features

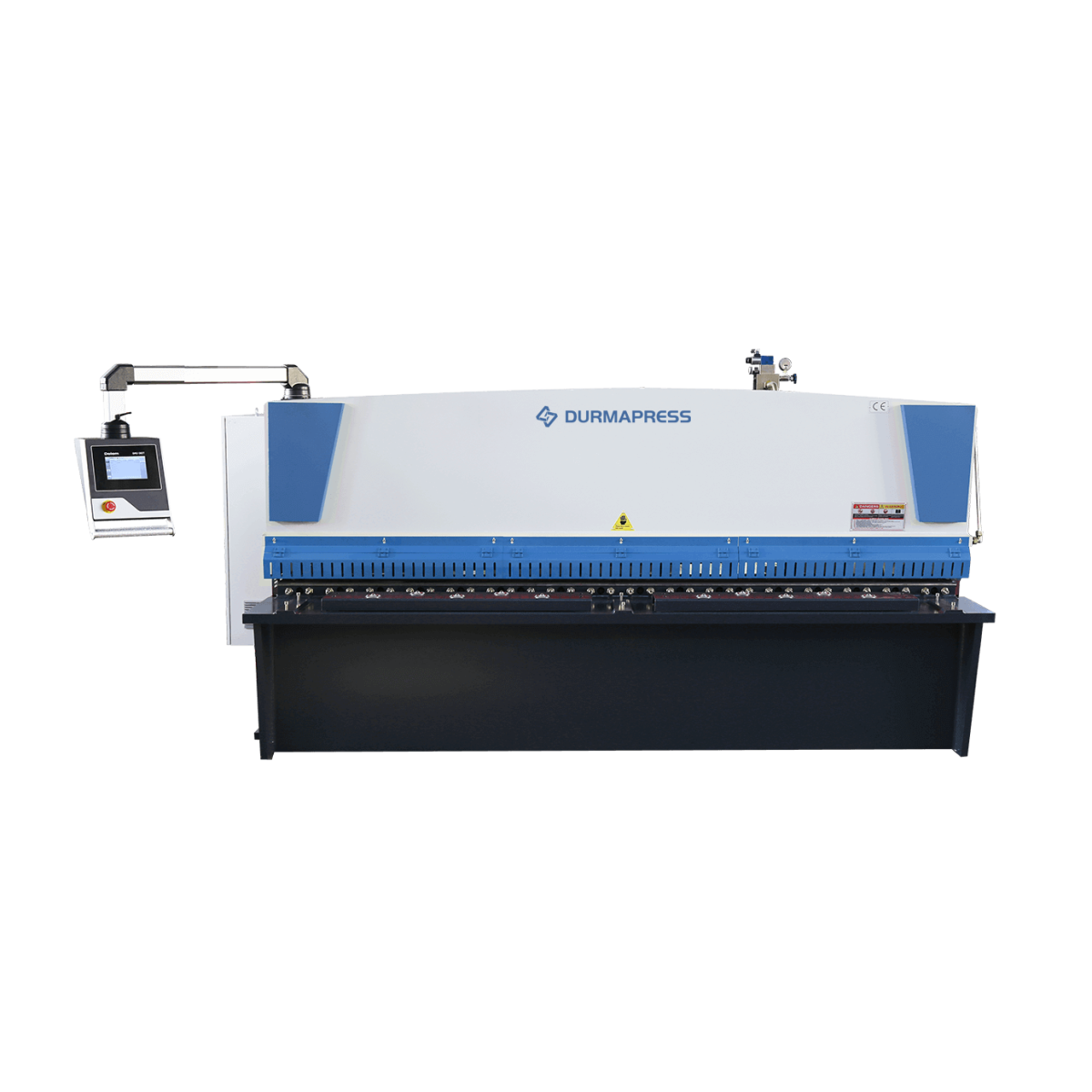

- Achieve quicker and superior-quality cuts.

- Robust and enduring machine framework.

- CNC-managed space and cutting angle adjustments.

- Minimized maintenance expenses.

- Exceptional precision with user-friendly controls.

- Enhanced safety measures.

- Dependable components from global renowned brands.

- Cost-effective cutting solutions.

Exporting country

0

+

Customer satisfaction Rate

0

/5

Professional team members

0

Standard Component

CNC Control System

DELEM DAC 310T

DAC-300 Touch shear control

- Panel based housing

- Bright LCD screen

- Back gauge control

- Retract function

- Cutting angle or gap control

- Stroke length limitation

- Manual movement of axes

- Stock count

STANDARD Component

Other Components

Every part can ensure a long service life and reduce production costs.

Machine Frame

Durmapress press brakes feature a robust mono-block frame made from high yield steel, ensuring enduring accuracy and reliability. Each frame is tempered and backed by a 15-year warranty.

Knife adjust

The knife adjust mechanism allows for precise adjustment of the blade clearance. Proper blade clearance ensures clean and accurate cuts, reduces wear on the blades, and prevents material deformation.

