Introduction to Hydraulic Rolling Machines

Overview of the role and application areas of Hydraulic Rolling Machiness

In the field of metal processing, Hydraulic Rolling Machiness have become indispensable due to their unique working principle and wide range of applications. Whether it is steel bending in the construction industry, or automotive and shipbuilding plate shaping, Hydraulic Rolling Machiness play a pivotal role. In this paper, the role of the Hydraulic Rolling Machines, application areas and the basic classification of the overview, and focus on 3-roll and 4-roll Hydraulic Rolling Machines features and its comparative analysis!

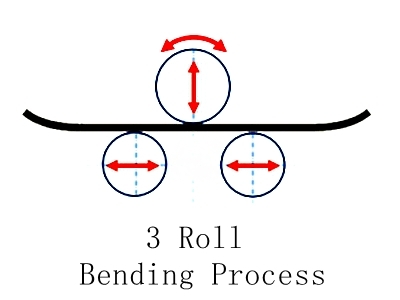

Basic classification:3-roll and 4-Hydraulic Rolling Machines

Hydraulic Rolling Machines is a key equipment in the field of metal processing, widely used in a variety of metal materials bending process. According to the different structure, Hydraulic Rolling Machines is mainly divided into two types of 3-roll and 4-roll. Although these two types of Hydraulic Rolling Machines in the working principle has a certain degree of similarity, but in the structure, function and performance but show their unique characteristics.

Principle of operation

The working principle of the Hydraulic Rolling Machines is mainly based on the plastic deformation of the material and the rolling of the rollers. In the Hydraulic Rolling Machines, the metal plate is placed between the rollers, through the rotation of the rollers and the application of a certain amount of pressure, so that the plate between the rollers to produce continuous bending deformation. The rotation direction and speed of the rollers can be adjusted as needed to realize the processing needs for different materials and different bending angles. At the same time, the Hydraulic Rolling Machines is also equipped with corresponding control system, which can precisely control the position, speed and pressure of the rollers, thus ensuring the processing accuracy and stability.

Process Overview

First, the operator places the sheet metal to be processed on the table of the Hydraulic Rolling Machines and adjusts the position and angle of the rollers according to the radius, angle and shape of the required bend. This step is critical as it determines the shape and accuracy of the final bend in the sheet.

Next, themachine is started and the rollers begin to move in the preset direction and speed of rotation. Under the action of the rollers, the plate begins to be subjected to pressure and friction, and gradually undergoes bending deformation. The contact between the rollers and the plate is continuous, so the plate can realize smooth and uniform bending.

In the bending process, the control system of the Hydraulic Rolling Machines plays a key role. It monitors the bending state of the plate in real time, including the bending angle, radius of curvature and other parameters, and makes real-time adjustments based on these data. For example, if the bending angle of the plate is detected to be too large or too small, the control system will automatically adjust the position or pressure of the rollers to correct the deviation and ensure processing accuracy.

In addition, Hydraulic Rolling Machiness are usually equipped with safety protection devices, such as overload protection and emergency stop, to ensure the safety of personnel and equipment during processing. These devices are able to respond quickly in the event of an abnormal situation and prevent accidents from occurring.

When the plate has completed the required bending process, the roll bender will automatically stop working. At this point, the operator can remove the processed sheet for subsequent processing or inspection. If you need to continue processing other plates, just repeat the above steps.

Overview of Components, Structural Features, Standard Equipment, and Optional Accessories of Hydraulic Rolling Machines

Main Components and Structure of Hydraulic Rolling Machines

Drive Unit: The core part of the rolling machine, providing power to drive the roll shafts. Typically consists of an electric motor, gearbox, and couplings.

Roll Shafts: One of the most crucial components, made up of multiple cylindrical rolls used to support and bend the sheet metal. Rolls are usually made of high-strength steel or cast iron.

Transmission Device: Transfers the low-speed rotation from the drive unit to the roll shafts. Typically consists of chains, gears, and belts.

Support Frame: The foundational structure of the rolling machine, bearing the weight of the entire equipment and providing a stable working platform.

Control System: Used to monitor and adjust the working status of the rolling machine, including electrical control boxes, sensors, and variable frequency drives.

Additionally, the rolling machine includes auxiliary mechanisms such as flipping and feeding auxiliary facilities, used for unloading and balancing workpieces.

