Introduction

In modern industrial production, the press brake plays a crucial role in the field of metal processing as a key equipment. When discussing press brakes, two different types often come into play: the electric press brake and the hydraulic press brake. These two machine types have distinct differences in principles, performance, and applicable scenarios. Therefore, when choosing the appropriate press brake, it is necessary to carefully consider their respective characteristics and advantages.

Electric Press Brake

The electric press brake mainly relies on a mechanical transmission system driven by an electric motor to achieve the bending processing of metal sheets. Its working principle involves the electric motor driving gears and transmission rods, causing the upper and lower dies to move relative to each other, thereby bending the metal sheet. This type of press brake is typically suitable for the production of small batches or medium-sized parts, with relatively simple operation, easy control, and adjustment.

Hydraulic Press Brake

The hydraulic press brake, on the other hand, utilizes a hydraulic system to achieve the bending processing of metal sheets. The hydraulic system controls the movement of the piston through the pressure of hydraulic oil, thereby driving the upper and lower dies to bend the metal. This type of machine is usually suitable for bending large and thick sheets, possessing strong bending capabilities and stability.

Working Principle of Electric Press Brake

Motor Drive

The motor drive is one of the core components of modern industrial automation, playing an essential role across various industries. From simple household appliances to complex industrial production equipment, the motor drive is crucial. With the continuous progress of technology, motor drive technology has been developing and improving, bringing more efficient and stable production methods to various industries. The main function of the motor drive is to control parameters such as the motor's speed, direction, and torque, to achieve precise control of mechanical equipment. This requires the motor drive system to have high-performance control algorithms and precise sensor feedback to ensure stable operation of the motor in various working environments.

Transmission System

The transmission system is a critical part that transfers the power from the motor to the working mechanism of the press brake. In the electric press brake, the transmission system typically consists of gears, transmission rods, and connecting components. These components are precisely designed and manufactured to ensure efficient and stable power transmission. Through the engagement of gears and the rotation of transmission rods, the power from the motor is transferred to the upper and lower dies, causing them to move relative to each other and bend the metal sheet. Optimal design of the transmission system is essential for improving the bending accuracy and efficiency of the press brake.

Motion of Working Components

The working components of the electric press brake mainly include the upper and lower dies and the press beam. Driven by the motor, the transmission system moves the upper and lower dies in relative motion to achieve the bending of the metal sheet. The motion of the electric press brake can be linear or curvilinear, depending on the processing requirements. Linear motion is suitable for simple bending processes, while curvilinear motion can achieve more complex bending shapes. To meet different processing needs, the electric press brake is usually equipped with various dies and press beams to accommodate different sizes and shapes of metal sheets.

Working Principle of Hydraulic Press Brake

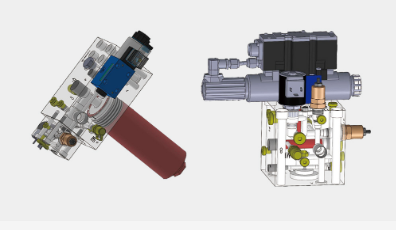

Hydraulic System

The hydraulic system is the core part of the hydraulic press brake, mainly composed of hydraulic pumps, control valves, cylinders, and oil tanks. The hydraulic pump is responsible for drawing hydraulic oil from the oil tank and, through control valves, adjusting pressure and flow to drive the piston of the cylinder for reciprocating motion. The movement of the piston in the cylinder drives the closing and opening of the upper and lower dies, thereby bending the metal sheet.

Motion of Cylinder and Piston

In the electric press brake, the cylinder is usually driven directly by the motor, and the piston moves up and down through motor transmission. In contrast, the hydraulic press brake controls the movement of the cylinder and piston through the hydraulic system, providing more stable and precise motion control.

Hydraulic Transmission and Control

The hydraulic press brake utilizes hydraulic transmission, offering advantages of high stability and fast response. The hydraulic system can control pressure and speed more precisely, making it suitable for situations where high precision of workpieces is required.

Performance Comparison of Electric Press Brake and Hydraulic Press Brake

Precision and Stability

Precision Characteristics of Electric Press Brake

The precision characteristics of an electric press brake, as an efficient and flexible processing equipment, largely depend on the performance of the electric motor and transmission system. The stability and precision of the electric motor provide reliable power support for the bending process, while the accuracy of the transmission system directly affects the operational precision of the press brake. However, compared to hydraulic press brakes, electric press brakes may slightly lag in precision. This is mainly because electric press brakes have certain limitations in dynamic response and pressure control, which may result in slight shortcomings when handling tasks with high precision requirements. Nevertheless, electric press brakes still enjoy widespread application in various fields due to their advantages such as efficiency, environmental friendliness, and ease of maintenance.

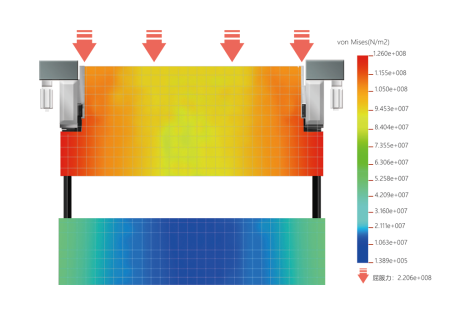

Stability Advantage of Hydraulic Press Brake

The hydraulic press brake has gained wide acclaim in the metal processing industry due to its powerful stability and precision. The advantage of the hydraulic system lies in its ability to provide continuous and stable power output, which is crucial for press brakes that need to work continuously for long periods. Additionally, when dealing with large and thick metal sheets, the hydraulic press brake's strong bending capability and stability give it an unparalleled advantage. The hydraulic system can precisely control motion by adjusting pressure and flow, allowing the hydraulic press brake to maintain extremely high stability when handling workpieces with high precision requirements.

