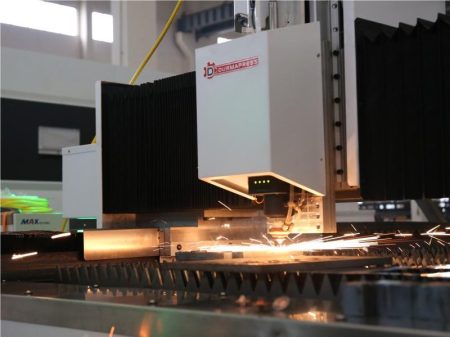

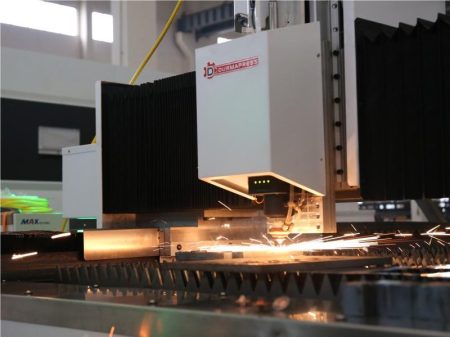

In today's modern manufacturing industry, environmental protection and efficient production continue to emerge and become the focus of the industry. This is because as society becomes increasingly concerned about environmental issues and natural resources become more and more limited, the manufacturing industry urgently needs to take measures to Sustainable green manufacturing methods to ensure that the production process has minimal impact on the environment. But at the same time, improving production efficiency is also an important goal in the current era of development. In this market environment of survival of the fittest, maintaining competitiveness and meeting market demand can provide impetus for sustainable development. Therefore, our company is actively seeking solutions to combine environmental protection with high efficiency, actively integrating advanced technology and continuously carrying out sustainable practices, with the aim of achieving more outstanding achievements in environmental protection and efficient production. This effort not only helps our company truly achieve sustainable development, but also helps us jointly create a greener, smarter and more efficient manufacturing development prospect. The laser cutting machine mainly discussed in this article has become a key green manufacturing technology in the manufacturing industry due to its high precision, high efficiency and low waste characteristics of laser cutting technology. In the following articles, we will delve into the innovation and application of laser cutting machines in terms of environmental protection and efficiency.

I. Innovation of laser technology in cutting head and autofocus system

A. Unique design and innovation of laser technology in cutting head

The cutting head of a laser cutting machine is an important part of the cutting machine. In the design of the cutting head, the lens and optical system need to ensure the focus and parallelism of the laser beam, so as to ensure that the laser beam can be accurately focused after entering the cutting head. On the target material, every cut is accurate during cutting. Through continuous research and optimization, researchers have continuously improved the design of focus and parallelism to ensure that the laser beam is more concentrated during the cutting process, reducing energy dispersion and ensuring cutting accuracy.

This unique design also reduces the energy loss of the laser beam during transmission. By optimizing the optical system, more energy is used for the cutting process, thereby greatly improving cutting efficiency and reducing energy waste.

In addition, researchers also focused on stability and durability when designing the cutting head. Through optimized optical system and structural design, the laser beam is ensured to remain stable during the cutting process, and the important thing is to reduce cutting errors caused by fluctuations or vibrations. Paying attention to stability not only improves cutting accuracy, but also extends the service life of the cutting head. Overall, the unique design of the laser cutting head is achieved through deep understanding and innovation to ensure that the laser can serve production work more stably and without error.

III. The impact of CNC technology on laser cutting machines

A. Application of CNC technology in laser cutting machines

The wide application of CNC technology allows laser cutting machines to play a more flexible role in the manufacturing industry. Through advanced digital control technology, operators can adjust various parameters in real time to adapt to different processing needs, making the production process more customizable. and strong adaptability, which can also be reflected from the fact that CNC technology promotes the improvement of manufacturing production processes and the improvement of product quality.

Digital control significantly improves production efficiency because under digital control, laser cutting machines can realize automated and intelligent production processes, reducing error rates and production costs, thereby significantly improving production efficiency. This efficient production method enables the manufacturing industry to quickly meet market demand and improve economic efficiency.

Secondly, changes in the production model of the manufacturing industry are also changes brought about by CNC technology. Precise digital control allows products to be highly consistent in size and shape, thereby improving product quality. At the same time, more flexible and personalized production methods have also emerged, which reflects that under digital control, the manufacturing process can be quickly adjusted and optimized according to market demand and consumer demand to meet diversified and personalized market needs. . Another very important point is that CNC technology is an important partner in promoting the transformation and upgrading of the manufacturing industry. Continuously updating technology and equipment is an important process to maintain competitive advantage. The introduction of CNC technology enables the manufacturing industry to achieve automated and intelligent production. This method improves production efficiency and product quality, and also brings more innovation and develop

IV. Application of environmentally friendly technology: smoking system and bed design

A. The contribution of the design of the smoking system to environmental protection

Almost all laser cutting machines today are equipped with efficient extraction systems, which play an important role in many industries. The system can accurately and efficiently handle the exhaust gas and waste materials generated during the cutting process, significantly reducing the negative impact on the environment. The quality improvement of the smoking system is inseparable from the extensive application of advanced filtration technology, which ensures that exhaust gas emissions comply with strict environmental standards and further improves the environmental performance of the entire cutting process.