Standard Features

- Cone bending device

- Induction hardened rolls

- Digital display for side rolls

- Fully welded steel (St-52) construction body

- Separate moving control panel

- Two rolling speeds

- Electro-hydraulic calibration

- All rolls are mounted in roller spherical roller bearings

- Safety equipment around the machine

- Central rolls are driven by hydraulic motors and planetary gearboxes

- CE, ISO9001–2008, TSEK, and TURQUM certified machine

Optional Features

- Central and side supports

- Variable speed of rotation

- Material feeding table with various features

- Interchangeable top roll

- Oil cooling system

- Driven side rolls

- Automatic material ejection equipment

- Automatic loading and unloading system

- Deflection compensating system

- Motors in variable voltage and frequency

- CNC

- NC

3-roll Hydraulic Rolling Machines features

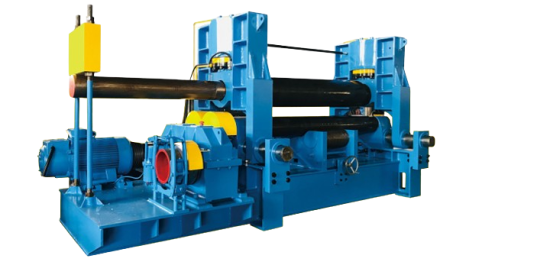

Shape Appearance

3-Hydraulic Rolling Machines usually adopts a compact and sturdy design, simple and generous appearance. Its overall frame is usually made of high-strength steel to ensure the stability and durability of the machine. The exterior color of the machine is usually industrial grey or blue to match the general aesthetic standard of industrial equipment. In addition, in order to facilitate operation and maintenance, the control panel of the 3-roll Hydraulic Rolling Machines is usually designed to be intuitive and easy to understand, with a reasonable layout of operating buttons and indicators, enabling the operator to quickly get started and accurately grasp the machine's operating status.

Machine structure

3-Hydraulic Rolling Machines machine structure mainly consists of three rollers, respectively, two fixed rollers and an adjustable roller. The fixed rollers are used to support the entry and exit of the plate, while the adjustable rollers can be adjusted to achieve the bending of the plate by adjusting its position and angle. The rollers are usually made of wear-resistant and heat-resistant materials to ensure that good performance and accuracy can still be maintained under long-time and high-intensity working conditions. In addition, the 3-Roll Hydraulic Rolling Machines is equipped with auxiliary components such as transmission system, lubrication system and electrical control system to ensure the stable operation and efficient processing of the machine.

Classification

According to different classification criteria, 3-roll Hydraulic Rolling Machines can be divided into various types. According to the degree of automation, can be divided into manual, semi-automatic and fully automatic three types. Manual 3-Hydraulic Rolling Machines requires the operator to manually adjust the position and angle of the rollers, suitable for small quantities, low precision requirements of the processing scenario; semi-automatic type is equipped with some automation functions, such as automatic adjustment of the roller position, etc., to improve the processing efficiency and accuracy; fully automatic type to achieve a fully automated operation, able to continuously and efficiently process a large number of plates, suitable for large-scale production lines.

In addition, according to the different materials processed, 3-roll Hydraulic Rolling Machines can also be divided into ordinary type, heavy duty and ultra-heavy duty and other types. Ordinary type is suitable for processing the general thickness of the metal plate; heavy and ultra-heavy with stronger processing capacity and higher precision requirements, to cope with thicker and harder material processing needs.

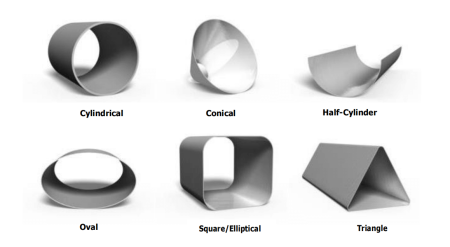

This machine offers a useful length of 1000mm to 10000mm and a thickness range from 2mm to 200mm. It features a cone bending device for easy conical bends, can handle shapes like O, U, R, and more. With special bending craft and high-accuracy pre-bending, it offers simple digital control. The drum-shaped top roller ensures perfect cylinders from thin to thick plates, with a support roller for stability. Customers can choose between an economic digital display or TNC digital control type. CE certificate included.

This kind of plate bending machine belongs to 3 roller symmetrical mechanical structure.The top roller moves up and down at the central part of the two bottom rolls.Screw nut and worm gear both play role of transmission.Two bottom rolls act as main driving rolls.Through the meshing,they are able to rotate between the output gear of the gearbox and the bottom roller,so as to supply the torque to bend plate.This type of machine does well in compact structure,easy operation and convenient maintenance.

