The Future of Metal Processing: Creating Efficient Production Lines with Numerical Control Punch Presses and Robotic Arms

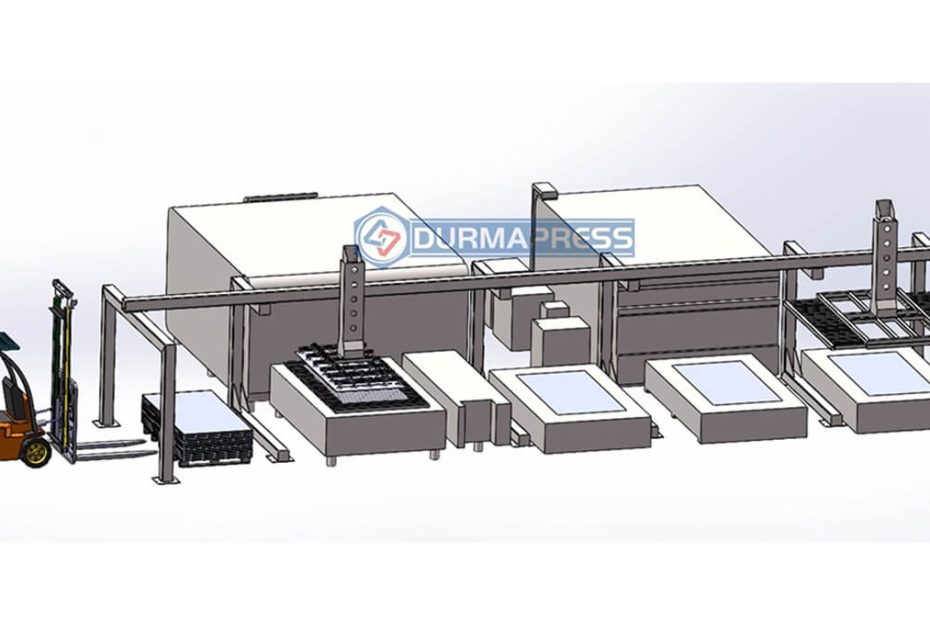

About Us Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry. Contact Us Recent Posts Categories Follow Us Facebook-f Twitter Youtube Linkedin Instagram Weekly New Video Pain Points of Traditional Stamping Production and Opportunities for Automation Transformation Drawbacks of Manual Material Handling… Read More »The Future of Metal Processing: Creating Efficient Production Lines with Numerical Control Punch Presses and Robotic Arms

-930x620.jpg)

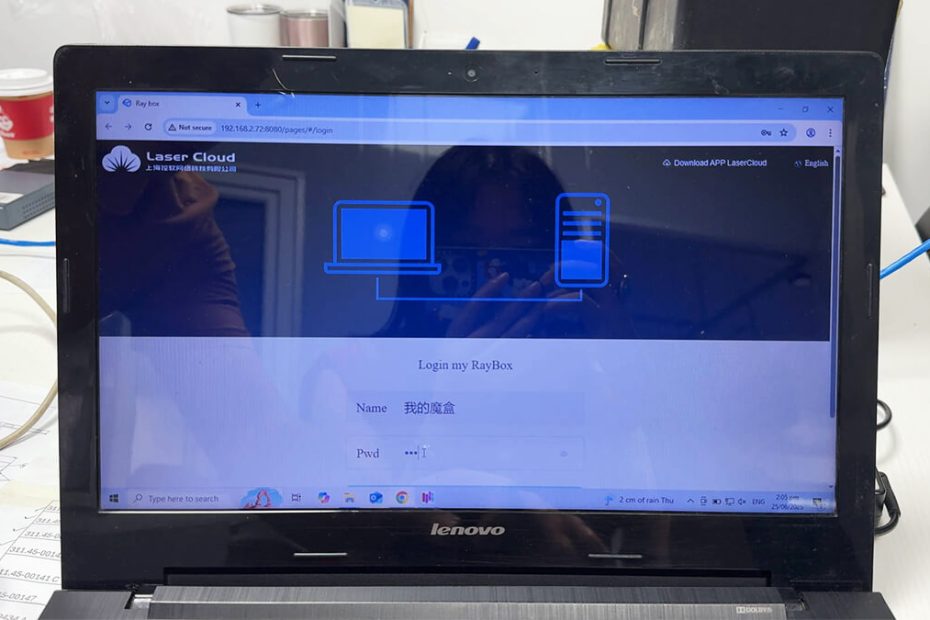

How-Can-The-MES-System-Eliminate-Inefficiency-In-Automotive-Sheet-Metal-Manufacturing-930x620.jpg)

-930x620.jpg)