Ball Screw

Ball screws are used for converting rotational motion into linear motion with high precision and efficiency. In a shearing machine, they are typically employed in the back gauge system to ensure accurate positioning and movement of the material being cut.

motor

The motor provides the necessary power to operate the shearing machine. It drives the hydraulic system and other mechanical components, ensuring smooth and consistent operation.

Hydraulic Valve

Hydraulic valves control the flow and pressure of hydraulic fluid within the system. They regulate the movement of the blades and other hydraulic components, ensuring precise and controlled cutting actions.

Electrical System

The electrical system includes all the electronic components that control and monitor the shearing machine's operations. This system ensures coordinated and safe functioning of the machine, including the motor, sensors, and control panels.

Ball Integrated Front Tables

These tables are equipped with balls or rollers that facilitate easy and smooth movement of the material. They help in positioning the material accurately under the blade, reducing manual effort and improving cutting precision.

Press Cylinder

The press cylinder applies pressure to hold the material firmly in place during the cutting process. This prevents the material from moving or shifting, ensuring accurate and clean cuts.

from start to finish

Durmapress always adheres to the concept of putting customers first in the whole purchase experience, and continuously optimizes and innovates the production process to cater to the needs of all large, medium and small manufacturing companies.

- 20+ Years of Experience

- Personalized customized machines

- Perfect after-sales system

- 24/7 Availability

Why Choose our shearing machine?

1

Verified welded steel structures

Proven welded steel construction ensures a strong, precise, and easy-to-use body. The sturdy frame extends the service life and greatly saves production costs. Thousands of global customers already trust it.

2

Cutting capacity

Our machine can cut metal sheets from 6mm to 20mm thick and are available in standard lengths from 2m to 6m. In case of special needs, we also offer machines with higher cutting capabilities.

3

Global Component Brands

We source components from reliable and renowned brands worldwide, ensuring quality and reliability. Our shearing machines are built with top-notch materials and craftsmanship, ensuring durability and longevity.

durmapree factory

Watch the Video

Manufacturer of cutting-edge metal processing equipment

durmapress factory

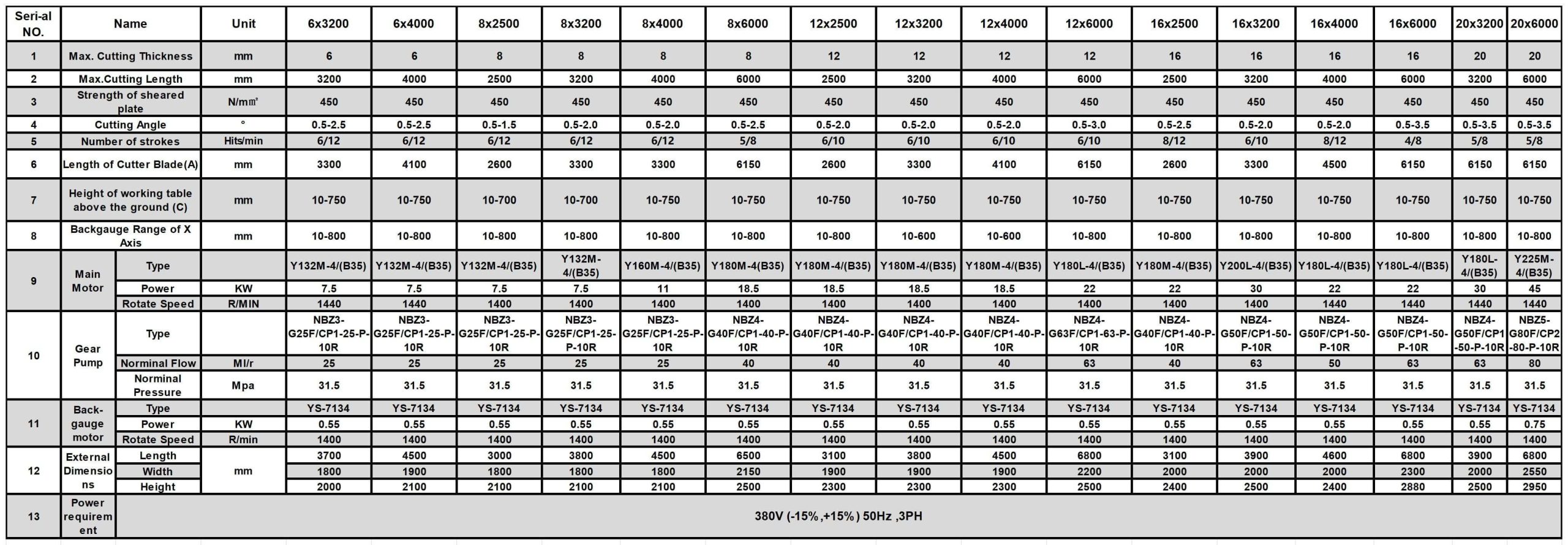

Product parameters

durmapress factory

Contact us

Location

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Our Hours

7/24

Follow Us