This W11F plate rolling machine offers a useful length ranging from 1000mm to 2500mm, with a valid thickness range from 2mm to 6mm. Designed with user-friendliness in mind, it features asymmetrical solid rolls and an easy initial pinch operation. This makes it particularly suitable for thinner plates, providing convenient and efficient rolling processes.

This machine offers a useful length from 1000mm to 6000mm and a thickness range of 2 to 100mm. With the ability to bend plates on both sides without return, it features four rolls for efficient and precise bending operations. Complete with PLC for full automatic control and certifications including CE and ISO9001, it ensures quality results and ease of operation for various bending needs.

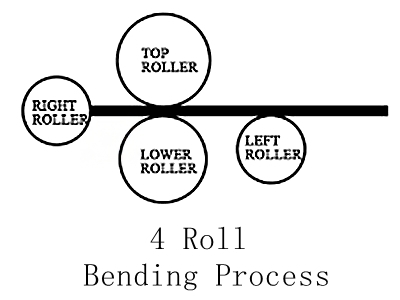

Features of 4-Roll Hydraulic Rolling Machines

Shape Appearance

4-Roll Hydraulic Rolling Machines is usually presented as a compact and sturdy body design, the appearance of smooth lines, the overall structure is stable. Its appearance color is usually adopted industrial standard color, such as dark gray or blue, which is not only beautiful and generous, but also easy to identify in the factory environment. In addition, the control panel is well laid out, with clear and easy-to-understand operation buttons and displays, making it easy for the operator to grasp the machine's operating status.

Machine Structure

The 4-Roll Hydraulic Rolling Machines consists of four rollers, including two fixed rollers and two adjustable rollers. This structure enables the machine to provide more stable and even support during processing, thus ensuring the bending precision and quality of the plates. At the same time, the rollers are made of high-strength, wear-resistant materials that can withstand high loads and long hours of operation, ensuring the machine's long durability.

Hydraulic control system and its advantages

The 4-Roll Hydraulic Rolling Machines adopts an advanced hydraulic control system, which realizes the precise adjustment of the rollers through the advancement of hydraulic cylinders. This system is characterized by fast response speed and high control accuracy, which ensures the precise position and angle of the rollers during the process. In addition, the hydraulic control system is equipped with overload protection and fault self-diagnosis function, which can stop the machine and prompt the fault information in time when there is an abnormality, so as to protect the safety of equipment and personnel.

High-precision processing and comfortable to use

Due to the 4-Roll Hydraulic Rolling Machines adopts precise hydraulic control system and high-quality roller material, it can realize high-precision bending processing of metal plates. Whether it is a simple straight line bending or complex curve bending, 4-Hydraulic Rolling Machines can easily cope with, and ensure that the processed product meets the design requirements.

4-Roll Hydraulic Rolling Machines in the design of the operator's comfort experience. Its control panel design is intuitive and easy to understand, easy to operate; at the same time, the machine runs with low noise, low vibration, providing a good working environment for the operator. In addition, some high-end models of 4-Hydraulic Rolling Machines is also equipped with intelligent human-machine interaction system, making the operation more convenient and efficient.

In summary, 4-Roll Hydraulic Rolling Machines with its unique shape appearance, machine structure, hydraulic control system and its advantages, as well as high-precision processing and comfortable to use, has occupied an important position in the metal processing industry. It can meet the needs of different customers, improve production efficiency, reduce production costs, and provide strong support for the development of enterprises.

Comparative analysis of 3-roll and 4-roll Hydraulic Rolling Machines

Structural differences and their impact on the work process

3-Roll Hydraulic Rolling Machines consists of the upper roller and two lower rollers, the structure is relatively simple. In the working process, the upper roll is driven by the transmission of the lower roll to rotate and realize the bending of the metal plate. This structure makes the 3-Hydraulic Rolling Machines in the processing of simple curves and conventional bending shape performance, operation is relatively simple, low cost.

The 4-Roll Machines in the structure of the addition of two side rolls, respectively, located in the upper roll and lower roll on both sides. This design allows the operator to more easily adjust the position of the sheet during forming, improving processing flexibility and precision. The addition of the side rolls also gives the 4-roll roll bender an advantage in processing complex curved surfaces, multi-radius bending and other technically difficult plates.

