The difference between ordinary press brake and electro-hydraulic servo press brake

Ordinary press brake is a common equipment in industrial manufacturing, mainly used to bend metal sheets to achieve the desired shape and angle. Its working principle is based on a mechanical or hydraulic system, and a simple control mechanism drives the mold to apply pressure to the sheet to achieve bending. The structure of ordinary press brake is relatively simple, the operation is relatively convenient, and the cost is low, but there are certain limitations in terms of accuracy, efficiency and flexibility, and it is difficult to meet the processing requirements of high-precision and complex parts. Difficult.

Electro-hydraulic servo press brake is an advanced mechanical equipment that accurately controls the bending movement through an electro-hydraulic servo control system, and is mainly used for bending and forming of metal sheets. The equipment integrates electrical and hydraulic technologies, and realizes high-precision, high-efficiency and high-flexibility bending through the precise control of servo motors and hydraulic systems. The electro-hydraulic servo press brake has high-precision control functions, can quickly complete complex bending work, is suitable for manufacturing and processing a variety of complex parts, and meets the needs of high variety and small batch production.

There are large differences between ordinary press brakes and electro-hydraulic servo press brakes in terms of control systems, accuracy, efficiency, etc. Ordinary press brakes mainly rely on mechanical and hydraulic systems, and realize bending movement through manual control, with low control accuracy. The electro-hydraulic servo press brake adopts an electro-hydraulic servo control system. Through automatic control and programming, it can achieve high-precision bending operations, greatly improving production efficiency and processing flexibility. In contrast, the electro-hydraulic servo press brake has a high degree of automation and strong flexibility. It can quickly adjust bending parameters and replace molds, which can greatly improve production efficiency and processing quality.

Basic structure of press brake

- Frame: The main structure that carries the machine.

- Slider: Driven by the electro-hydraulic servo system, used to apply bending force.

- Workbench: The area where the workpiece is placed.

- Hydraulic system: Provides power source, including oil pumps, cylinders, and hydraulic pipelines.

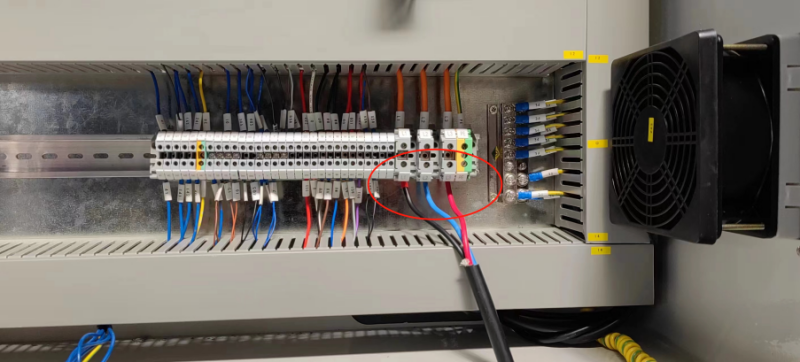

- Electrical control system: The core of controlling the entire bending process, including CNC systems and various sensors.

Working principle of press brake

- Preparation stage: Place the metal sheet to be processed on the workbench and adjust the mold according to processing requirements.

- Setting parameters: Set parameters such as bending angle, bending position, and pressure through the CNC system.

- Execute bending: Start the machine, and the electro-hydraulic servo system drives the slider to bend according to the preset parameters.

- Detection and adjustment: Use sensors to detect the bending effect and make necessary adjustments to ensure accuracy.

Refueling and wiring

- Add no less than 2/3 of anti-wear hydraulic oil to the oil tank to ensure system lubrication.

- Correctly connect the cable, connect to the 3-phase power supply, and ground the wire to ensure the safety of the equipment.

- Turn on the main power switch, wait for the equipment to be fully powered on, check the forward and reverse rotation of the motor, and ensure that the direction of motor rotation is the same as the arrow direction.

Daily startup steps

- Turn on the machine power switch and wait for full startup.

- Release the emergency stop switch, turn on the light, start the oil pump and find the origin.

- Test the operation of the X-axis and V-axis, and check whether the mold parameters correspond to the actual ones.

CNC programming and bending operation

CNC programming

- Enter the password to enter the programming interface, enter the programming name, plate thickness, mold selection, plate length, bending angle and other parameters.

