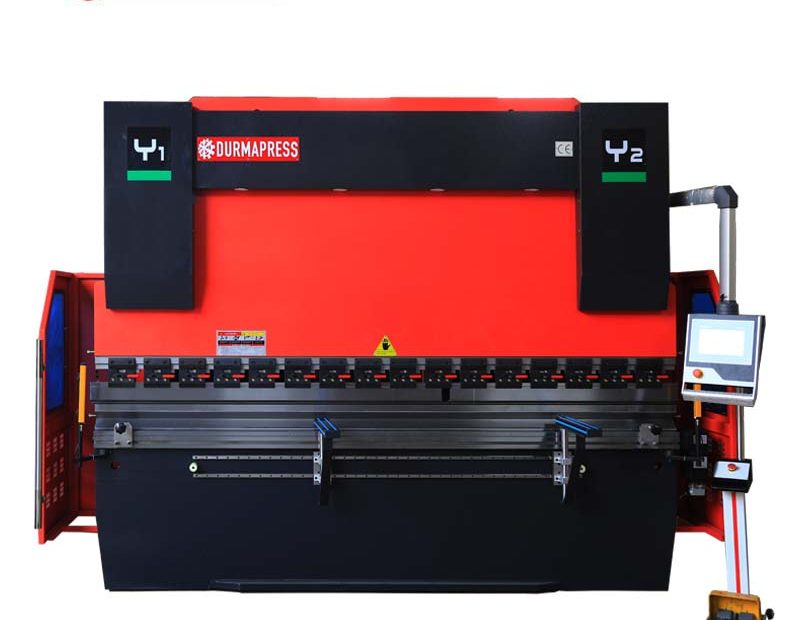

How to improve the productivity of QC12K- 12*2500 plate shears?

Many users rely on the purchase of important standard parts, can improve productivity to improve output, productivity can be expressed in many forms: save manpower, and improve logistics, improve accuracy, improve incision quality, avoid secondary operations, but in order to improve safety. Help to increase the output of products include QC12K- 12*2500 plate shears: Arm: For adjustment and straightening, depending on configuration can also be used as front guard and support long metal plate. Bracket: The support material for the… Read More »How to improve the productivity of QC12K- 12*2500 plate shears?