Introduction

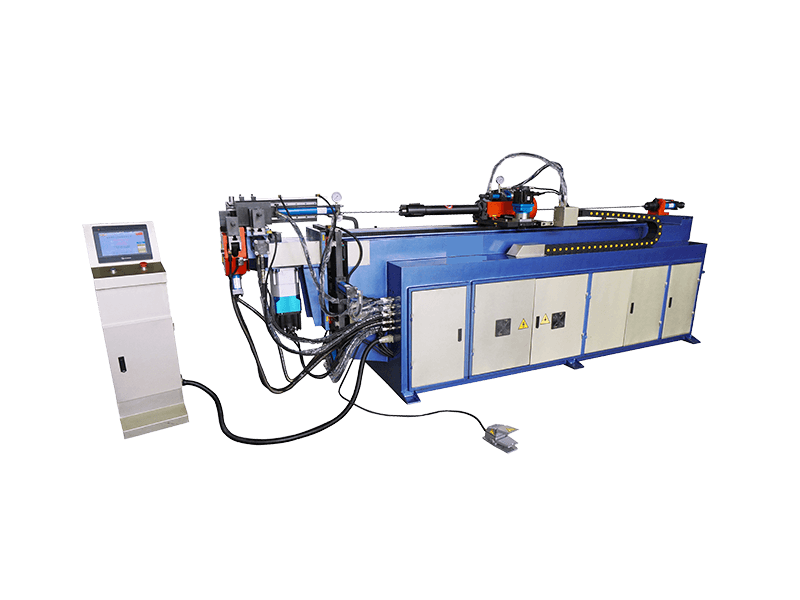

As one of the important equipment in the field of modern metal processing, automatic CNC tube bending machines are widely used in aerospace, automobile manufacturing, construction and other industries with their high-precision and high-efficiency tube bending capabilities. This article will introduce the basic structure and working principle of the automatic CNC tube bending machine, and deeply explore the functions and roles of its various key components.

Basic structure overview

The basic structure of the automatic CNC tube bending machine mainly includes the following aspects:

Control system

The control system is the core part of the tube bending machine, responsible for the operation of the entire equipment and the coordination of the work of each part. It includes CNC controllers and related software systems for programming, monitoring and controlling the entire tube bending process.

Servo drive system

The servo drive system achieves precise bending of the tube by precisely controlling the rotation of the servo motor. It includes components such as servo motors, encoders and drivers to ensure precise control of position and angle.

Mechanical transmission system

The mechanical transmission system transmits the rotational force of the motor to the tube bending mechanism through components such as transmission shafts and gear boxes to complete the tube bending operation. Key components include transmission shafts, gears, transmission belts, etc.

Die system

The die system is the working head part of the tube bending machine, which directly contacts and forms the bend of the tube. The design and selection of the die directly affect the accuracy and efficiency of the tube bending.

Introduction to working principle

The working principle of the automatic CNC tube bending machine can be briefly described as the following steps:

CNC programming and data input

The operator writes or inputs a pre-designed tube bending program through the CNC controller. The program includes parameters such as bending angle, bending radius, and tube feed.

Servo motor drive and position control

The control system accurately controls the position and speed of each axis through the servo drive system according to the programming instructions to ensure accurate control during the tube bending process.

Mechanical transmission and bending process

The servo motor transmits power through the mechanical transmission system to drive the die system to perform the tube bending operation. The control system monitors and adjusts the angle and position of the tube bending process in real time.

Common faults and cause analysis

During operation, the automatic CNC tube bending machine may encounter the following common faults:

Control system failure

- CNC system crash or freeze: may be caused by software problems or unstable power supply.

- Data transmission error: may be caused by signal interference or communication line failure.

Servo drive system failure

- Servo motor overheating or damage: may be caused by excessive load or cooling system failure.

- Encoder failure: may cause position control accuracy to decrease.

Mechanical transmission system failure

- Drive shaft wear or breakage: long-term use or excessive load may cause wear of transmission parts.

- Bearing damage: may be caused by insufficient lubrication or overload.

Mold system failure

- Mold wear or damage: long-term use or improper operation may cause mold failure.

- Inaccurate mold positioning: may cause bending angle deviation or quality problems.

Other common faults

- Power supply problem: unstable voltage or insufficient power supply may affect equipment stability.

- Cooling system failure: coolant pump failure or pipeline blockage may cause servo motor overheating.

- Lubrication system failure: lubricating oil pump failure or pipeline leakage may cause increased wear of mechanical parts.

Repair and maintenance measures

Restart CNC system

In the event of a freeze or system failure, first try to restart the CNC control system to ensure stable power supply and connection.

Check and replace damaged servo drives

Check the working status of the servo drives regularly. If damage or abnormality is found, replace them in time to ensure stable operation of the system.

Check data transmission lines and interfaces

Check the connectivity and interface status of data transmission lines regularly to prevent control problems caused by data transmission errors.

Check and replace servo motors

Perform regular inspection and maintenance on servo motors. If abnormal temperature or unstable operation is found, replace them in time to avoid further damage.

Replace encoders

The encoder is a key component to ensure position control accuracy. Check and replace it regularly to ensure system accuracy.

Check and repair drive circuits

Check the drive circuits regularly to ensure good circuit connection and avoid control abnormalities caused by circuit problems.

Mechanical transmission system maintenance

Replace drive shafts and bearings

Check the wear of drive shafts and bearings regularly, and replace them in time according to usage to ensure transmission efficiency and stability.

Repair or replace clutches

Check the working status of the clutch regularly to ensure its normal operation and avoid equipment downtime caused by clutch failure.

Regularly lubricate and maintain the transmission system

Use appropriate lubricants to lubricate the transmission system regularly to extend component life and reduce wear.

Mold system maintenance

Replace or repair worn molds

Check the wear of molds regularly, replace or repair them in time to ensure the quality and accuracy of pipe bending.

Adjust mold positioning accuracy

Calibrate and adjust the mold positioning system regularly to ensure accurate control of the position and angle of the pipe bending.

Check and reinforce the mold clamping device

Calibrate and adjust the mold positioning system regularly to ensure accurate control of the position and angle of the pipe bending.

Other repair and maintenance measures

- Check the power lines and switches regularly.

- Repair or replace cooling system components.

- Check and replace lubricating oil and filter elements regularly.

Measures to prevent failures

Perform equipment inspection and maintenance regularly

Develop a detailed equipment inspection plan, conduct comprehensive inspection and maintenance of the equipment regularly, and deal with problems in a timely manner.

Comply with equipment operating procedures and safety regulations

Operators must strictly comply with equipment operating procedures and safety operating regulations to reduce equipment failures caused by operating errors.

Use qualified raw materials and molds

Operators must strictly comply with equipment operating procedures and safety operating regulations to reduce equipment failures caused by operating errors.

Summary

Fault repair and maintenance of automatic CNC tube bending machines are the key to ensuring stable operation of equipment and production efficiency. Through regular inspections, timely maintenance and effective management, the occurrence of failures can be reduced, the life of equipment can be extended, and production efficiency and product quality can be improved. Keeping equipment in good condition and efficient operation not only affects production efficiency, but also affects the economic benefits and market competitiveness of enterprises. Enterprises should strengthen their attention to equipment management, increase maintenance investment, and establish a sound maintenance system to ensure long-term and stable operation of equipment. With the advancement of science and technology and the improvement of industry demand, the maintenance technology of automatic CNC tube bending machines is also constantly developing. In the future, it will be more intelligent and automated, improve fault diagnosis capabilities and maintenance efficiency, and provide users with more reliable support and services.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.