Comparative Analysis Of Laser Cutting Machine, Plasma Cutting Machine And Flame Cutting Machine

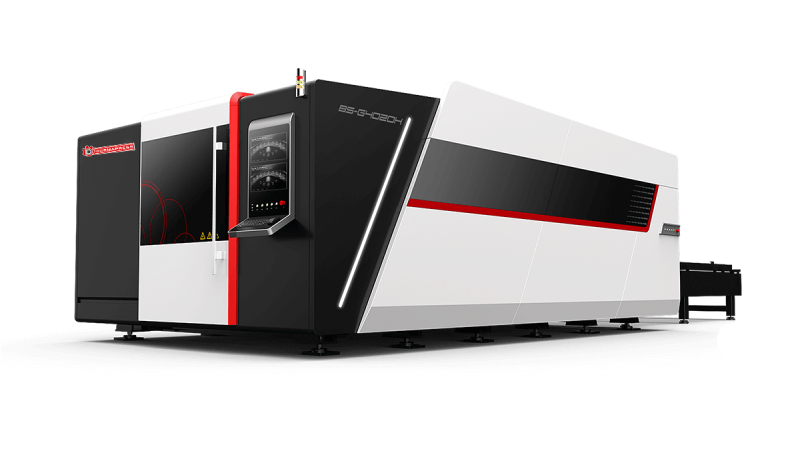

When it comes to metal cutting technologies, laser cutting machines stand out for their precision and versatility. Using a focused laser beam, these machines can cut through a variety of materials, including steel, aluminum, and even non-metallic substances with minimal distortion. Laser cutting is particularly advantageous for applications requiring intricate designs and fine details, as it provides a smooth finish and high accuracy. However, the initial investment and maintenance costs are higher compared to other cutting methods.

Plasma cutting machines offer a different set of advantages, particularly for thicker materials. By utilizing an electrically conductive gas to produce a plasma arc, these machines can efficiently cut through thick sheets of metal with high speed and efficiency. Plasma cutting is generally faster than laser cutting for thicker materials and is more cost-effective for heavy-duty industrial applications. While it may not provide the same level of precision as laser cutting, it is an excellent choice for projects where speed and material thickness are priorities.

Flame cutting machines, also known as oxy-fuel cutting machines, are among the oldest and most cost-effective methods for cutting thick steel plates. Using a combination of oxygen and fuel gas, flame cutting machines can handle extremely thick materials that other cutting methods might struggle with. This technique is well-suited for heavy fabrication industries, but it lacks the precision and versatility of laser and plasma cutting. Additionally, the process generates a significant amount of heat, which can cause material distortion and requires careful handling.