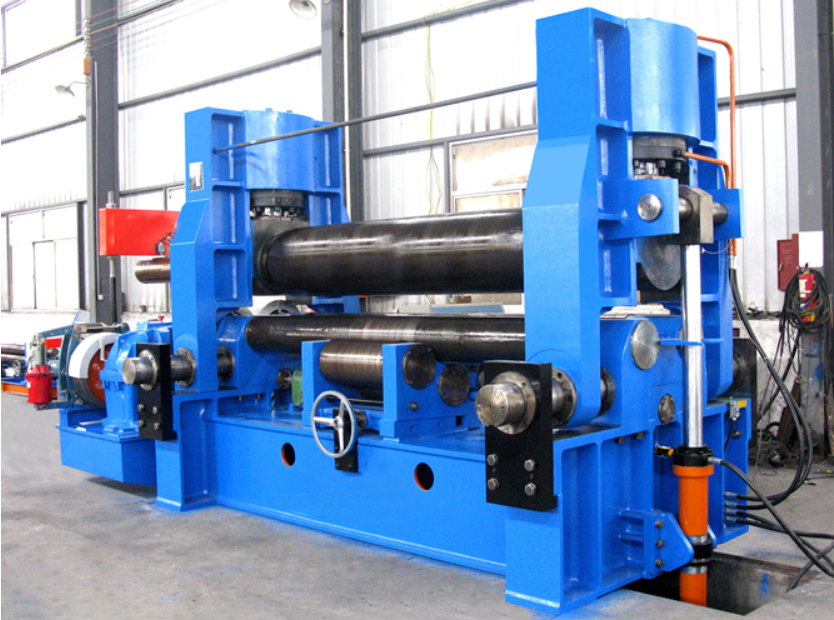

W11S upper roll universal plate winding machine

The main features of universal W11S plate winding machine: Super group products unique bending process precision, high precision end pre-bending, continuous bending without back Angle, bending process digital control man-machine dialogue control interface, efficient intelligent operation of physical bending process software, man-machine dialogue window, bending process automatic compensation. Single operation, efficient, safe, convenient and rich bending shape with winding O, U, R and other different shapes. Upper roll universal bending machine technical description: High precision end prebending W11S plate winding… Read More »W11S upper roll universal plate winding machine