The work of the high-efficiency smoking system of the laser cutting machine is divided into the following parts: First, the smoking device inhales the generated exhaust gas and filters it through high-efficiency filter materials. This step can effectively remove fine particles and harmful substances in the exhaust gas and reduce the pressure on the environment. Secondly, the filtered waste gas enters subsequent treatment equipment, such as activated carbon adsorption devices and ultraviolet decomposition devices. These equipment further process the harmful components in the exhaust gas to ensure that the discharged gas meets environmental protection standards. In this process, advanced filtration technology plays a key role. By using filter materials with high porosity and high surface area, they can effectively capture the harmful components in the exhaust gas. Tiny particles and harmful substances. In addition, the activated carbon adsorption technology used in the laser cutting machine has strong adsorption capacity and can quickly capture organic matter in the exhaust gas to prevent it from causing pollution to the environment. The powerful ultraviolet decomposition technology can effectively decompose harmful gases in the exhaust gas and reduce the risk of gas emissions. contamination level.

Through this complete set of efficient smoking systems, the laser cutting machine not only reduces environmental pollution, but also demonstrates the sustainable development of the entire industry in the field of laser cutting technology. Such equipment not only helps improve cutting efficiency and reduce production costs, but also minimizes negative impact on the environment.

B. How bed design improves the energy efficiency of machine tools

The optimized design of the machine tool bed reduces energy consumption and improves the energy efficiency of the machine tool. The use of renewable materials and lightweight design are also key factors in improving environmental friendliness. In order to further improve the performance and environmental protection of machine tools, manufacturers have chosen to comprehensively optimize machine bed design, energy utilization and material selection.

First of all, in terms of bed design, through continuous research and practice, a structural design with better rigidity and stability is adopted. This design not only improves the machining accuracy of the machine tool, but also can withstand greater cutting forces and vibrations, thereby extending the service life of the machine tool. The streamlined design of the bed is also a good way to improve energy efficiency, because by reducing the wind resistance on the bed surface, the cooling effect can be improved, thereby reducing energy consumption.

Secondly, in terms of energy utilization, an efficient energy-saving system is adopted. This type of system introduces digital control and can automatically adjust the power supply according to the needs of the processing process to avoid unnecessary waste of energy.

It is also important to work on material selection, so machine tool manufacturers are beginning to use renewable materials in large quantities. The waste produced during the processing of these materials has a low impact on the environment and is easy to recycle and reuse. Some manufacturers choose to adopt lightweight designs to reduce the overall weight of machine tools, reducing production costs and energy consumption during transportation.

The optimized design of the machine tool bed not only reduces energy consumption, but also significantly improves the energy efficiency of the machine tool. This is through the use of two key factors: renewable materials and lightweight design, which further.

V. The rise of the automated manufacturing era: welding robots

A. Application of welding robots in laser cutting machines

The introduction of automated welding robots further improves production efficiency. They can be integrated with laser cutting machines to achieve a seamless transition from cutting to welding, reducing human intervention and improving integrated production levels. Not only can they work efficiently with laser cutting machines, they can also further optimize the production process and achieve a seamless transition from cutting to welding. In this process, welding robots significantly reduce human intervention and improve the level of production integration, making the entire production process more efficient and smooth.

In the development and application of welding robot technology, on the one hand, through integration with laser cutting machines, welding robots can achieve precise cutting and welding of metal sheets, greatly improving production efficiency. On the other hand, while reducing human intervention, welding robots can also ensure stable product quality, reduce the rate of defective products, and improve the economic benefits of the enterprise.

In addition, the contribution of welding robots to environmental protection cannot be ignored. Compared with traditional welding processes, welding robots have obvious advantages in reducing welding smoke and energy consumption, which help improve the workshop working environment, reduce the risk of occupational diseases for employees, and reduce production costs.

At the same time, the promotion and application of welding robot technology also faces certain challenges. How to improve the intelligence level of welding robots so that they can better adapt to complex and changeable production environments, further reduce production costs, and improve production efficiency has become an important topic in the field of welding robot research. In addition, companies also need to increase the training of welding robot technical talents to meet the growing production needs.

