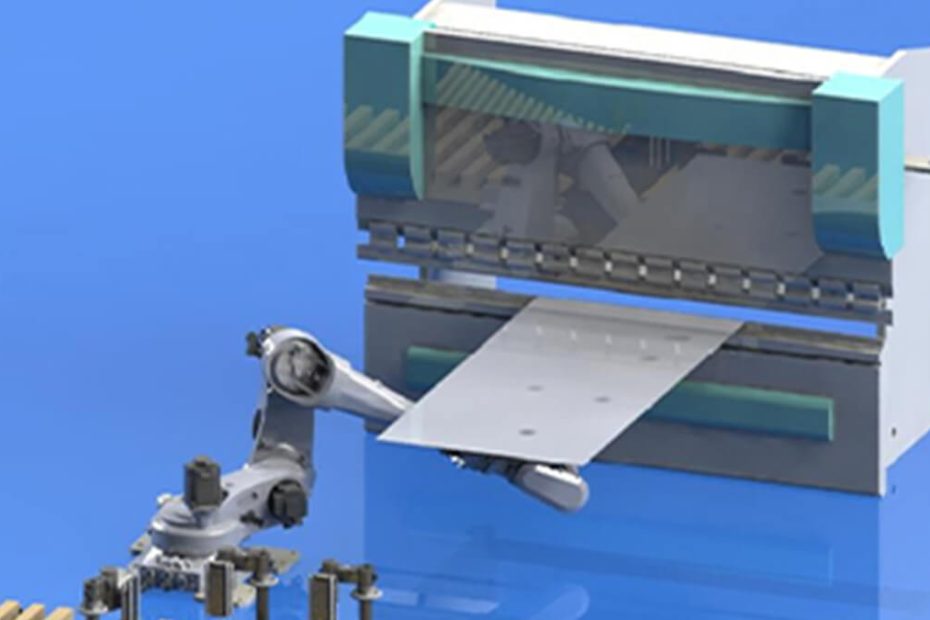

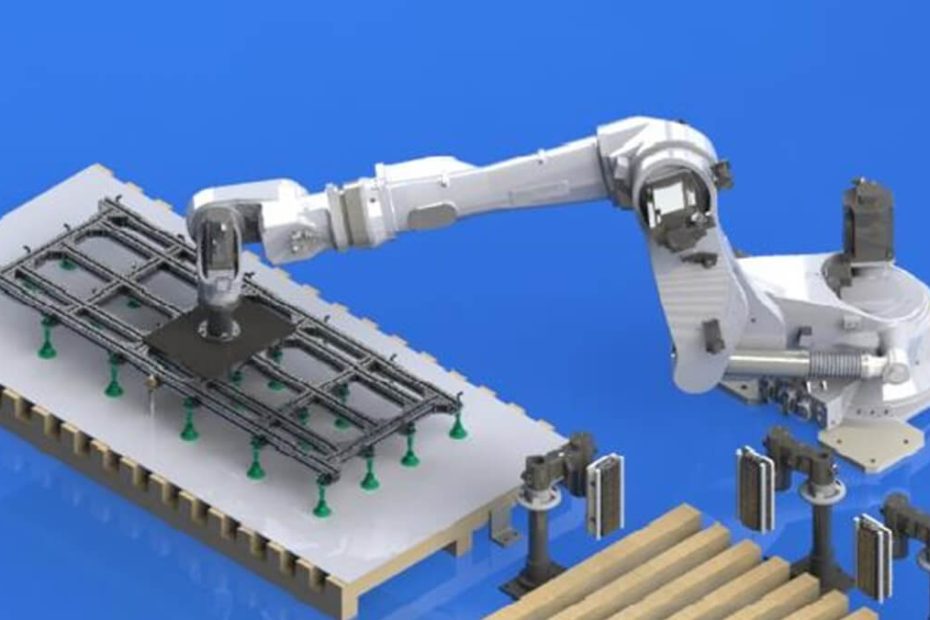

Sheet Metal Bending Bend Allowance Calculation Guide

In this article, I will share with you some insights into sheet metal bending and list some common mistakes in the sheet metal bending process and solutions to avoid these mistakes. Minimum flange length There is a minimum flange length for sheet metal bending. Refer to the bend force table for guidance. Choose the width of the die based on the thickness. If you design the flange too short, it will awkwardly “fall” into the gap and you won’t get… Read More »Sheet Metal Bending Bend Allowance Calculation Guide