Function and performance comparison

Roll Hydraulic Rolling Machinesis mainly used to change the tension direction of the metal plate, to realize the processing of single curve and simple bending shape. It is easy to operate and relatively low cost, so it is widely used in enterprises that produce small quantities and many varieties. However, due to its structural limitations, the 3-Hydraulic Rolling Machinesmay not be able to cope with the demand for high-precision and complex shape processing.

4-Roll Hydraulic Rolling Machines, with their unique design and advanced performance, are capable of achieving more complex and precise sheet bending. They can process continuous bending shapes with multiple surfaces and radii, making them ideal for manufacturing products with intricate geometries. On the other hand, the 3-Roll Plate Bending Machine, while also capable of sheet bending, has relatively limited processing capabilities. It is mainly suitable for simple single-surface bending and faces challenges with complex shapes involving multiple surfaces and radii, resulting in lower precision and efficiency.

In contrast, the 4 Roll Rolling Machines is more outstanding in terms of function and performance. It can realize multi-curved surfaces, multi-radius, continuous bending and other technically difficult plate processing, and processing precision and high efficiency. This makes the 4-roll Hydraulic Rolling Machines in large-scale, high-precision, high-quality product processing advantage. However, its high price also makes some small and medium-sized enterprises are discouraged.

Application differences and selection considerations

3 - Hydraulic Rolling Machines because of its simplicity and practicality, mainly for small quantities, multi-species production environment, such as the construction industry, steel bending, processing of small metal products. These areas do not require high processing accuracy, but the cost and ease of operation have higher requirements.

The 4-roll Hydraulic Rolling Machines is more suitable for high-precision, large-scale production environment, such as automobile manufacturing, shipbuilding, precision machinery and other fields. These areas have higher requirements for the bending accuracy and shape complexity of the plate, need to 4-roll Hydraulic Rolling Machines high-precision processing capabilities to meet.

When choosing the type of Hydraulic Rolling Machines, enterprises should be based on their own production needs, processing accuracy requirements, budget and other factors for comprehensive consideration. For simple processing needs, limited budget for enterprises, 3-Hydraulic Rolling Machines is an economical choice; for the need for high-precision, high-complexity processing enterprises, should consider investing in 4-Hydraulic Rolling Machines.

3-Roll and 4-Roll Bending Machines Price Comparison

There are numerous models of plate bending machines, each with varying structural performance. Users looking to purchase a bending machine must fully comprehend the distinctions among these models to avoid making a misinformed purchase. Otherwise, the acquired bending machine might not meet your work requirements, fail to perform effectively, and potentially introduce difficulties to your work processes.

Within the same model category, the price of a three-roller plate bending machine is generally lower than that of a four-roller plate bending machine. This is due to the fact that the accuracy and efficiency of the three-roller plate bending machine are typically lower than those of the four-roller plate bending machine.

If the machine is not expected to be used frequently and the workpiece does not require high precision, opting for a lower-priced 3-roller plate rolling machine might be suitable. However, for products with higher precision requirements, it is highly recommended to invest in a 4-roller plate rolling machine with superior performance.

Conclusion

Through an in-depth comparative analysis of 3-roll and 4-roll Hydraulic Rolling Machines, we can clearly see the main differences between them and their respective advantages.

First of all, from the structural point of view, 3-Hydraulic Rolling Machines consists of three rollers, simple and compact structure, suitable for basic bending needs. While the 4-roller Hydraulic Rolling Machines adds side rollers, making the structure more complex, but this also provides the possibility of high-precision, complex shape processing.

Secondly, in terms of function and performance, 3-Hydraulic Rolling Machines is mainly used for simple bending operations, easy to operate, low cost, suitable for small quantities, multi-species production environment. While the 4-roll Hydraulic Rolling Machines is able to achieve high precision, high complexity processing, to meet the needs of large-scale, high-quality production, but the cost is relatively high.

Furthermore, from the application field, 3-Hydraulic Rolling Machines because of its simple and practical characteristics, in the construction, small metal products and other fields have a wide range of applications. The 4-Hydraulic Rolling Machines is more used in automotive, marine, precision machinery and other industries that require high-precision processing.

In summary, 3-roll and 4-roll Hydraulic Rolling Machines in the structure, function, performance and application areas have significant differences. Therefore, when choosing the type of Hydraulic Rolling Machines, we need to weigh the specific application scenarios. For simple bending needs and small-scale production, 3-Hydraulic Rolling Machines is an economical and practical choice; for the need for high-precision, high-complexity processing of large-scale production, 4-Hydraulic Rolling Machines is more appropriate.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.