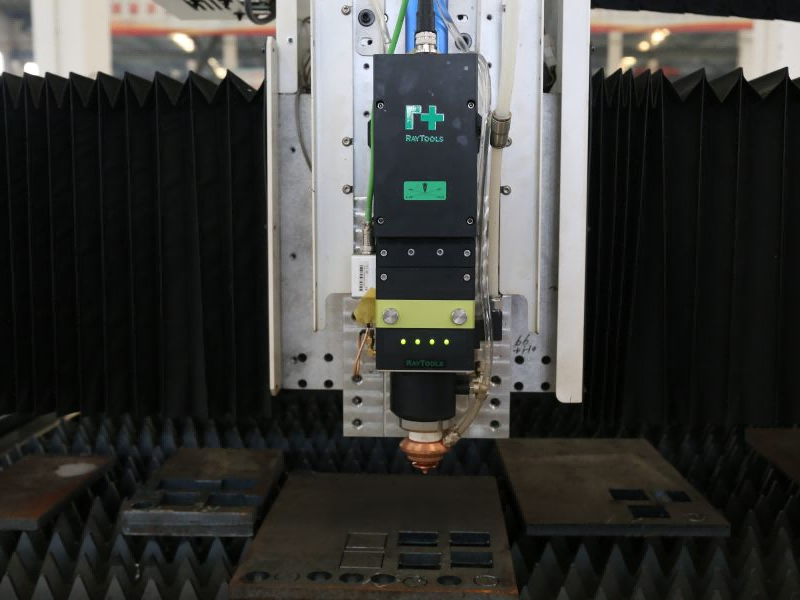

Exploring the Power of Fiber Laser Cutting Machines: A Guide to 1000KW to 3000W Models

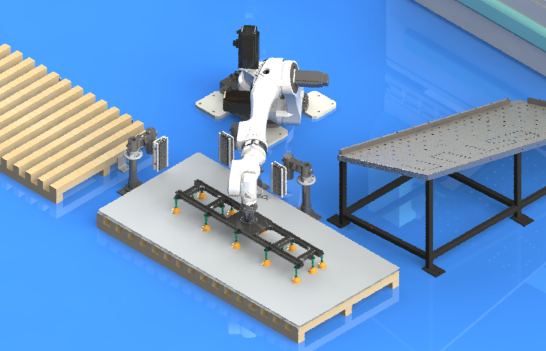

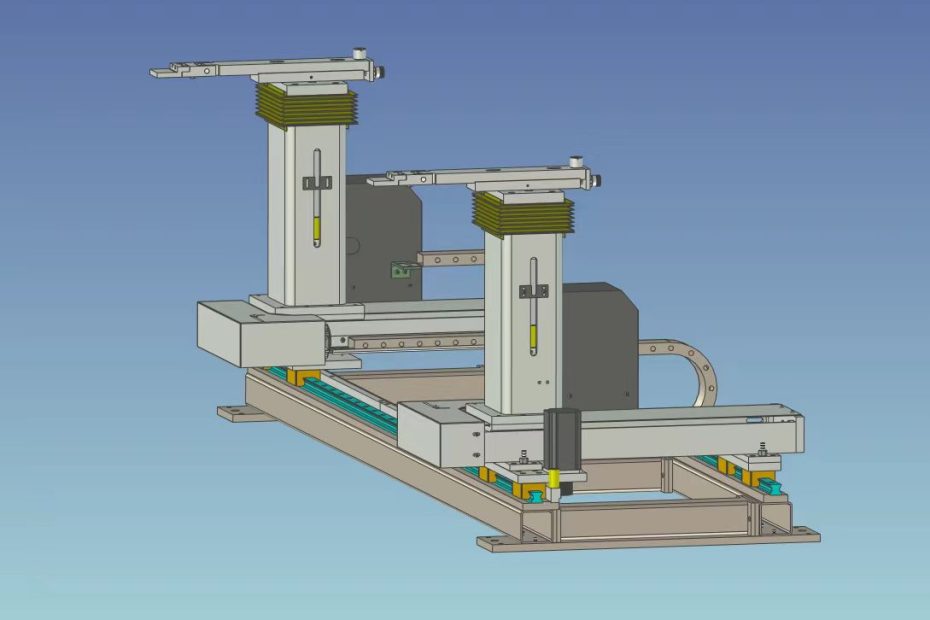

Laser cutting machines play a very important role in modern production, especially in manufacturing and industrial production, significantly improving cutting efficiency. This paper focuses on the importance of laser cutting machines in production, with a specific focus on four types: 1000W, 1500W, 2000W, 2500W , all powered by a medium power continuous fiber laser.