Irish customer order Hydraulic Press Brake again

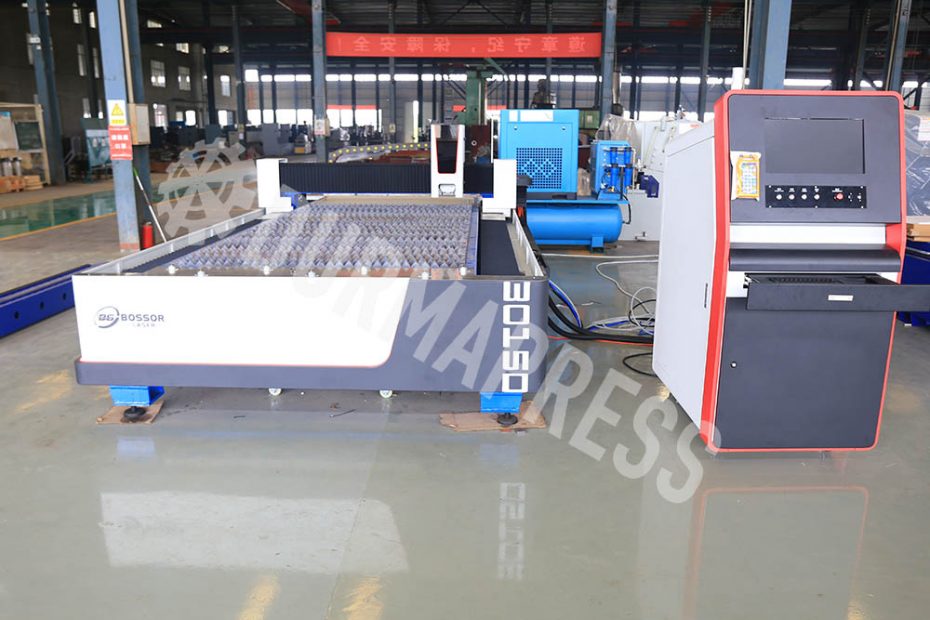

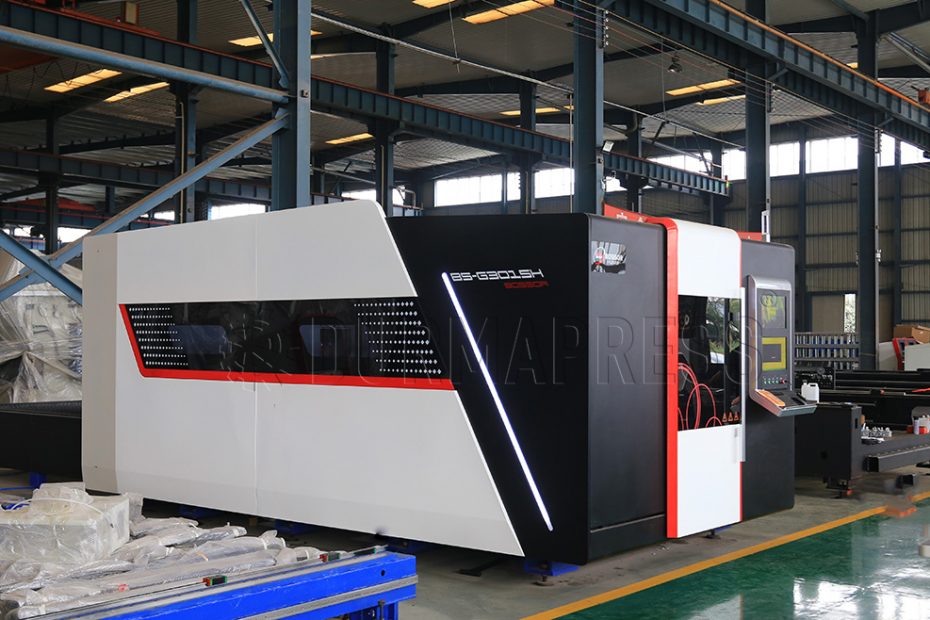

Irish loyal customers In 2022, our company had the privilege of working with a loyal customer, providing them with a high-quality hydraulic press brake. Today, this customer has placed another repeat order for a 40HG container of 2 sets hydraulic press brake and 2 sets hydraulic swing shearing machine, making the decision swiftly. This is primarily due to the outstanding quality of our previous equipment and the high level of trust the customer has in our company. Background of the… Leer Más "Irish customer order Hydraulic Press Brake again