DP-EP SERIES

All-Electric Press Brake

The EP Series Press Brake operates without hydraulic oil and is driven by an electric cylinder, eliminating hydraulic pollution and maintaining machine precision.

The EP Series Press Brake operates without hydraulic oil and is driven by an electric cylinder, eliminating hydraulic pollution and maintaining machine precision.

Every part can ensure a long service life and reduce production costs.

Durmapress press brakes feature a robust mono-block frame made from high yield steel, ensuring enduring accuracy and reliability. Each frame is tempered and backed by a 15-year warranty.

Durmapress press brakes feature a robust mono-block frame made from high yield steel, ensuring enduring accuracy and reliability. Each frame is tempered and backed by a 15-year warranty.

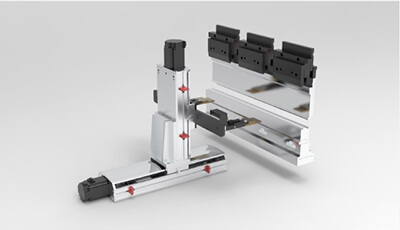

The stop finger in the DP-EP All-Electric Press Brake enhances the machine's accuracy, efficiency, and safety, making it an indispensable component for high-precision bending tasks.

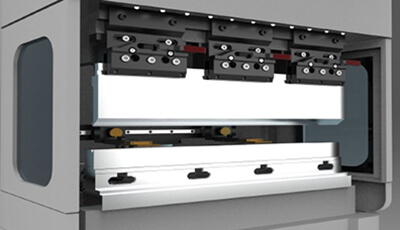

Our machines offer ample sheet metal space to prevent interference, enabling the production of complex parts. The large slider stroke and adjustable upper die (180 mm-210 mm) cater to various models.

The crossbeam is processed with high-quality carbon steel, and the overall structural design is simple, compact, and stable, resulting in fast speed and high accuracy. The standard configuration forthe rear material blocking ofthis machine is X and Y axes, with 2 adjustable blocking fingers.

The machine features high-speed lifting and stable accuracy through servo motor-driven screw. With imported C5-grade components and a 0.005mm Y-axis movement setting, it ensures precision, stability, and durability for efficient production.

The back gauge features a lightweight, strong aluminum alloy module and Taiwan Hiwin linear guide rail for smooth movement. With an accuracy of 0.01 mm, it ensures stable precision for both complex and high-tolerance production.

Advanced LED technology is used to create work area lighting, zero heat radiation, creating a comfortable environment for operators, greatly improving work efficiency, and opening up a new experience of efficient work.

The fully automatic lubrication system intelligently adjusts oil delivery based on operational needs, ensuring optimal lubrication for machine parts. This enhances equipment lifespan and boosts production efficiency.

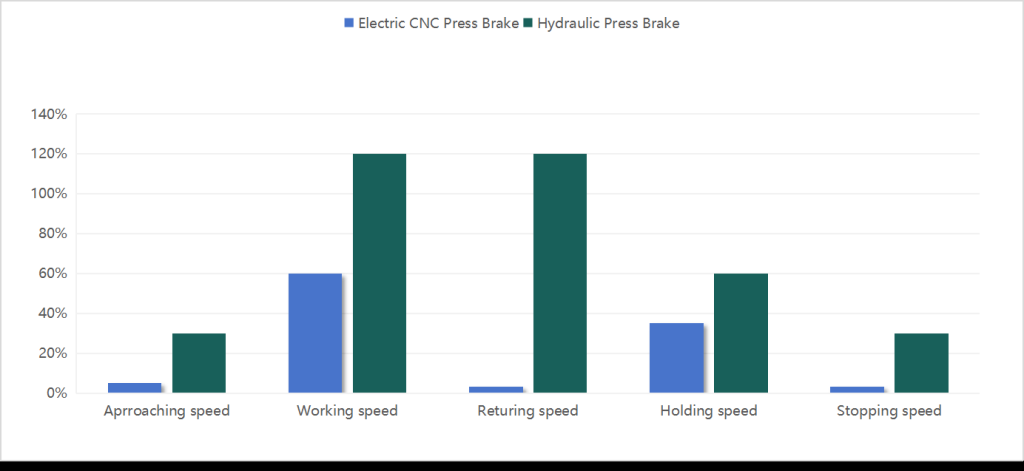

Screw guide rails are C5 grade for precise movement, with a minimum Y-axis setting unit of 0.005mm. The fully electric servo bending machine is exceptionally energy-efficient, consuming less than 0.5KW of electricity when idle.

One month's electricity consumption is 1/4 of that of a regular hydraulic bending machine.

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

7/24

Fill in the information below to receive a free quote and product brochure. We will respond within 24 hours!