Advantages of light laser cutting machine

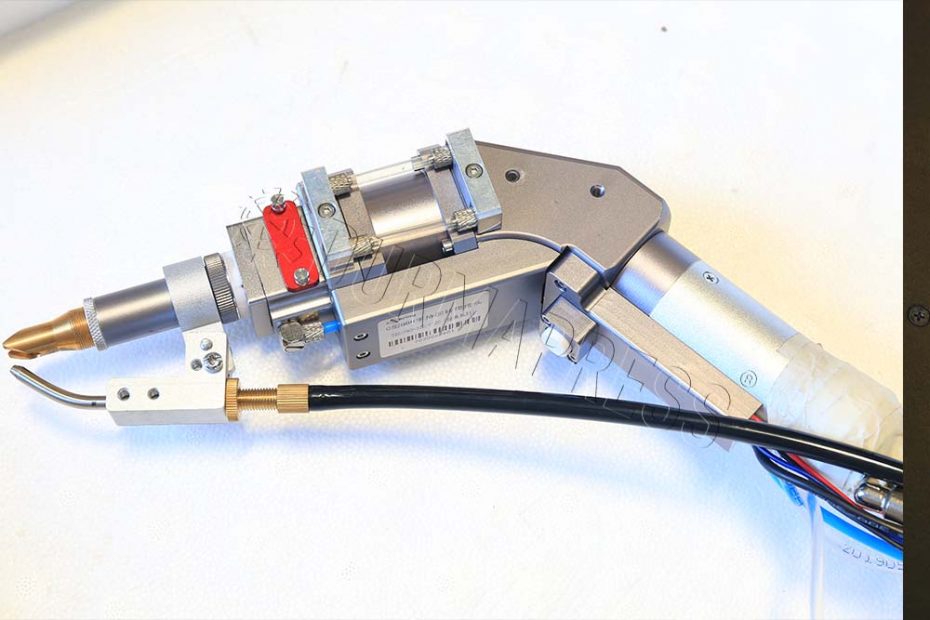

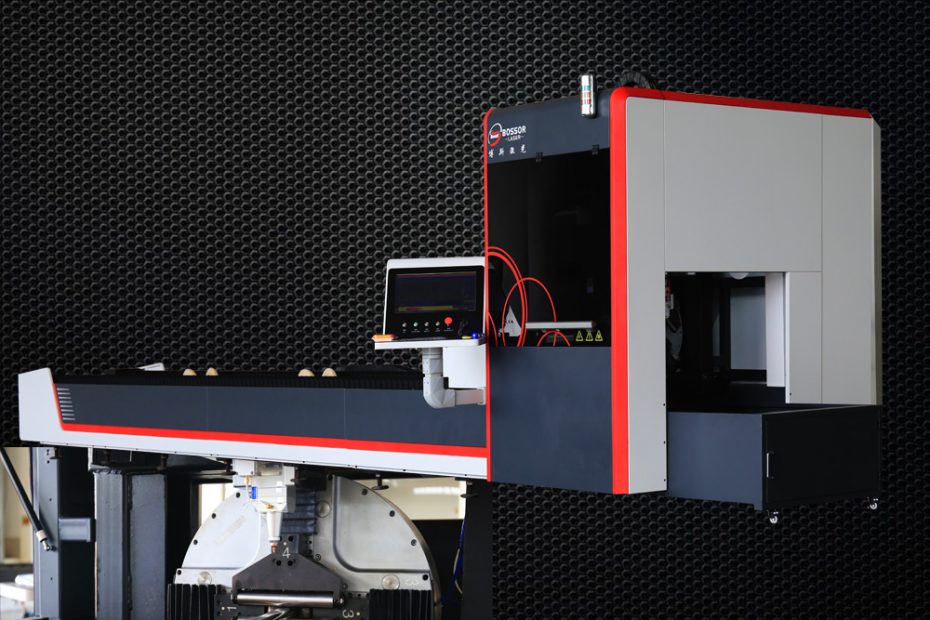

Advantages of light laser cutting machine: Low cost, low power cost, can blow air to cut all kinds of metal sheet. High cutting speed, high efficiency and labor saving. Spot quality, small deformation, smooth appearance, beautiful. Adopt imported servo motor and guide drive mechanism, high cutting precision. Using professional software can design all kinds of circles or text instant processing, flexible processing, simple operation, convenient. High stability, using imported light laser, stable performance, key parts of the service life of… Leer Más "Advantages of light laser cutting machine