Common Faults and Repairs of Automatic CNC Pipe Bending Machines

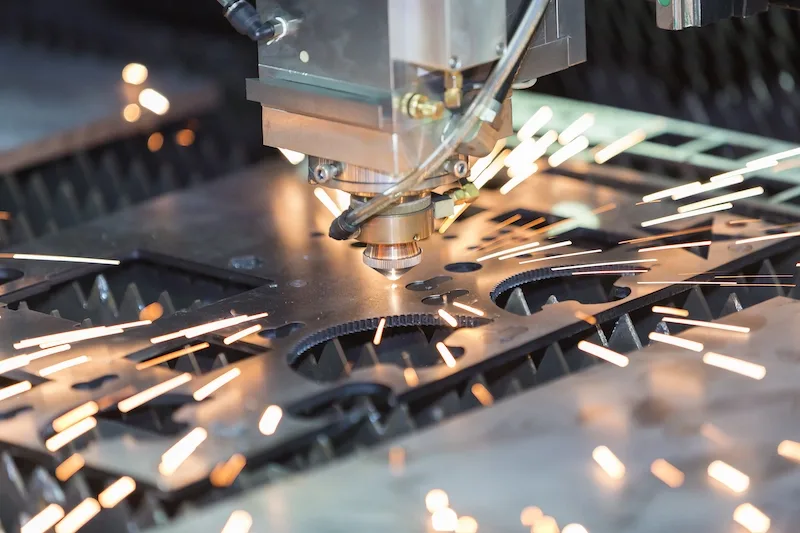

As one of the important equipment in the field of modern metal processing, automatic CNC tube bending machines are widely used in aerospace, automobile manufacturing, construction and other industries with their high-precision and high-efficiency tube bending capabilities.