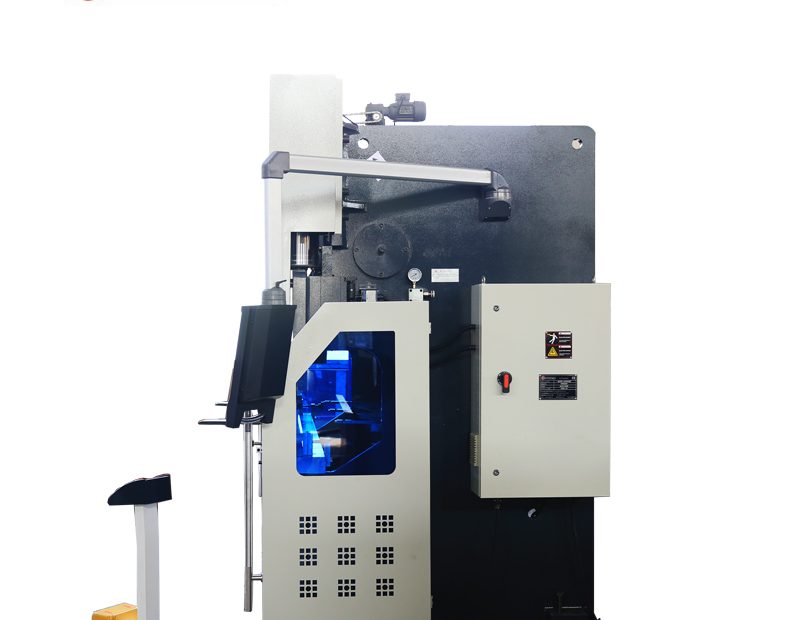

Hydraulic CNC bending machine main configuration-The main seals of the oil cylinder are produced by Japan Huarka Company

Hydraulic CNC bending machine main configuration: 1. The main seals of the oil cylinder are produced by Japan Huarka Company. 2. The main parts in the electric box are produced by Schneider in France. 3. The hydraulic system is controlled by cartridge valve, and the main hydraulic components are made by Germany Hoerbiger Company. 4, the hydraulic pump adopts aerospace standard low noise internal gear pump. 5. The oil cylinder processed by the manufacturer and the sealing ring imported in… Read More »Hydraulic CNC bending machine main configuration-The main seals of the oil cylinder are produced by Japan Huarka Company