B. How welding robots push the manufacturing industry towards automation

Automated welding robot systems perform welding tasks through precise procedures, which not only improves work efficiency but also reduces labor costs, which makes the manufacturing industry move closer to automation. These welding robot systems perform welding tasks through precise procedures, which not only greatly improves work efficiency but also reduces labor costs. Today, more and more companies are beginning to pay attention to automated welding technology to improve production efficiency, enhance competitiveness, and further promote the transformation and upgrading of the manufacturing industry. Welding robotic systems offer numerous advantages. First of all, the robot can work 24 hours a day, which greatly improves production efficiency. Compared with traditional manual welding, welding robots can complete a large number of welding tasks in a short time, shortening the production cycle. Secondly, the welding robot has highly precise control capabilities, which can achieve high-precision and high-quality welding effects and improve the product qualification rate. In addition, welding robots can also work in harsh environments, ensuring the safety of the production process and reducing the labor intensity of workers. However, the widespread application of welding robot systems also brings certain challenges. Issues such as how to ensure the safe operation, convenient maintenance and collaborative operation of welding robots with manual welding need to be solved urgently. In addition, companies also need to cultivate a group of welding robot operation and maintenance talents with professional skills to meet market demand.

VI. Digital production balance: laser power and acceleration

A. The key role of laser power and acceleration in digital production

Digital production requires balancing laser power and acceleration. Reasonable adjustment of these two parameters can ensure product quality and accuracy while improving production efficiency.

First, let’s understand the role of laser power in digital production. Laser power is a core parameter in laser cutting, welding and other processes. It directly affects the processing speed and processing effect. Increasing laser power can improve production efficiency and shorten processing time to a certain extent. However, excessive laser power can cause serious material ablation and affect product quality and accuracy. Therefore, in digital production, we need to reasonably adjust the laser power according to material characteristics, processing requirements and other conditions to improve production efficiency while ensuring product quality.

Secondly, acceleration also plays an important role in digital production. Acceleration refers to the speed of movement of equipment, tools or products during a production process. On the premise of ensuring product quality and accuracy, increasing acceleration can significantly improve production efficiency. However, excessive acceleration may cause vibration, jitter and other phenomena, affecting product processing accuracy. Therefore, in the digital production process, we need to increase acceleration while ensuring that product quality and accuracy are not affected.

B. How to balance laser power and acceleration to improve production efficiency

In order to achieve balanced adjustment of laser power and acceleration, advanced control systems, sensor technologies and intelligent algorithms need to be used in the digital production process. These technologies can monitor various changes in the production process in real time and automatically adjust according to preset parameters and models to ensure that laser power and acceleration are always in the optimal state. In addition, through the collection and analysis of large amounts of data, we can continuously optimize production parameters and further improve production efficiency and product quality. These technologies play an important role in the production process. They can monitor various changes in real time, automatically adjust according to preset parameters and models, and ensure that laser power and acceleration are always at their best. Advanced control systems are at the heart of the digital production process. By monitoring all aspects of the production process in real time, the control system can quickly detect and resolve imbalances in laser power and acceleration. This control system is highly flexible and reliable and can be adjusted according to production needs and actual conditions to optimize the production process. Sensor technology plays an important role in digital production. The sensor can collect key data in the production process in real time, such as laser power, acceleration, etc., and transmit these data to the control system for processing. Through sensor technology, we can understand the production status in time and ensure the safety and stability of the production process. In addition, intelligent algorithms are also the key to achieving balanced adjustment of laser power and acceleration. Intelligent algorithms can analyze and process the massive data collected, and automatically adjust laser power and acceleration according to preset models and targets. This makes the production process more

VII. Conclusion

A. Laser cutting machines play a key role in green manufacturing

As the core technology of green manufacturing, laser cutting machines improve production efficiency while reducing the impact on the environment, becoming a key driving force for the sustainable development of the manufacturing industry.

Laser cutting machines, as the core technology in the field of green manufacturing, have played an increasingly important role in my country's manufacturing industry in recent years. While production efficiency continues to improve, it effectively reduces the impact on the environment and injects strong impetus into the sustainable development of the manufacturing industry. The continuous innovation and advancement of laser cutting technology provides strong support for the sustainable development of the manufacturing industry. With technological breakthroughs, laser cutting machines have been successfully used in many fields, such as metal processing, advertising production, electronic device manufacturing, etc. This enables the manufacturing industry to improve production efficiency and reduce costs while also meeting the market's demand for personalized and diversified products, further promoting the green development of the manufacturing industry.

B.Environmental protection and efficiency are indispensable in modern manufacturing

Entering the era of Industry 4.0, environmental protection and high efficiency and high productivity in manufacturing have become the main goals, and the combination with artificial intelligence is driving the rapid development of modern manufacturing. The earth's resources are limited. The theme of environmental protection is not only an environmental need, but also an important issue in every industry today. In the rapidly developing contemporary society, the requirements for high efficiency are also increasing day by day. Therefore, the production and application of laser cutting machines can also reflect that environmental protection and efficiency have an irreplaceable position in the current modern manufacturing industry and today's society.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)