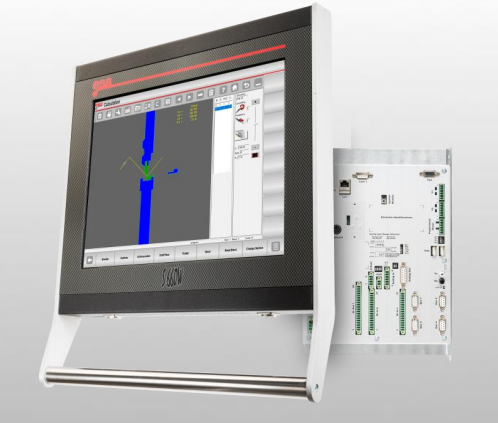

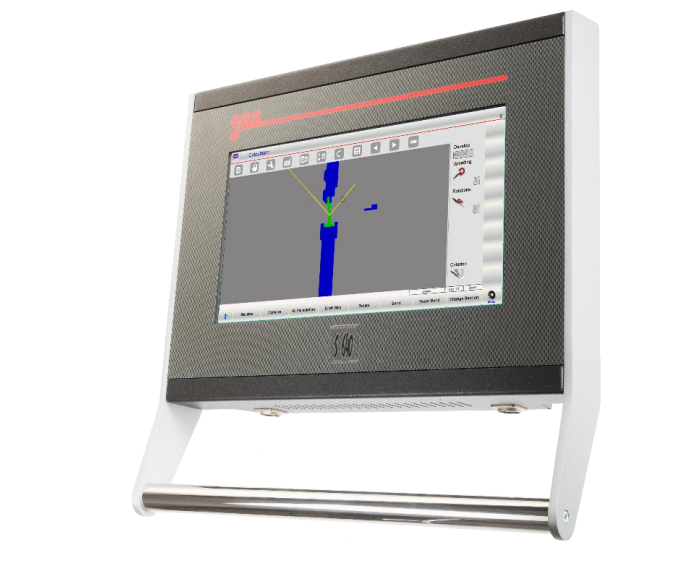

QC11X(K) hydraulic (NUMERICAL control) gate plate shearing machine

QC11X(K) series hydraulic (NUMERICAL control) gate type plate shearing machine ★ Adopt all steel welding structure, stress treatment after welding, have enough strength and rigidity. ★ Series cylinder structure, good synchronization performance. ★ With rolling clamping guide rail, not only the tool rest runs smoothly, but also can quickly adjust the blade gap. Tool rest stroke can be stepless adjustment to improve production efficiency. The upper tool rest adopts internal inclined structure, easy to blanking, improve the accuracy of the… Read More »QC11X(K) hydraulic (NUMERICAL control) gate plate shearing machine