Efficiency and Production Capacity

The electric press brake occupies a significant position in the metal processing industry with its flexible operating speed and high processing capacity. The transmission system driven by an electric motor enables quick start-up and stop of the bending process, greatly enhancing production efficiency. Additionally, electric press brakes are typically equipped with various dies and press beams, allowing them to quickly adapt to different sizes and shapes of metal sheets, further improving production efficiency. Although electric press brakes may have slight limitations when handling large and thick metal sheets, they have significant advantages in small batch or medium-sized part production due to their efficient operating speed and flexible processing capabilities.

Performance in Mass Production of Hydraulic Press Brake

The hydraulic press brake excels in handling large and thick metal sheets as well as mass production scenarios. The hydraulic system's ability to provide continuous, stable power output enables the hydraulic press brake to have stronger bending capabilities and stability when dealing with large and thick metal sheets. Additionally, hydraulic press brakes are typically equipped with automated control systems, allowing for continuous and efficient production. In mass production scenarios, the hydraulic press brake can maintain high production efficiency and product quality stability, meeting the demand for efficient production in enterprises.

Cost and Maintenance

Cost and Maintenance

Economic Efficiency and Maintenance Costs of Electric Press Brake

Electric press brakes generally have lower initial investment costs and lower maintenance costs. The relatively simple electric motor and transmission system lead to lower manufacturing and maintenance costs. Moreover, the operation and maintenance of electric press brakes are relatively simple and do not require complex hydraulic systems, further reducing maintenance costs. This makes electric press brakes a cost-effective choice for small and medium-sized enterprises.

Maintenance Requirements and Costs of Hydraulic Press Brake

Although hydraulic press brakes have higher production efficiency and stability, their maintenance costs are relatively high. The complexity of the hydraulic system requires more specialized maintenance and technical support. Additionally, the replacement and filtration of hydraulic oil are important parts of hydraulic press brake maintenance, requiring regular inspection and replacement. However, considering the advantages of hydraulic press brakes in processing large and thick metal sheets as well as in mass production, these maintenance costs are usually justified.

Applicable Scenarios of Electric Press Brake

Small-Scale Processing Workshops: Electric press brakes are suitable for small-scale processing workshops, especially those requiring frequent die changes and processing of different sizes and shapes of metal sheets. Due to their flexible operation, ease of maintenance, and low investment costs, electric press brakes are an ideal choice for many small enterprises. Moreover, electric press brakes can be combined with automation equipment to achieve automated production, further enhancing production efficiency.

Scenarios Requiring High Precision: Although electric press brakes may slightly lag behind hydraulic press brakes in terms of precision, they can still meet the requirements in many scenarios where high precision is needed. For example, in the processing of precision parts or products requiring consistent dimensions, electric press brakes can achieve high processing accuracy through precise transmission systems and control algorithms.

Applicable Scenarios of Hydraulic Press Brake

Large-Scale Sheet Metal Processing: Hydraulic press brakes have significant advantages when processing large and thick metal sheets, making them particularly suitable for the field of large-scale sheet metal processing. For example, in industries such as shipbuilding and bridge construction that require processing of large steel plates and profiles, hydraulic press brakes can provide powerful bending capabilities and stability to meet the processing needs.

Mass Production: Hydraulic press brakes perform excellently in mass production scenarios, suitable for enterprises requiring continuous and efficient production. For example, in industries such as automotive manufacturing and home appliance production, where a large number of metal sheet parts need to be bent, hydraulic press brakes with their efficient and stable production capabilities can meet the demand for output and product quality.

Automated Production Lines: Hydraulic press brakes can be combined with automation equipment to form automated production lines. Through integrated control systems and sensor technology, automated monitoring and adjustment of the bending process can be achieved, further improving production efficiency and product quality stability. This application of automated production lines is particularly suitable for enterprises with high requirements for production efficiency and product quality.

Conclusion and Recommendations

In conclusion, electric press brakes and hydraulic press brakes each have their unique advantages and disadvantages, suitable for different production requirements and application scenarios. Electric press brakes are favored for their efficiency, energy efficiency, ease of maintenance, and environmental friendliness, especially in scenarios requiring rapid die changes, high-precision control, and environmental considerations. However, electric press brakes may have limitations when handling large tonnage and high-strength materials.

Hydraulic press brakes are renowned for their powerful power output, wide applicability, and good adaptability to complex working environments. They are particularly suitable for scenarios requiring large tonnage, high loads, and high-precision control, such as the bending of large metal sheets. However, hydraulic press brakes also have their limitations, such as higher maintenance costs, high energy consumption, and potential environmental issues such as hydraulic oil leaks.

When choosing a press brake, enterprises should consider their specific production requirements and processing needs comprehensively. For companies pursuing efficiency, high precision, and environmental awareness, the electric press brake may be a better choice. For scenarios requiring handling of large, high-strength materials, and where cost and environmental requirements are not as strict, the hydraulic press brake may be more suitable.

In summary, when selecting a press brake, it is essential to consider not only its performance but also factors such as cost, applicable scenarios, and long-term maintenance. Only by considering these factors comprehensively can enterprises choose the press brake equipment that best suits their production needs.

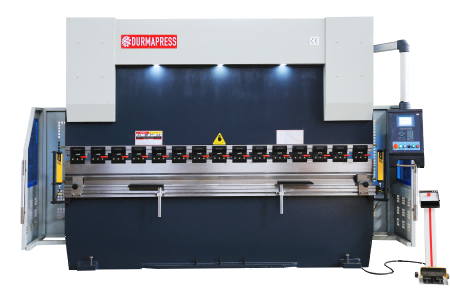

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)