How To Improve Bending Accuracy

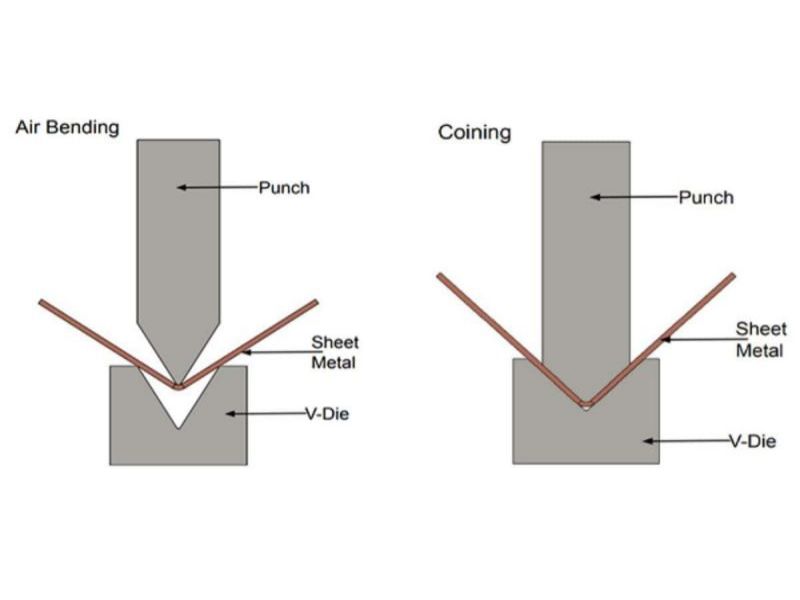

he mold is the primary factor affecting the bending accuracy. The mold is the main tool for bending the workpiece. The shape and size of the bent part mainly depends on the dimensional accuracy of the working part of the mold.

-930x620.png)