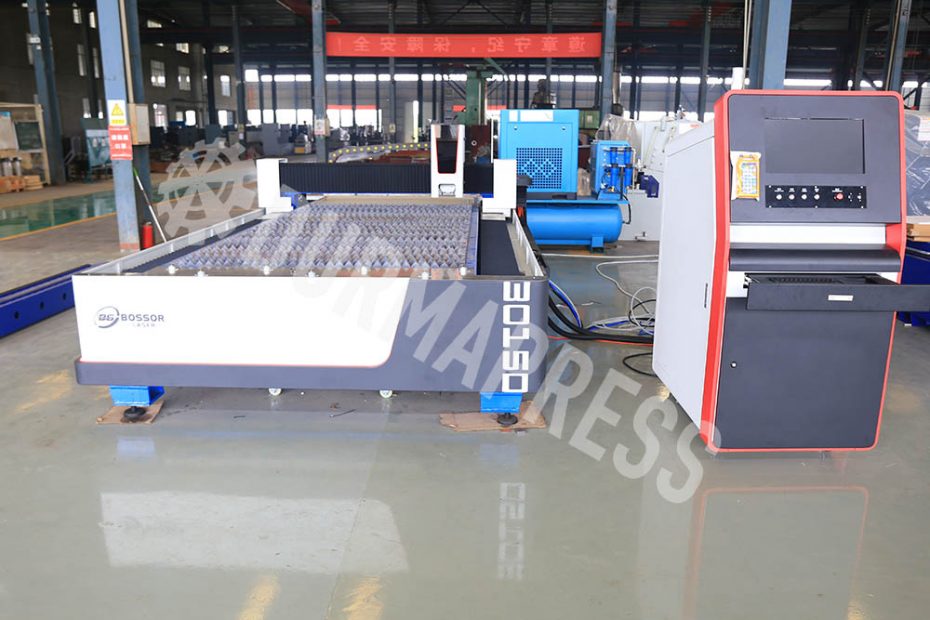

Classification of 100w fiber laser cutting machine

Classification of 100w fiber laser cutting machine: 1, cutting machine from the cutting material to distinguish, divided into metal material cutting machine and non-metal material cutting machine. 2. Non-metallic material cutting machine is divided into flame cutting machine, plasma cutting machine, laser cutting machine, water knife cutting machine, etc. 3, metal material cutting machine is mainly a tool cutting machine. 4, cutting machine from the control mode to distinguish, Maanshan cutting machine, divided into CNC cutting machine and manual cutting… Read More »Classification of 100w fiber laser cutting machine