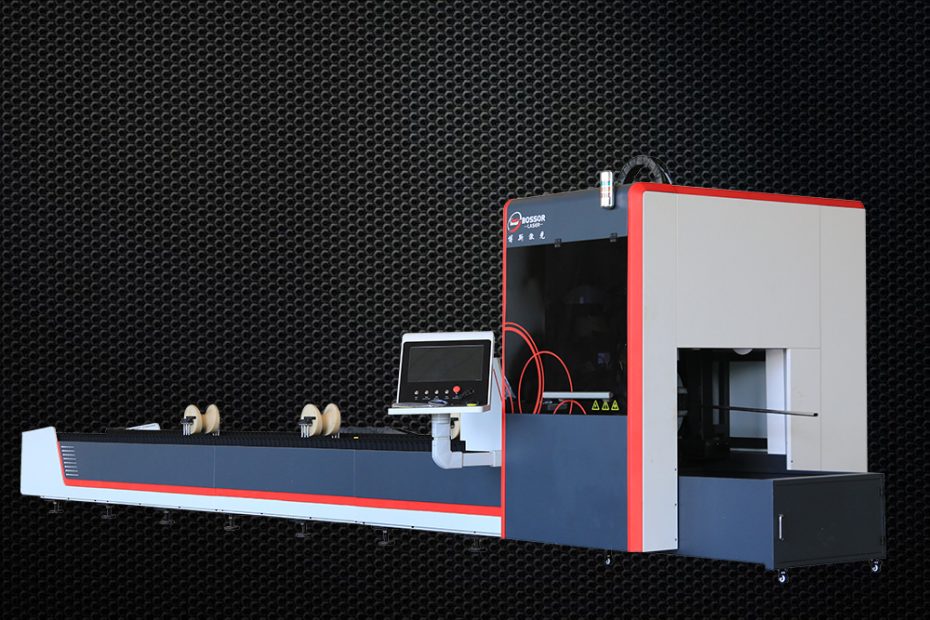

3015 fiber laser cutting machine Application scope: Rail transit, shipbuilding, automobile, construction machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, food machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchen bathroom, decoration advertising, laser external processing services and other machinery manufacturing and processing industries 3015 fiber laser cutting machine Iii. Electrical Part: 1. Electrical components adopt internationally famous brand products; For example: Schneider, ABB, Siemens, etc. 2. High standard sealing design for electric cabinet procurement to… Read More »3015 fiber laser cutting machine Application scope