características

- Diseño plano estándar líder en simplicidad y eficiencia.

- Máxima velocidad, corta 400 círculos pequeños por minuto.

- Velocidad máxima de 140 m y aceleración de 1,2 G para una precisión superior.

- Pioneros en un diseño globalmente integrado y fácil de usar.

- Plataforma de intercambio alto-bajo con un intercambio rápido de 15 segundos.

- Viga de aluminio fundido a presión y moldeado para mayor resistencia, que pesa sólo la mitad que las vigas de hierro tradicionales.

Potencia láser

1000 - 30000W

Área de procesamiento

3*1.5(m)/4*1.5(m)/4*2(m)/6*1.5(m)

Longitud

3-6 metros

Componente OPCIONAL

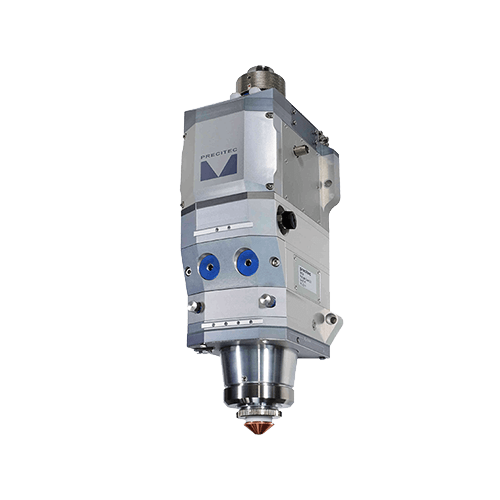

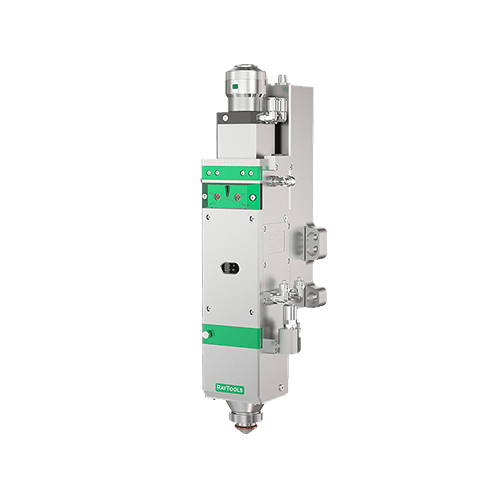

Cabezal de corte por láser

Personalice el controlador de su máquina de corte por láser de fibra óptica

precitec

Precitec ofrece soluciones adecuadas para todos sus requisitos y conceptos de máquinas. Se procesan materiales planos de diversos grosores de acero, acero inoxidable, aluminio o metales no ferrosos.

Raytools

Diseño modular de fácil mantenimiento. Doble circuito de refrigeración por agua. Enfoque automático para reducir la intervención humana y mejorar la eficacia de perforación y corte.

WSX

Este cabezal de corte se utiliza principalmente para láser de menos de 2000W. La estructura interna del cabezal láser está completamente sellada para evitar la contaminación de la lente óptica.

Componente OPCIONAL

Fuente láser

Personalice el controlador de su máquina de corte por láser de fibra óptica

Láser IPG

IPG Photonics es conocida por sus láseres de fibra de alta calidad, estables y duraderos, respaldados por una tecnología innovadora.

láser raycus

Raycus ofrece láseres de fibra rentables con un excelente rendimiento y una amplia gama de aplicaciones, ideales para diversas tareas de mecanizado de precisión.

láser máx.

Max proporciona láseres de fibra de alto rendimiento con una línea de productos diversa, que garantiza una calidad superior, fiabilidad y asistencia técnica completa.

Componente ESTÁNDAR

Otros componentes

Cada pieza puede garantizar una larga vida útil y reducir los costes de producción.

Bastidor de la máquina

El cuerpo de la máquina Durmapress cuenta con un robusto bastidor monobloque fabricado en acero de alto rendimiento, que garantiza una precisión y fiabilidad duraderas. Cada bastidor está templado y respaldado por una garantía de 15 años.

Fuente láser

Las fuentes láser desempeñan un papel fundamental en las máquinas de corte por láser, ya que ofrecen numerosas ventajas. Proporcionan gran precisión y exactitud, lo que permite cortar geometrías complejas con todo lujo de detalles.

Cama mecánica

Las bancadas mecánicas se diseñan y fabrican con gran precisión para proporcionar una plataforma de trabajo exacta. Esto es importante para aplicaciones que requieren un corte de alta precisión, como la fabricación de piezas diminutas o el montaje de precisión.

Lubricación automática

El sistema de lubricación automática puede proporcionar automáticamente lubricación a los componentes clave del equipo de forma regular o según los intervalos de funcionamiento establecidos, garantizando que el equipo mantenga siempre un buen estado de lubricación durante el funcionamiento a largo plazo.

