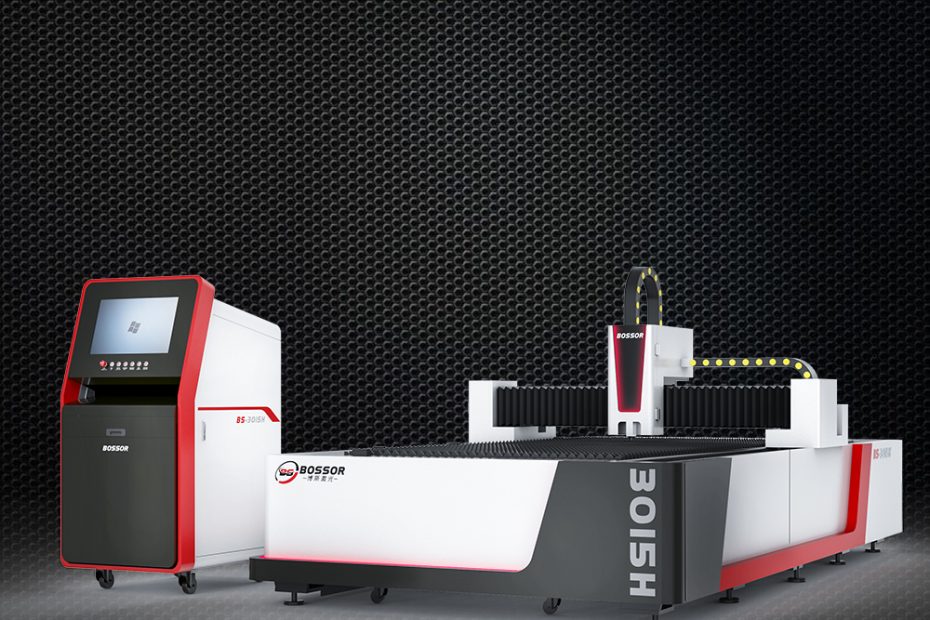

The influence of BS6020G-6000W Fiber Laser Cutting Machine gas and pressure on cutting quality

1) When the pressure of cutting gas is insufficient, it will cause the following effects on cutting quality: when cutting, it will produce melting stains, and the cutting speed can not meet the requirements of production efficiency.

2) when the cutting gas pressure is too high, the impact on the cutting quality: the cutting surface is rough, and the slit is wider; At the same time, it will cause partial melting of the cutting section, which can not form a good cutting section.

3) Cutting gas helps heat dissipation and combustion, blowing off the melting stain, so as to get a good quality cutting section.

Effect of cutting gas pressure on perforation

1) Laser drilling, generally for thin plate parts with higher gas pressure, and for thick plate parts with a specific way of punching, to eliminate the protection of low pressure on the lens adverse factors.

2) When the gas pressure is too high, causing the penetration point to melt, forming a larger melting point, thus affecting the quality of cutting.

3) When the gas pressure is too low, the laser is not easy to penetrate the cutting plate, the drilling time increases, resulting in low productivity.