- Enter the step length, check other step data, and prepare to start the program.

Bending workpiece

- Place the sheet close to the stopper and press the pedal to perform the bending operation.

- Complete the bending of each step in sequence to ensure the quality of the workpiece.

Measurement and calibration

- Place the sheet close to the stopper and press the pedal to perform the bending operation.

- Complete the bending of each step in sequence to ensure the quality of the workpiece.

Enter the correction parameters and check

- Enter the corresponding correction parameters according to the measurement results.

- Put the plate again to check to ensure that the bending angle is correct.

- Measure again, check that the angle is correct, and complete the calibration

- Image programming and 3D image programming (DA-69T only)

Image programming

- Add a new product and enter product information.

- Use the graphic programming function to program, select the mold and perform graphic simulation.

- 3D image programming (DA-69T only)

- Use the 3D image programming function to program more complex products.

Offline software operation

- Use offline software for programming and data management to improve programming efficiency.

- Shutdown steps

- Stop the program and oil pump

- Press the pedal switch to stop the upper mold against the lower mold.

- Stop the program and stop the oil pump.

- Turn off the equipment

- Press the emergency stop button and turn off the main power switch.

CNC programming and bending operation

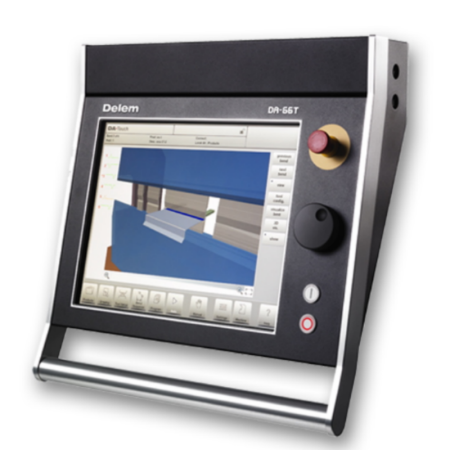

DA-66T CNC system

DA-66T is a high-performance CNC system for press brakes, which provides powerful programming and control capabilities and is suitable for various complex bending tasks.

Main features

- Multi-axis control: supports synchronous control of up to 8 axes, adapting to various complex bending requirements.

- Graphic programming: supports 2D and 3D graphic programming, and users can intuitively design and modify programs through the graphical interface.

- Touch screen operation: equipped with a 15-inch high-resolution touch screen, the operation is simple and intuitive.

- Intelligent optimization: with automatic bending sequence calculation and collision detection functions to ensure safe and efficient operation.

Usage process

- Initialization settings: Start the CNC system and perform basic initialization settings, including calibration of the machine origin.

- Program writing: Through the graphical programming interface, enter the geometric information and bending requirements of the workpiece, and the system will automatically generate a bending program.

- Parameter adjustment: adjust parameters such as bending force, speed and position according to specific processing requirements.

- Execute processing: Start the processing program, and the system will automatically control the bending process.

- Result detection: After processing, use sensors or manual detection of workpiece quality to ensure that it meets the design requirements.

DA-69T CNC system

DA-69T is another high-end CNC system launched by Delem. Compared with DA-66T, it is more comprehensive in function and suitable for more complex bending tasks.

Main features

- Full graphic 3D programming: Supports full 3D programming and simulation. Users can perform complex bending designs through a 3D graphical interface.

- Advanced algorithm: It has more efficient bending sequence calculation and collision detection algorithms to optimize production efficiency.

- Multi-machine coordination: Supports multi-machine networking and coordinated work, suitable for large-scale production environments.

- Remote monitoring and maintenance: Supports remote monitoring and maintenance functions, which facilitates users to monitor equipment status in real time and troubleshoot.

Usage process

- System startup: Start the CNC system and perform basic initialization operations.

- 3D modeling: Through the 3D programming interface, create a three-dimensional model of the workpiece and set the bending path and sequence.

- Parameter setting: Adjust specific processing parameters, such as bending angle, pressure, etc.

- Simulation and optimization: Through the simulation function of the system, check the entire bending process and optimize the bending sequence and path.

- Execute processing: Start the bending program, and the system automatically controls the machine for processing.

- Quality inspection: After the processing is completed, use the system's own inspection function or external inspection equipment to ensure product quality.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.