Aire acondicionado

El funcionamiento de las máquinas de corte por láser suele generar una gran cantidad de calor, y el sistema de aire acondicionado puede ajustar la temperatura interior para garantizar un entorno de trabajo estable en diversas condiciones climáticas.

Cabezal de corte

El cabezal de corte es responsable de posicionar y dirigir con precisión el rayo láser a la superficie de la pieza. Debe ser capaz de controlar con precisión la posición y dirección del rayo láser para garantizar la precisión y exactitud durante el proceso de corte.

Componente estándar

Sistema de control CNC

Software CypCut

Sistema de control láser de bucle abierto de alto rendimiento

- Función especial de calibración de la presión del aire

- Punzón multietapa

- Control de la energía láser

- Búsqueda adaptativa de bordes

- Función Leapfrog

- Aceleración y deceleración automáticas en las curvas

- Corta moscas

- Compensación mecánica de precisión

Dispositivo opcional

Automatización de hojas multicapa warchouse

Unidad de clasificación de carga y descarga

- Reposición automática de materiales para la producción

- Sin personal, lo que reduce la mano de obra y los errores

- Un sistema estable garantiza la precisión de la recuperación

- Un posicionamiento preciso aumenta la eficacia

Pida presupuesto ahora

Obtenga más detalles sobre la máquina de corte por láser de fibra serie BS-D de DURMAPRESS

Materiales y energía

La demanda real también se ve afectada por la velocidad de corte, la calidad del corte, la eficacia del trabajo y otros factores. Por lo tanto, a la hora de elegir una potencia de máquina de corte por láser, consúltenos para asegurarse de que cumple los requisitos de su aplicación específica.

- Baja potencia (500W - 2000W): Adecuada para el corte de chapa fina, como acero inoxidable y acero dulce de hasta 6 mm de grosor, y materiales no metálicos como plásticos y madera fina.

- Potencia media (2000W - 6000W): Ofrece una mayor capacidad de corte para chapas más gruesas, como acero inoxidable de hasta 12 mm de grosor y acero dulce de hasta 16 mm de grosor.

- Alta potencia (6000W y superior): Diseñada para tareas de corte pesado, incluidas chapas gruesas (hasta 30 mm o más) y corte a alta velocidad de materiales finos y de grosor medio.

¿Por qué elegir la serie BS-D?

1

Alta precisión de corte

Está equipada con tecnología avanzada de corte por láser. Esta precisión es crucial para las industrias que requieren diseños intrincados o tolerancias ajustadas.

2

Versatilidad

Está diseñada para cortar una amplia gama de materiales, incluidos distintos tipos de metales (como acero, acero inoxidable y aluminio).

3

Eficacia y productividad

Gracias a su alta velocidad de corte y eficacia, puede agilizar los procesos de producción y aumentar la productividad.

fábrica de durmapree

Ver el vídeo

Fabricante de equipos punteros de tratamiento de metales

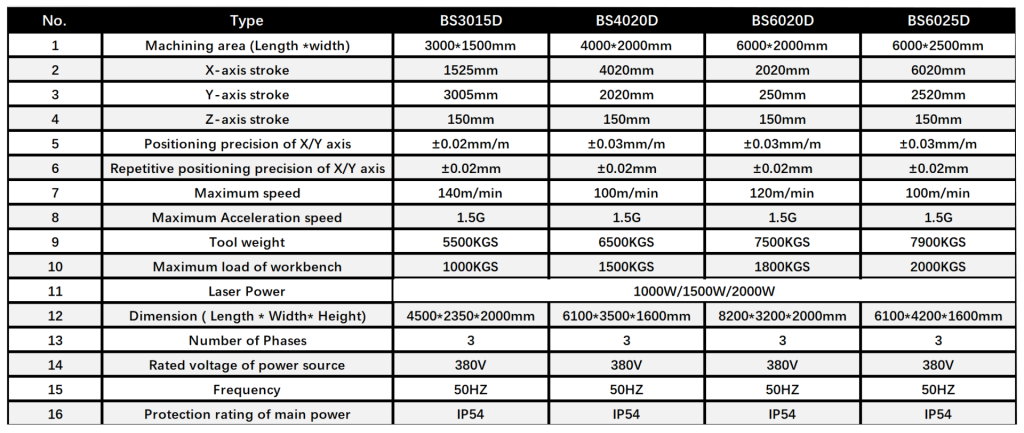

Parámetros del producto

productos relacionados

SERIE BS-D PRO

Máquina de corte láser de placas

Serie BS-G

Máquina de corte láser de fibra para tubos y placas

Póngase en contacto con nosotros

Ubicación

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Póngase en contacto con nosotros

Teléfono : + 86 183 2557 2889

Correo electrónico : [email protected]

Nuestro horario

7/24

Síguenos