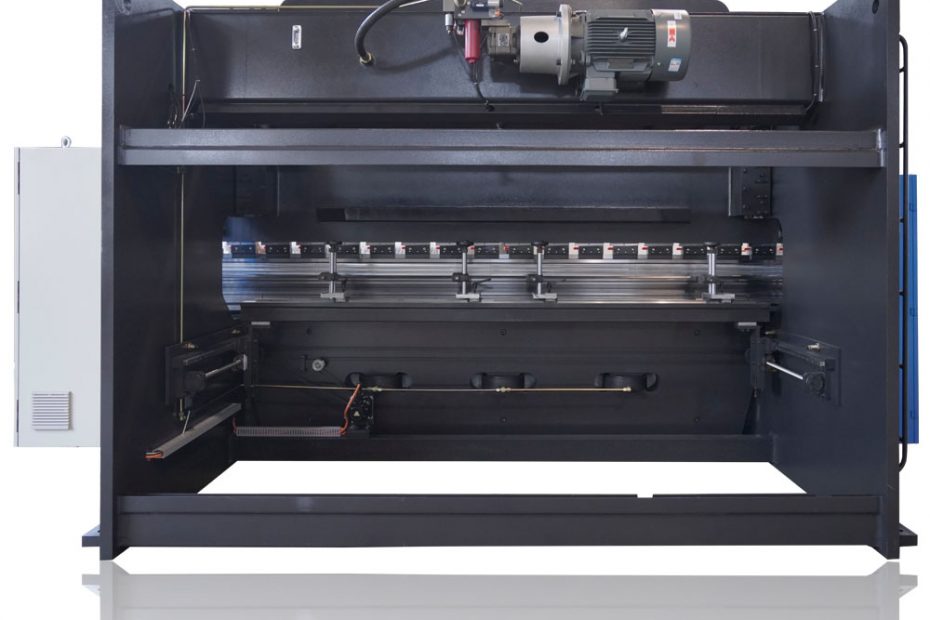

How to program high quality hydraulic press brake?

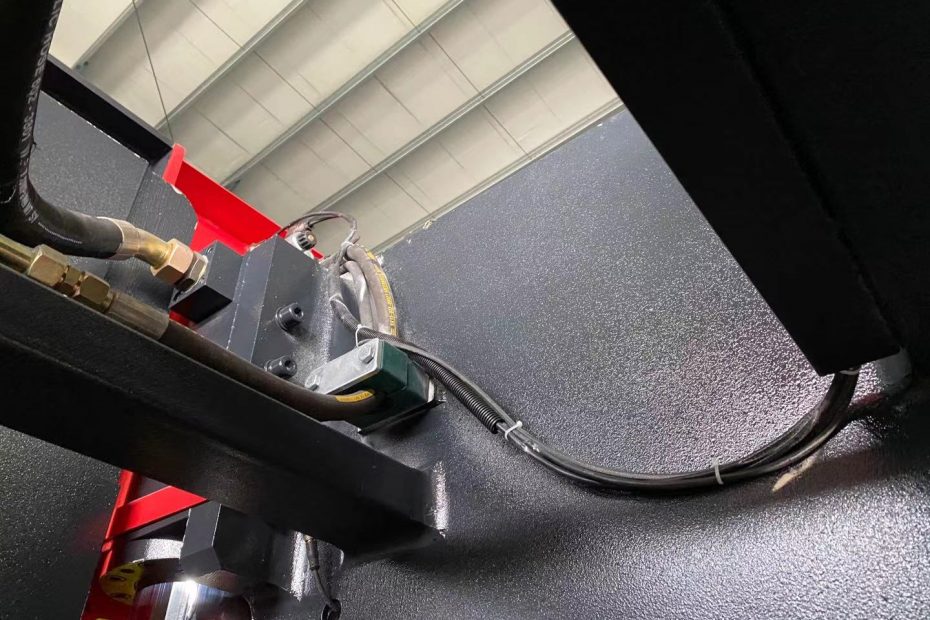

High quality hydraulic press brake is hydraulic transmission, so its slider part by the slider, cylinder and mechanical block fine tuning structure of the bending machine about the cylinder is fixed on the frame, through hydraulic piston to drive the slider up and down, mechanical block by numerical control system control adjustment value. CNC bending machine stroke adjustment, the use of must pay attention to the adjustment of stroke, must be tested before folding check. Its upper die down to… Read More »How to program high quality hydraulic press brake?