Step-by-Step Guide to Operating a CNC Punch

Operating a CNC punch involves a series of carefully executed steps to ensure safety and efficiency. First, before installing the mold, it is crucial to thoroughly inspect it. The mold should only be installed within the punch's travel stroke's allowable range, ensuring usage within the specified safety parameters. During equipment startup, begin by opening the compressed air valve (or oil pump) and then activate the friction wheel motor. When using friction pressure in forging with a CNC punch, blacksmiths must be adequately trained.

Safety Checks and Machine Operation

Pay close attention to the oil pump's pressure and air compression during normal operation to ensure everything is functioning correctly. Before running the machine, perform a strict check of the vertical head positioning device, ensure the mold is securely fastened, and verify the buffer's condition. It is not permissible to adjust the press or install the mold while the flywheel is in rotation. This precaution helps prevent accidents and equipment damage.

Finishing Up and Control Punch Positioning

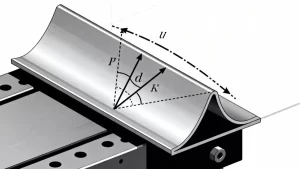

Once the work is finished, shut down the punch in the correct order, allowing it to fall smoothly. The position of the control punch largely depends on the size and shape of the holes in your processed products. Turret molds can be classified based on the mold's aperture size, making mold selection easier. These classifications include A (1/2" station), B (1 1/2" station), C (2" work position), D (3 1/2" station), and E (4 1/2" station), each with specific processing ranges. CNC punch dies can be configured according to product requirements, with stations available in 6, 12, 16, 18, 20, 24, and 32 configurations.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Follow Us

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.