What is punching force?

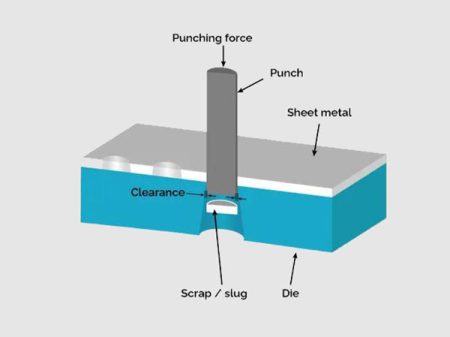

Blanking force refers to the maximum resistance of the material to the mold during punching. There are many reasons that affect the punching force at work, but the two main reasons that have a great influence on the punching force are the shear strength and tensile strength of the material. The harder the material, the greater the punching force.

Why should we calculate the punching force?

The purpose of calculating the punching force is to reasonably select the punch machine and design the mold. The tonnage of the punch press must be greater than the calculated punching force to adapt to the punching requirements. Each part of the mold must be able to withstand the force during blanking without deformation and breakage.

Calculation method of punching force

To calculate punching force:

Find the shear strength of the workpiece.

Multiply the shear strength by the thickness of the workpiece.

Multiply the product with the perimeter of the hole to obtain the punch force required to produce the hole.

If you are making a round, square or other hole in a given thickness of metal, you must know the force required to make the hole in the steel. The required punching tonnage can be calculated with the help of the following punching force calculation formula (blanking force formula):

F=K*L*t*τ

F: Blanking force

K: Safety factor; safety factor set by taking into account the wear of the cutting edge of the punching die, fluctuations in the gap between the punch and the die (changes in values or uneven distribution), lubrication conditions, changes in material mechanical properties and thickness tolerances, etc. Coefficient, generally 1.3

L——Total length of punching perimeter, mm

t—material thickness, mm

τ——Material shear strength, MPa

When the shear strength τ cannot be found, the tensile strength σb can be used instead of τ. In this case, the approximate calculation method of K=1 is used for calculation. Right now

F rush=Ltσb

In the formula, σb:tensile strength of material, MPa.

Application of punching force

Manufacturing process control

In the product design stage, the strength and durability of the material can be evaluated by calculating the blanking force, thereby selecting appropriate materials and process parameters. At the same time, the part structure and processing technology can also be optimized to improve product quality and production efficiency.

Material research

Blanking force is an important parameter for studying material deformation and failure behavior. By testing and analyzing the punching force of different materials under different conditions, we can gain an in-depth understanding of the material's mechanical properties and deformation mechanism, and provide a reference for the development of new materials.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.