DURMAPRESS WC67K-125T3200 Hydraulic Press Brake machine processing need to pay attention to the situation

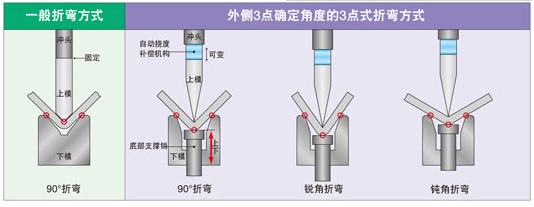

DURMAPRESS WC67K-125T3200 Hydraulic Press Brake machine processing need to pay attention to the situation: 1. Vibration, because there is a small gap between the bending machine and the knife clip, so in the process of processing the knife may appear vibration phenomenon 2. Clamping, machining center with the bending machine mostly adopts the spring clamping set clamping mode, when using in a cantilever state. 3. End edge cutting, CNC milling machining of workpiece cavity such as mold, when the cutting… Read More »DURMAPRESS WC67K-125T3200 Hydraulic Press Brake machine processing need to pay attention to the situation