Numerical control laser cutting is an ideal cutting means to improve the performance and industrialization of laser cutting machine,

so as to meet the growing market demand. CNC laser cutting machine is very suitable for today's development needs,

at the same time with high cost performance, after-sales auxiliary response and other characteristics, worthy of attention.

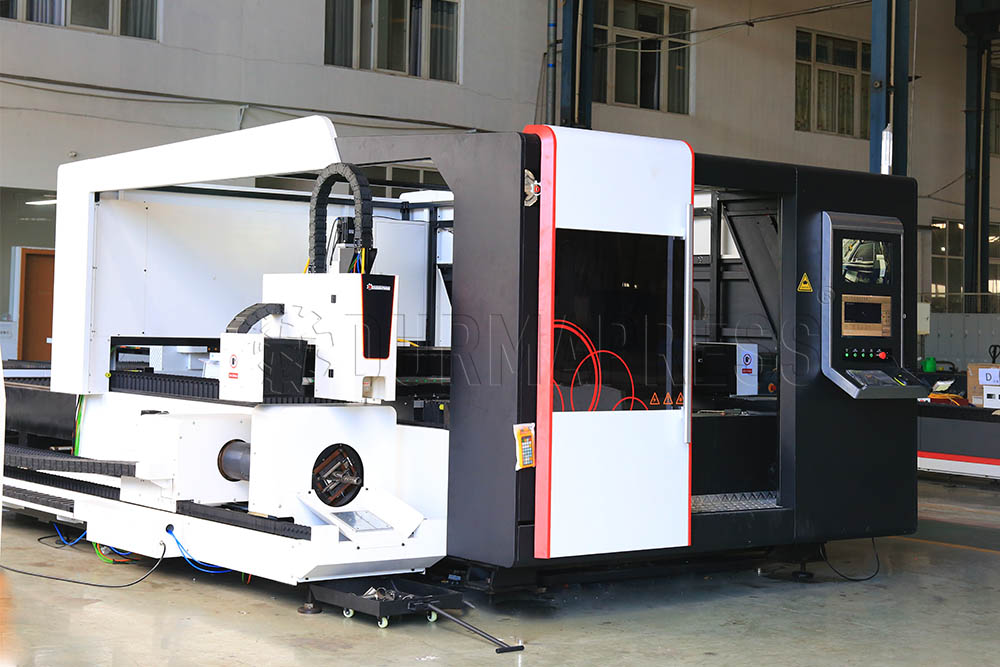

Laser cutting machine mechanical structure design: mainly reflected in the beam and machine tool structure design. The beam should be light and flexible in design, and the machine structure should have high rigidity and stability. These are the basic elements to achieve high precision laser cutting.

Laser cutting machine NUMERICAL control technology: this requires high quality control system. It should have laser control function, good machine tool motion control performance and remote diagnosis and control function under high speed operation.

High power laser beam transmission focusing technology: beam quality is the key to laser cutting quality, key technologies include: proprietary beam quality control, beam radius adjustment, beam waist compensation, video beam calibration system, etc.

Laser cutting machine proprietary technology: including edge monitoring, capacitance height tracking, cutting monitoring, penetration detection, etc.

Special CAD/CAM software system for laser cutting machine: in order to cooperate with the graphic conversion of laser cutting, the work of writing complex parts program becomes simple and smooth, and editing and modification is also very convenient. It is necessary to develop and design a special CAD/CAM software system.

High power laser cutting head design: laser cutting technology research, especially for curved surface cutting, titanium alloy cutting, thick plate cutting and other technology research.