How To Choose Between Robot Bending Unit And Panel Bender?

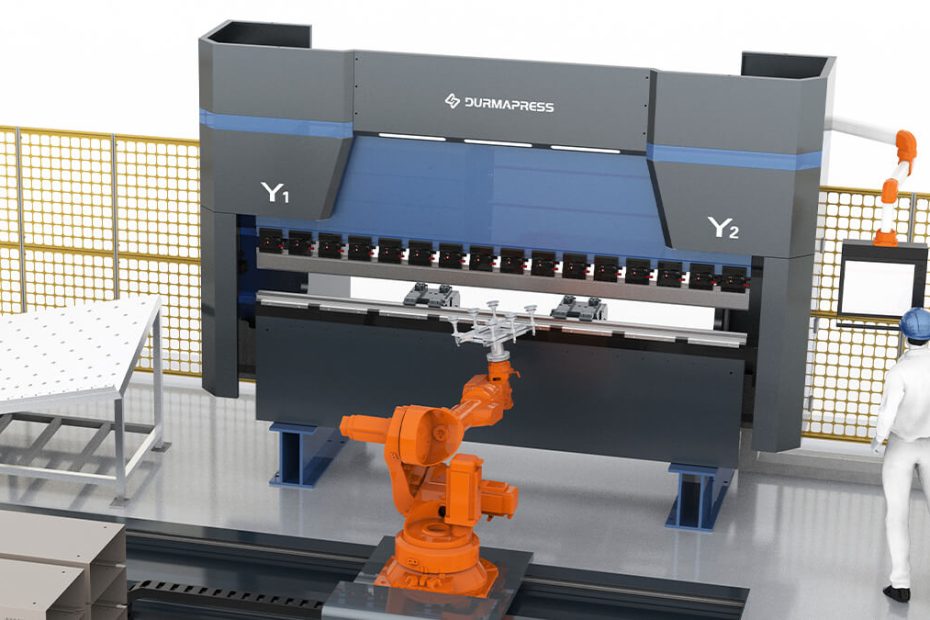

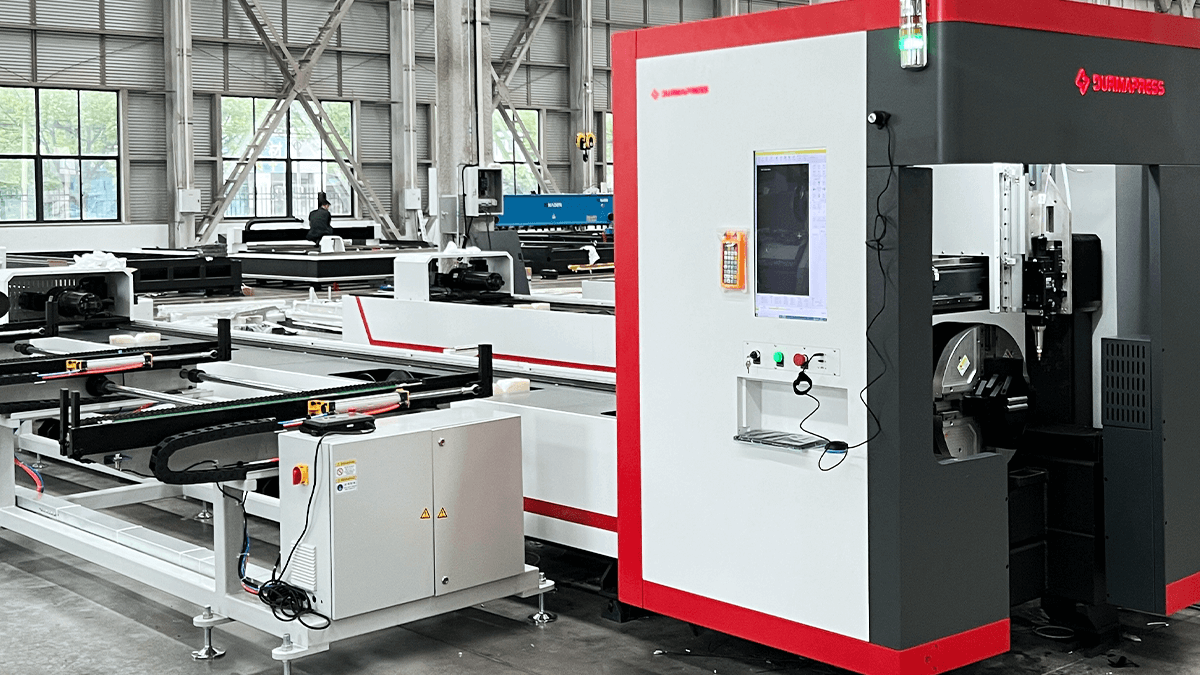

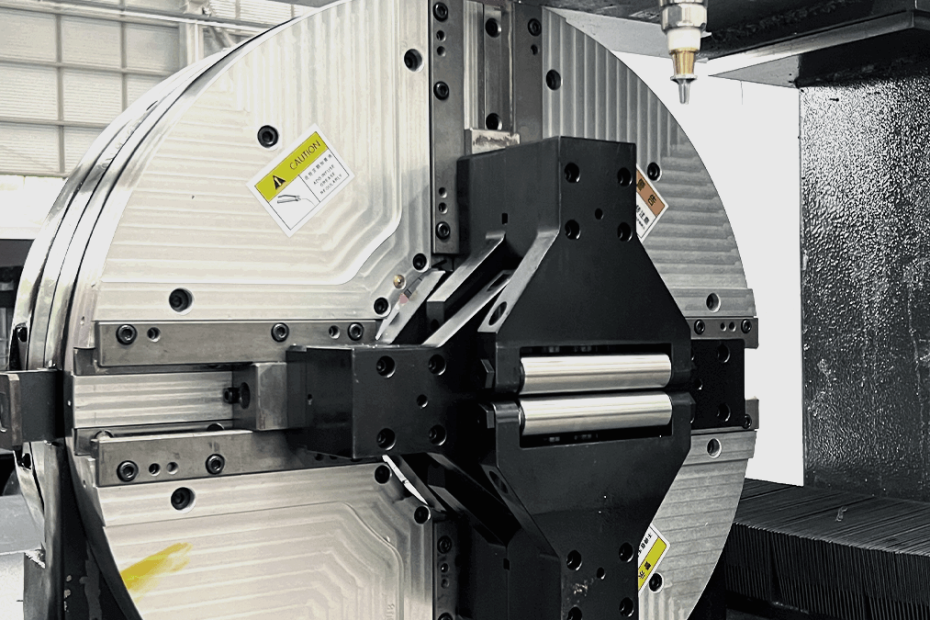

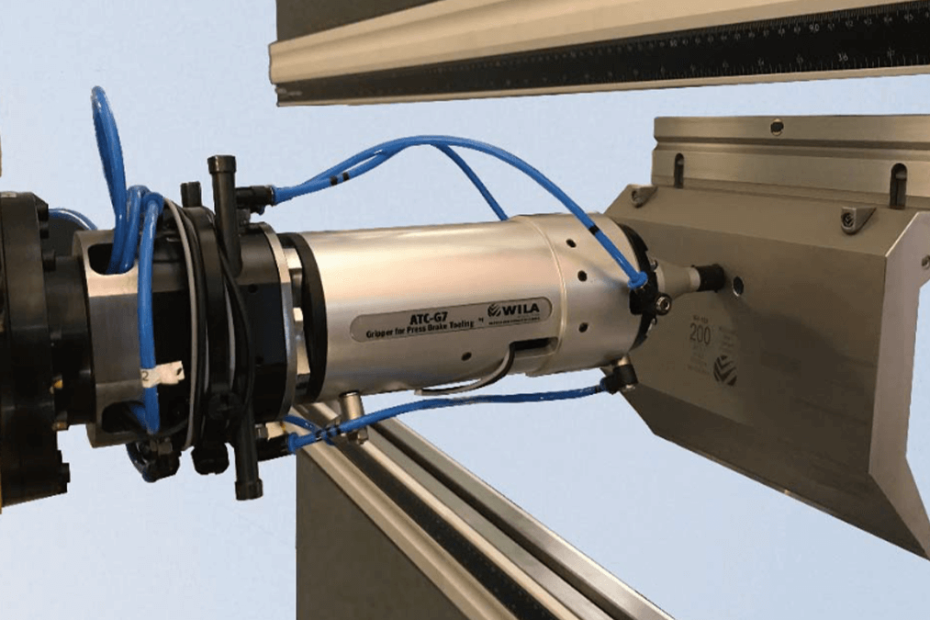

With the rapid development of sheet metal production towards automation and intelligence, the application of robot bending units and panel benders is becoming more and more popular. So how do companies choose?To know how to choose, we must first understand the problems that need to be solved in the sheet metal bending industry and how the robot bending unit and the panel bender perform sheet metal bending? Problems that the sheet metal industry currently needs to solve Let's first talk about… Read More »How To Choose Between Robot Bending Unit And Panel Bender?