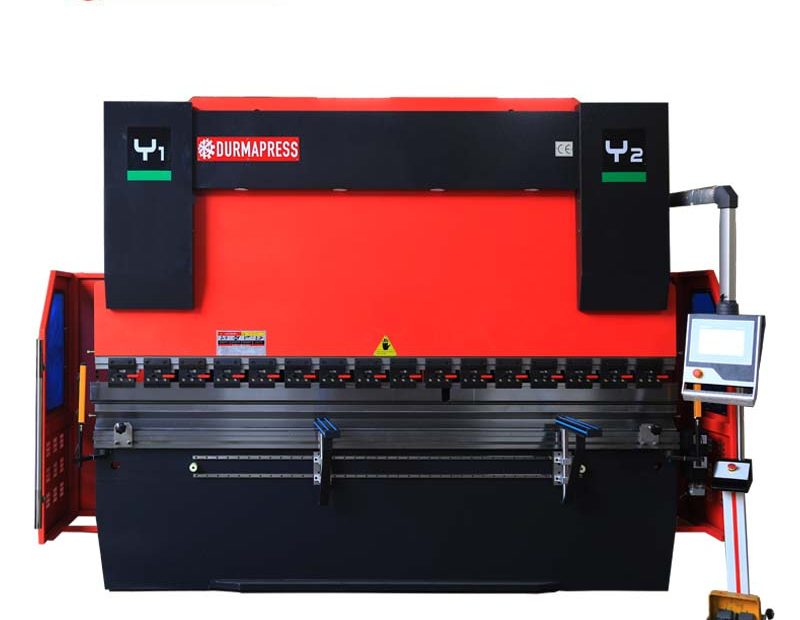

Máquina curvadora de chapa hidráulica serie WC67Y Prestaciones y características

WC67Y serie hidráulica máquina dobladora de placas Rendimiento y características: Toda la estructura soldada de acero, la vibración para eliminar el estrés, de alta resistencia mecánica, buena rigidez; Accionamiento hidráulico, estable y fiable; Bloque mecánico, la sincronización del eje de torsión, de alta precisión; La distancia del material posterior, la carrera de deslizamiento superior adopta el ajuste eléctrico, dispositivo de ajuste fino manual, pantalla digital; La matriz superior está equipado con un mecanismo de compensación de desviación, y el mecanismo de compensación de desviación inferior se puede utilizar para máquinas con una longitud de 250 toneladas ... Leer Más "Máquina curvadora de chapa hidráulica serie WC67Y Prestaciones y características