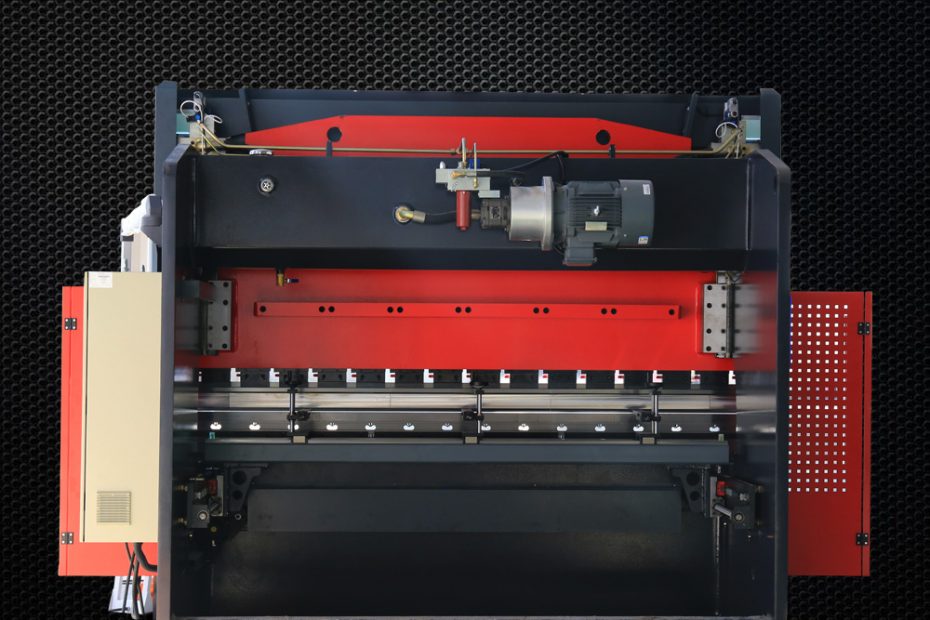

Electro-hydraulic bending machine by servo motor as the actuating device, by the numerical control system combined with grating

ruler feedback data control on both sides of the main cylinder flow ratio to achieve synchronized slider movement of a bending machine.

Electro-hydraulic servo bending machine: the main cylinders on both sides synchronously adopt proportional electro-hydraulic servo valve and other hydraulic control system and grating ruler to form closed-loop control, respectively limited by CNC independently.

Feedback accurate data to ensure the slider operation accuracy.

CNC bending machine and ordinary bending machine are made of stainless steel, ordinary steel plate and other plate processing;

The difference is whether there is computer control, whether there is automatic feedback.

The result is: processing speed, processing accuracy is different, processing efficiency is different;

Now the new customers to buy bending machine, generally buy NUMERICAL control, because the same processing a batch of plate,

ordinary machine two days to finish processing, and NUMERICAL control machine half a day can be done, the accuracy is higher.

Choose CNC bending machine, should consider many factors. Here are some tips that I hope will help you.

Workpiece, an important consideration is the parts you want to produce, the point is to buy a machine that can

complete the processing task and the workbench is short, the tonnage is very small. Carefully consider the material grade and large machining thickness and length.